Method utilizing mirror-polishing process to manufacture aviation organic glass window

A plexiglass window and mirror polishing technology, which is applied to machine tools, manufacturing tools, grinding/polishing equipment, etc., which are suitable for grinding workpiece planes, and can solve problems such as reduction of visible area, accumulation, and possibility of increasing silver streaks , to maximize the viewing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

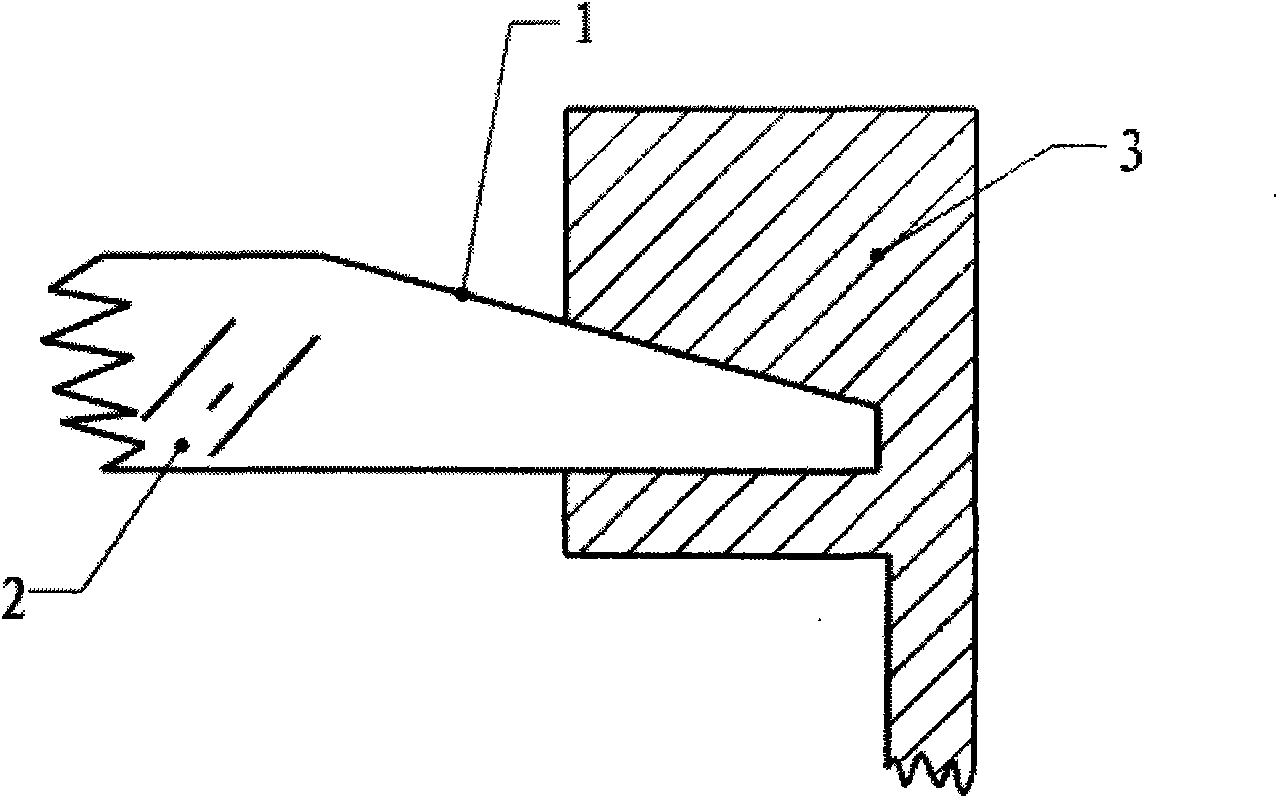

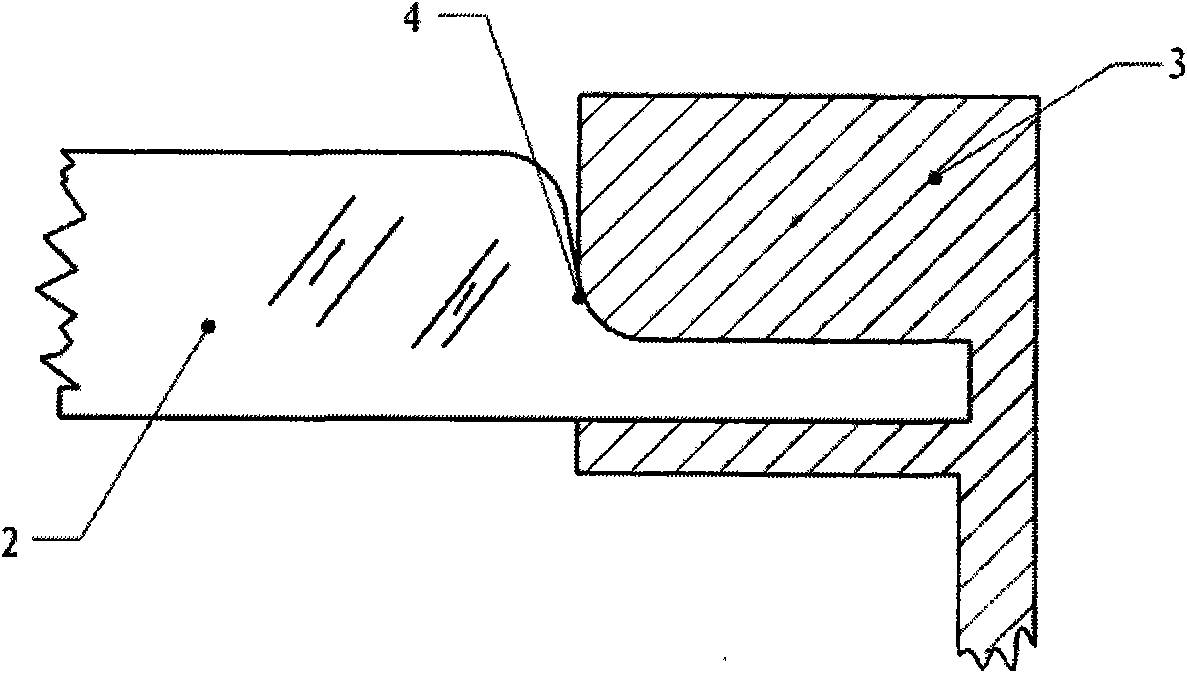

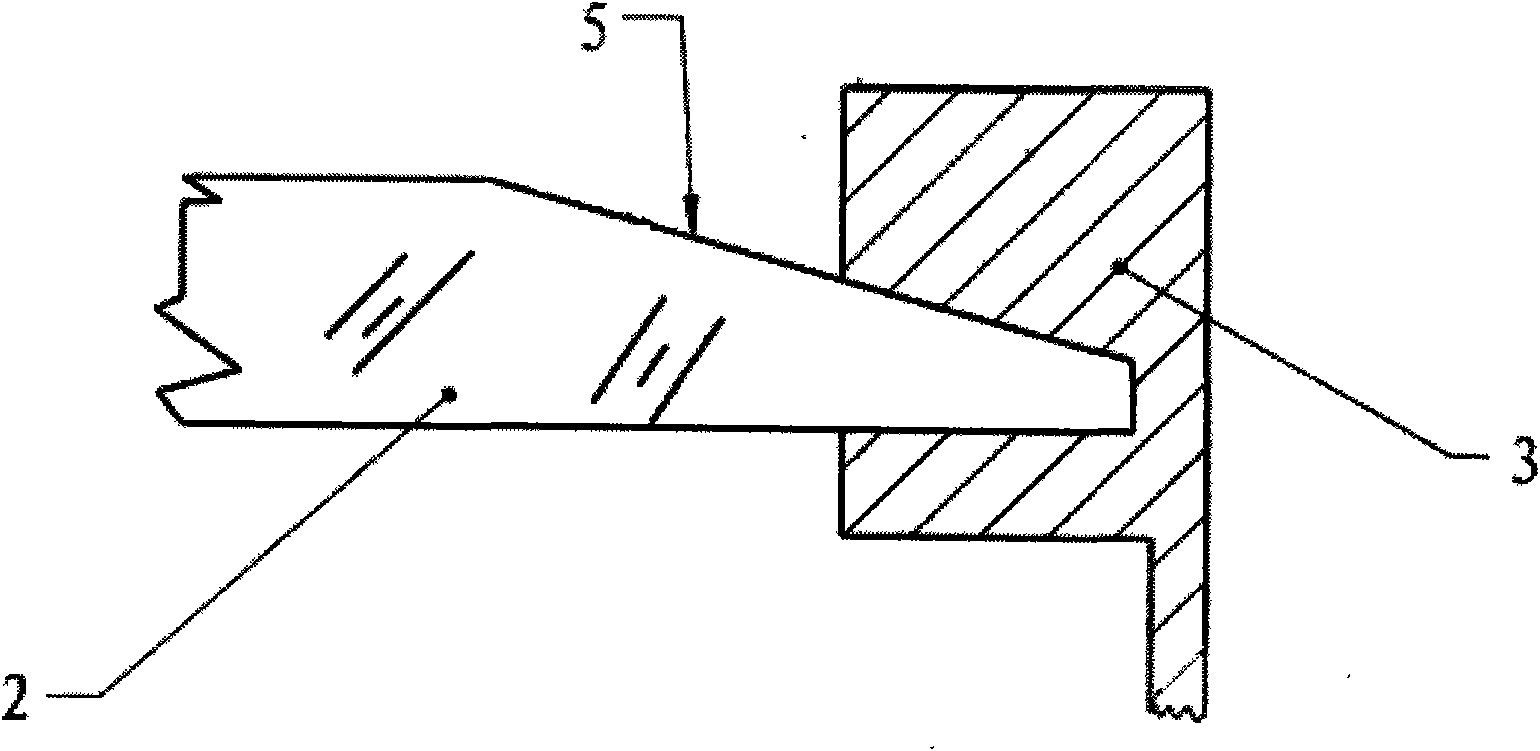

[0017] Such as image 3 Shown, the method that the present invention adopts utilizes mirror polishing process to manufacture aviation plexiglass window. Firstly, the thickness of the aviation glass window 2 is determined according to the requirements of vision, high-altitude operation strength and the strength of bonding with the window frame, and the aviation organic glass window 2 is processed by a 360-degree multi-directional stretching process. Secondly, according to the plane size and shape of the aviation plexiglass window 2 set, the aviation plexiglass window 2 that has been processed with a 360-degree multidirectional stretching process is cut, wherein the aviation plexiglass edge 5 is processed into a stepped shape. Finally, the 5-coordinate processing technology is adopted to mirror-polish the edge portion 5 of the aviation plexiglass window, so that the edge portion 5 of the aviation plexiglass window is visible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com