Process for die-pressing and shaping cup and die

A cup and molding technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problem of difficulty in achieving the effect of fiber cotton cups, and achieve the effects of strong hygroscopicity, not easy to yellowing, and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

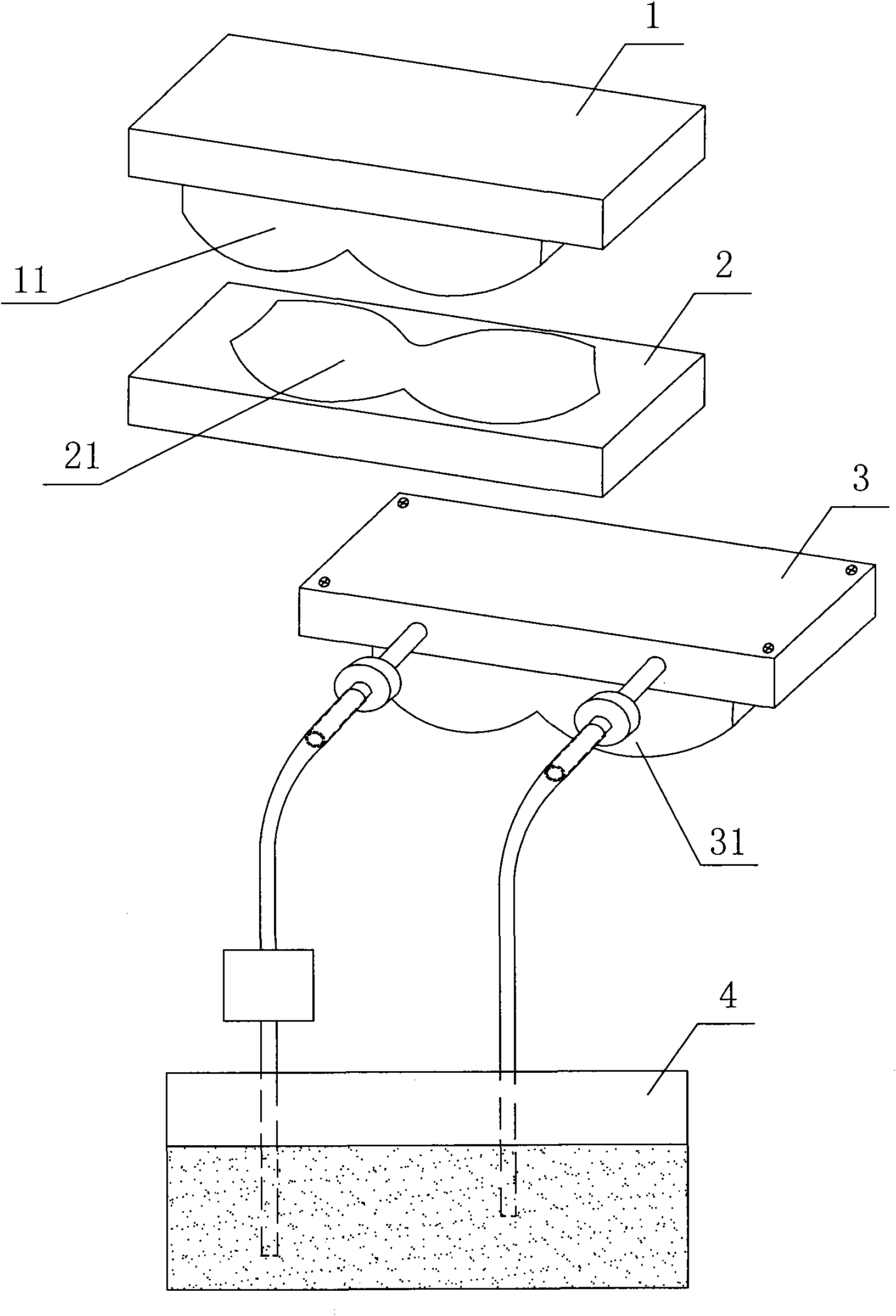

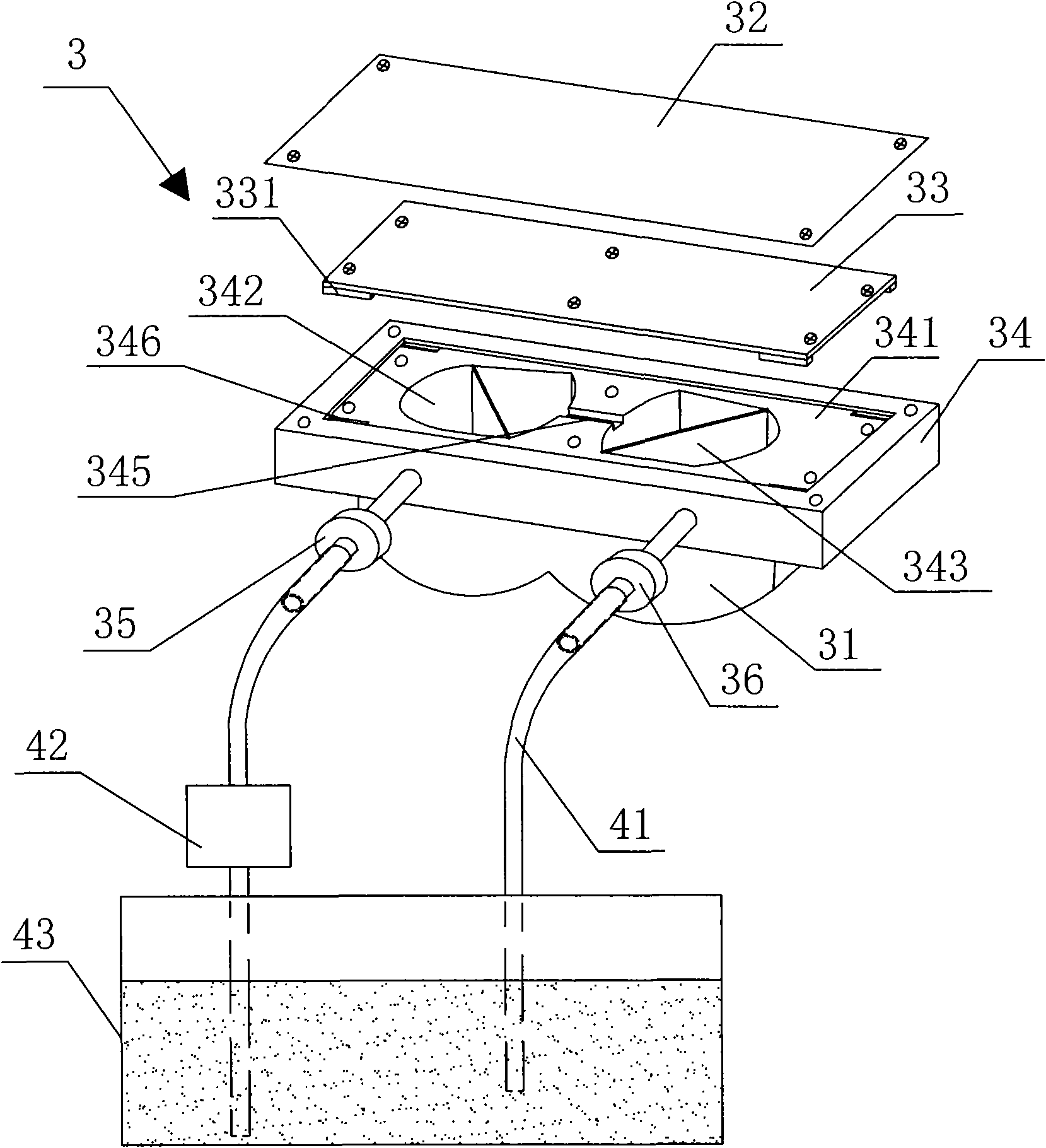

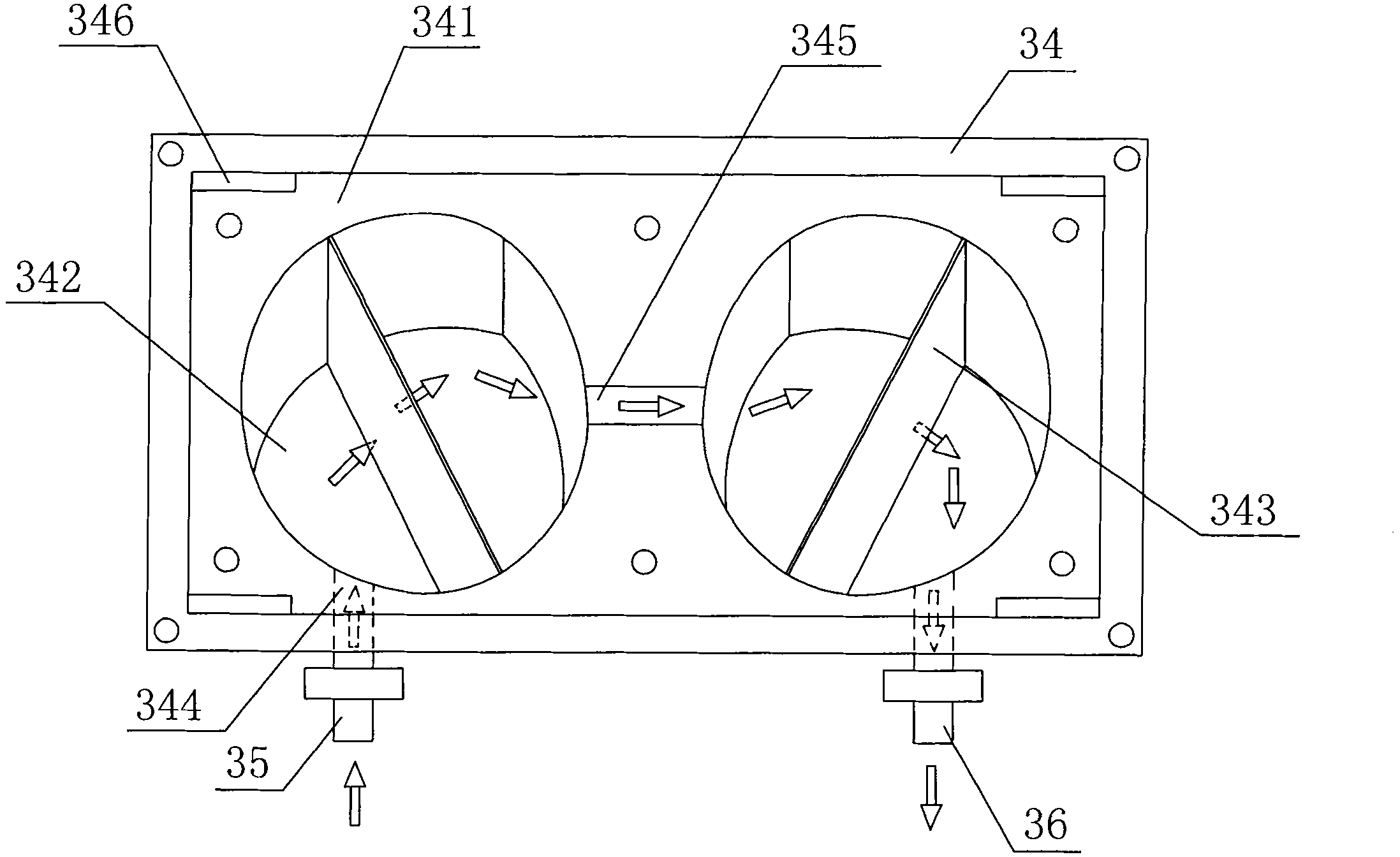

[0020] see Figure 1-4 Shown, a kind of mold of molded shaping cup, it comprises heatable cup molding upper mold 1, heatable cup molding lower mold 2, cold setting mold 3 and circulating water supply device 4, the upper mold of described cup molding lower mold 2 The end surface is concavely provided with a concave portion 21 having the same shape as the two bra cups, and the lower end surface of the cup molding upper mold 1 is convexly provided with a convex portion 11 that matches the shape of the upper end surface concave portion 21 of the cup molding lower mold 2. The cup molding upper mold 1 It is in contact with the cup molding lower die 2, and the lower end surface of the cold setting die 3 is convexly provided with a cold fixed convex portion 31 that matches the shape of the upper end surface concave portion 21 of the cup molding lower die 2. The cold setting die 3 and the circulating water supply The device 4 is plugged and fixedly connected.

[0021] The cold setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com