Flexible screen mounting structure and flexible LED display screen

A technology of LED display screen and installation structure, which is applied in the direction of lighting devices, identification devices, lighting and heating equipment, etc., and can solve the problems of easy damage, storage, inconvenient transportation, movement, transportation, and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

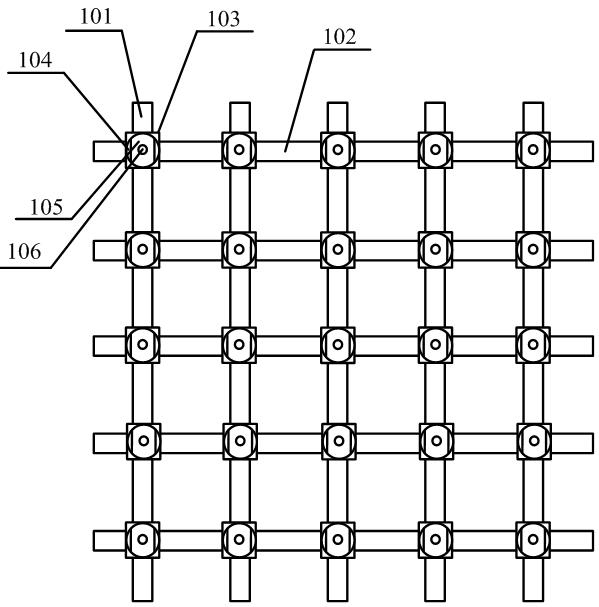

[0024] Such as figure 1 As shown, this embodiment provides a flexible screen body installation structure, the flexible screen body installation structure includes a flexible installation belt and several installation units; the flexible screen body installation structure is used to install each LED unit, and each The LED units form a flexible LED display screen, which is used to display various graphics, characters, letters, video animations, etc.

[0025] The flexible installation belt is a grid-shaped flexible installation belt composed of several horizontal bars 102 and some vertical bars 101 fixedly connected to each other. For example, each horizontal bar 102 and each vertical bar 101 can be fixed to each other by setting a fixing device; The shaped flexible mounting belt has the characteristics of being foldable at will, transparent, good heat dissipation effect, and light in size.

[0026] The flexible installation belt is made of soft material, which can be folded and...

Embodiment 2

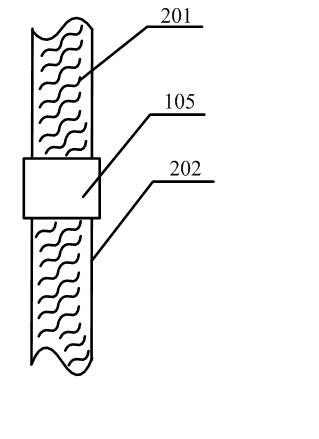

[0035] Such as figure 2 As shown, on the basis of the above examples, in the flexible screen installation structure provided in this embodiment, a number of anti-skid teeth 201 are also provided on the surface of the flexible installation belt 202, wherein each anti-skid tooth 201 can be set as the The tooth-shaped protrusions on the surface of the flexible installation belt, by setting the anti-slip teeth 201, can increase the sliding resistance between each installation unit 105 and the flexible installation belt 202, so that when installing and dismounting each installation unit, it is avoided due to the large sliding range. , so that the positions of each installation unit 105 and the flexible installation belt 202 are difficult to fix, increasing the difficulty of installation and disassembly, especially during installation; and each anti-slip tooth 201 can also make each LED unit and the flexible installation belt The fixing of 202 is more stable.

[0036]And, the shap...

Embodiment 3

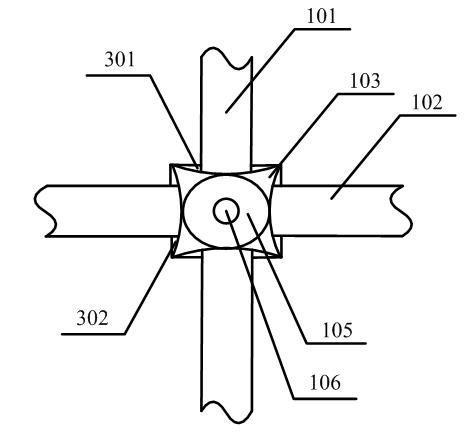

[0038] Such as image 3 As shown, on the basis of the above examples, in the installation structure of the flexible screen provided in this embodiment, the moving positioning sleeve 103 is provided with one or more first sets of holes 302 along the transverse direction and one or more second sets of holes 302 along the longitudinal direction. Two sets of holes 301, wherein, the first set of holes 302 is used for nesting each horizontal bar, and the second set of holes 301 is used for nesting each of the vertical bars; by setting the first set of holes 302 and the second set of holes 301, it is possible to Make each installation unit 105 move laterally along each horizontal bar relative to each vertical bar, thereby changing the lateral spacing of its correspondingly installed LED units, and make each installation unit 105 move longitudinally relative to each horizontal bar along each vertical bar, thereby It is possible to change the longitudinal spacing of the corresponding i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com