Spherical hinge rubber elastic element rigidity changing method, and rubber elastic element and manufacturing method thereof

A technology of elastic elements, rubber elastomers, applied in the direction of spring/shock absorber functional characteristics, spring, spring/shock absorber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

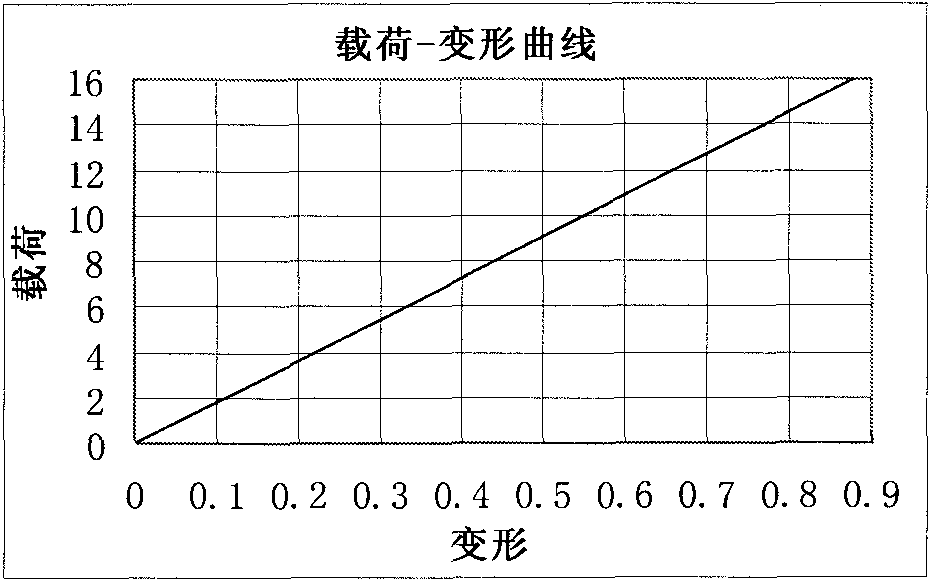

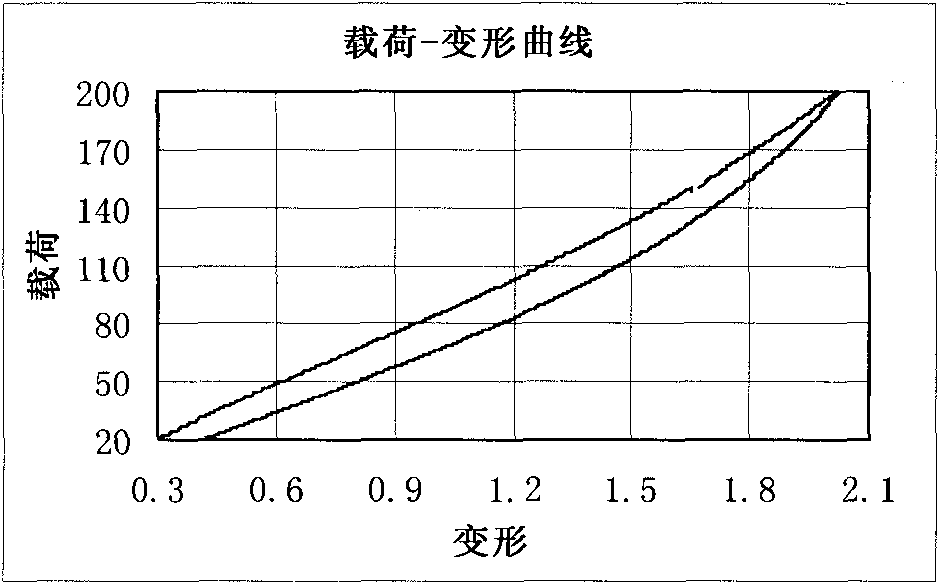

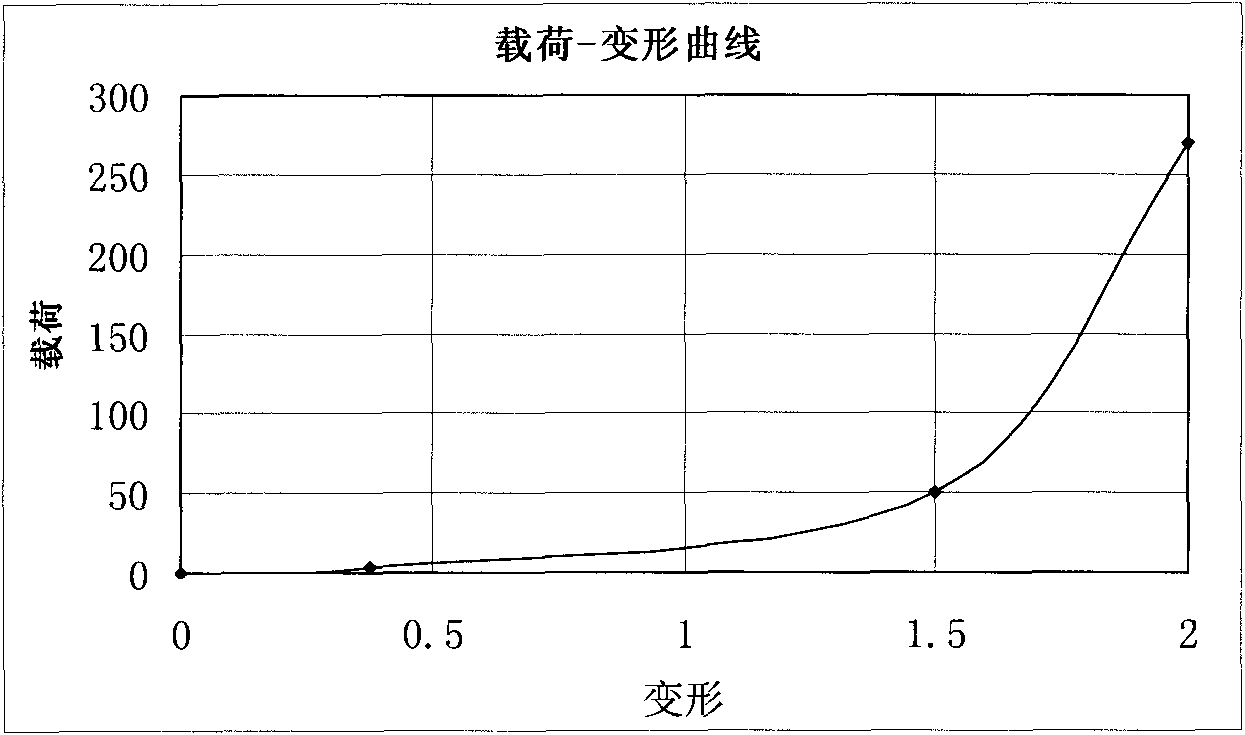

[0028] by attaching Figure 4 It can be seen that the present invention is a ball joint-type rubber elastic element, which adopts a method of symmetrically removing part of the rubber material and sealing the space where the rubber is located to the greatest extent, through the contact surface and the limited degree of rubber deformation in different stress stages. The size of provides different stiffness, so as to achieve variable stiffness. Its characteristics are: the symmetrical removal of part of the rubber material is to dig out 3-5 annular spaces on the surface of the rubber elastic body along the circumferential direction, so that after the rubber elastic body is combined with the outer metal sleeve At the same time, there is only partial contact between the outer metal sleeve and the rubber elastic body, and there are 3-5 circular air isolation areas, and the space for the rubber to bulge at both ends is very small; at the same time, the rubber elastic body is assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com