Gland-type packaging box

A packaging box and gland-type technology, applied in the field of gland-type packaging boxes, can solve the problems of uneven buckle tightness, difficulty in grasping the strength, and inconvenient opening, etc., and achieve the effects of easy processing and manufacturing, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

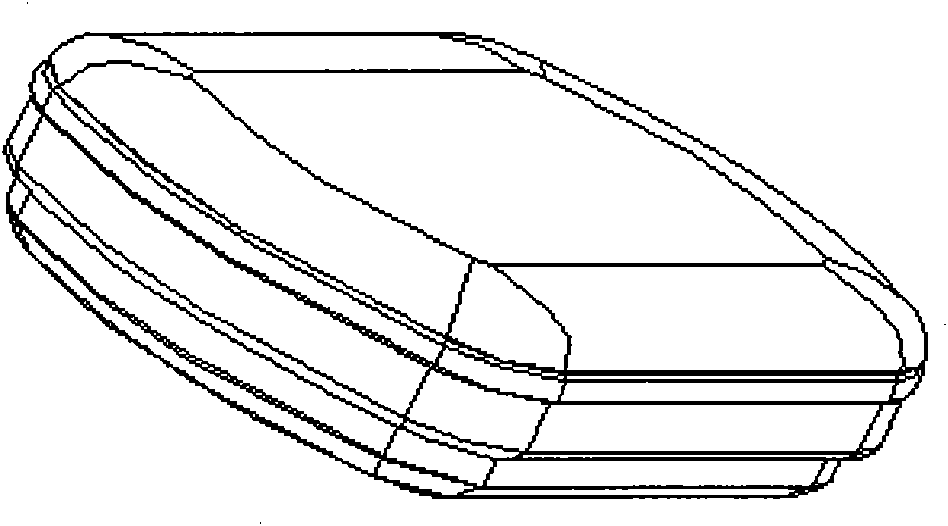

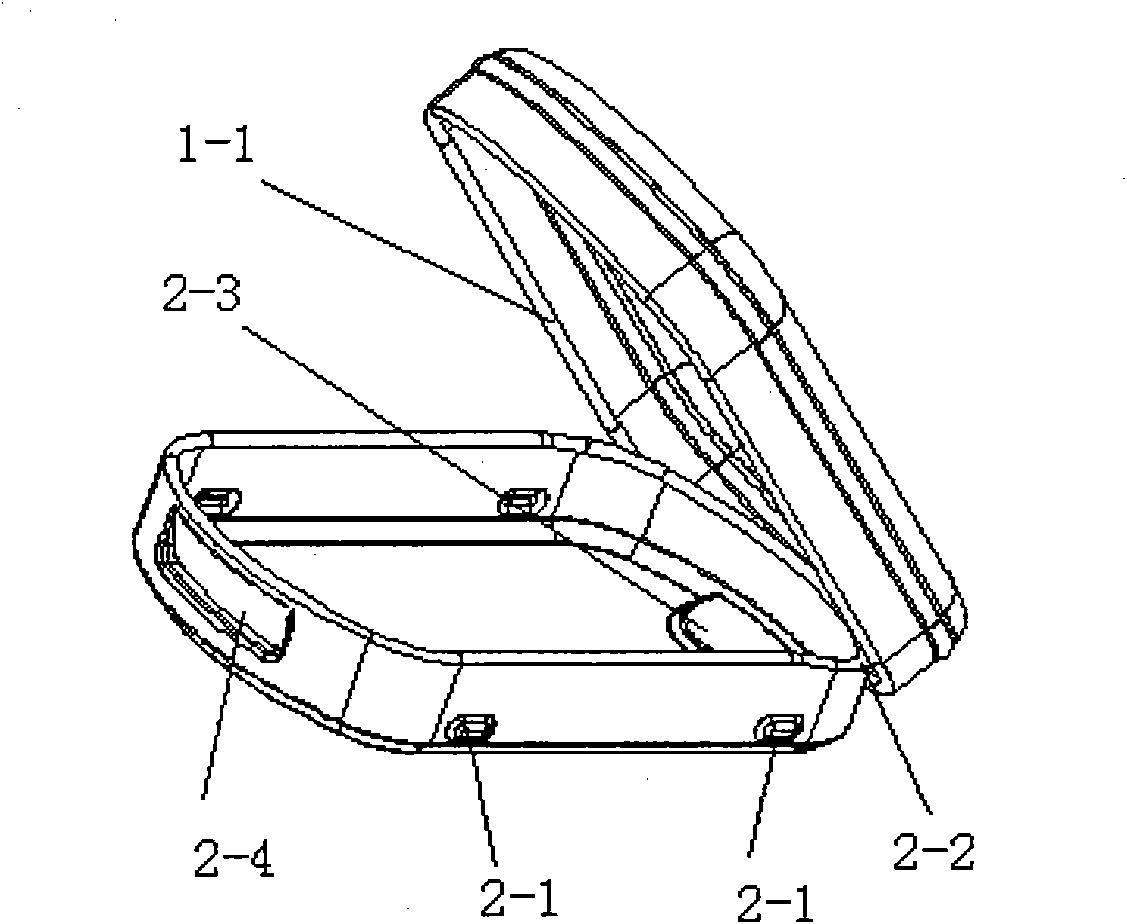

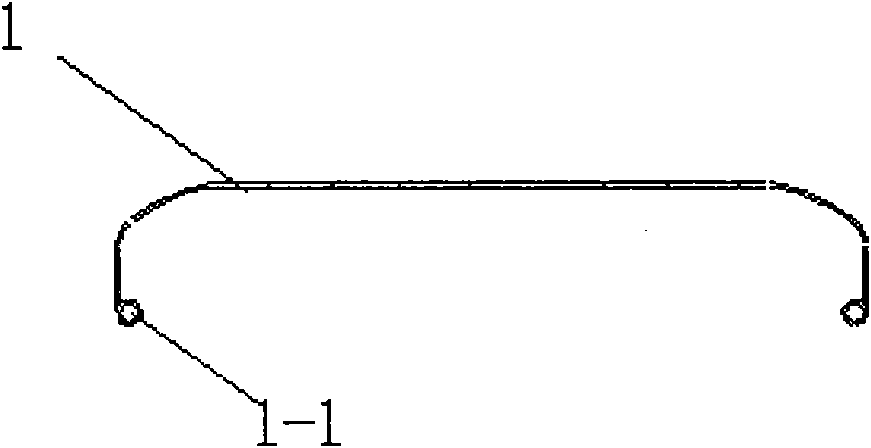

[0019] Such as figure 2 , image 3 As shown, the gland packing box of the present invention includes a box body 2 and a box cover 1. The outer sides of the front and rear side walls of the box body 2 are respectively provided with two spaced apart from the inner curling edge 1-1 of the box cover. The locking positioning protrusion 2-1, one of the left and right side walls of the box body 2 has a wedge-shaped end 2-2, and the bottom of the corresponding end of the box body is provided for pressing when opening the cover. The concave block 2-3; the outer side of the side wall at the other end of the box body 2 is provided with a concave groove 2-4 for opening the box cover.

[0020] When the user opens the box cover 1, his fingers press the recessed block 2-3 and the end of the box cover 1 corresponding to it. The other end of the box cover 1 slips off one of the positioning protrusions 2-1 and tilts upward. When the box cover 1 and the box body 2 are in a pre-opened state, the us...

Embodiment 2

[0023] Except for the following features, other features of this embodiment are the same as those of Embodiment 1:

[0024] Such as Figure 4 , Figure 5 , As shown, the side walls at both ends of the box body 2 can be set to wedge-shaped ends 2-2, 2-5, that is, the middle side wall of the box body 2 is higher than the end side walls, and the two positioning protrusions 2-1 There is a guide protrusion 2-6 in the middle and upper part of the side wall.

[0025] The distance between the positioning protrusion 2-1 at one end of the concave block 2-3 and the guide protrusion 2-6 is shorter than the distance between the other positioning protrusion 2-1 and the guide protrusion 2-6 Great distance.

[0026] In order to enable a better fit between the box cover 1 and the box body 2, the positioning protrusion 2-1 near one end of the recessed block 2-3 is spherical, and its protrusion height is higher than that of the other positioning protrusion 2- 1 The protrusion height is large.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com