Large super-wide metal pattern etching machine

An etching machine and ultra-wide technology, which is applied in the field of large-scale ultra-wide metal pattern etching machines, can solve the problems of troublesome opening and closing, poor sealing effect, complicated processing, etc., and achieve less workshop occupation, convenient maintenance, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best implementation examples

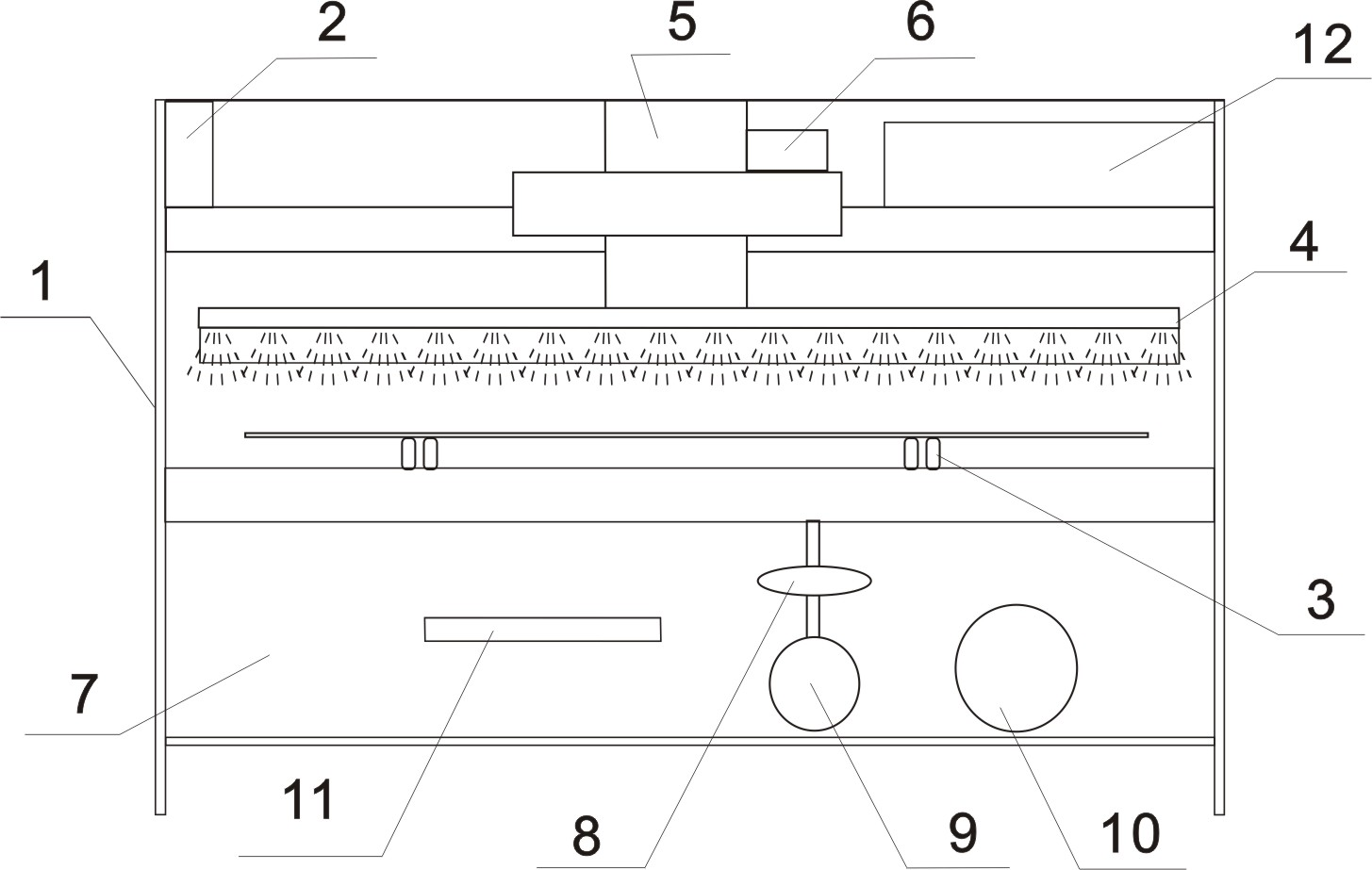

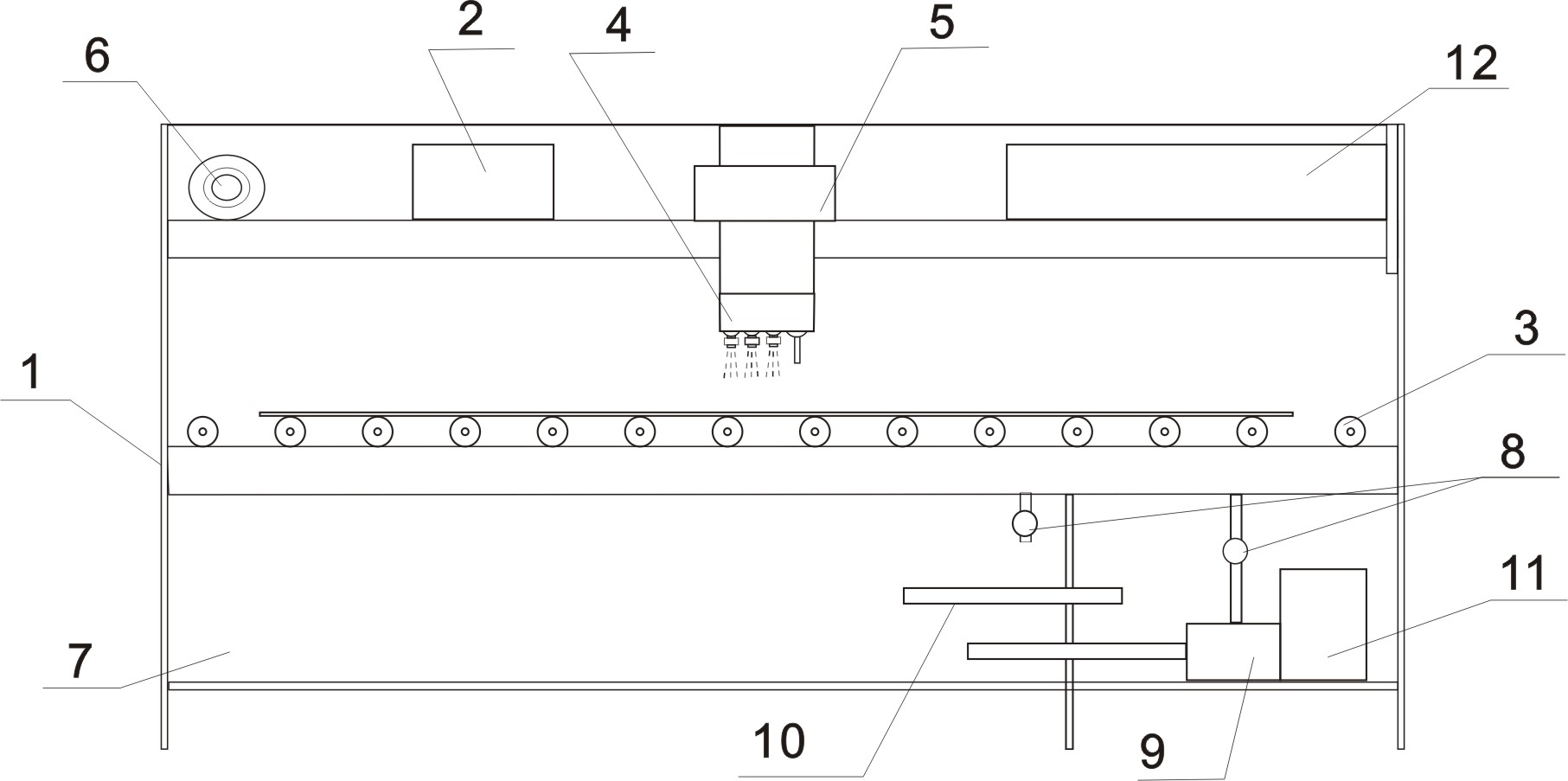

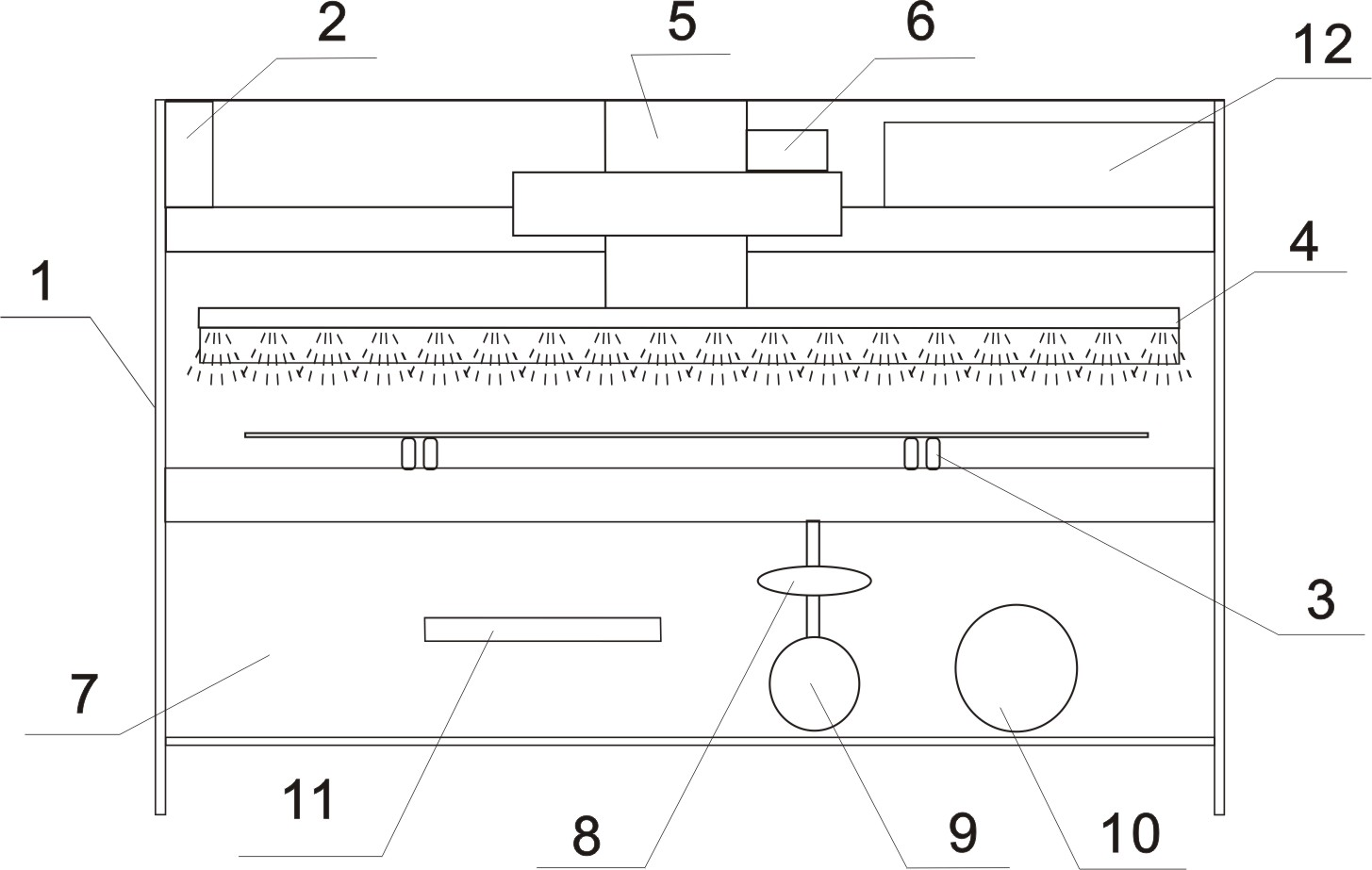

[0009] See ( figure 1 )( figure 2 )

[0010] The equipment box (1) of the large ultra-wide-format metal pattern etching machine is a hollow structure with upper, middle and lower layers. The upper part of the equipment box (1) is equipped with a moving machine (5) driving motor (6) and an automatic control box (12). The combined spray bar (4) extending to the middle is also fixed on the moving machine (5), and the upper drive motor (6) drives the mobile spraying rod fixed on it through the control of the automatic control box (12) of the moving machine (5). Bar (4) is done longitudinal reciprocating mechanical movement, and the lifting door and window part (2) of top realizes opening and closing door and window function by automatic control box (12). The workpiece supporting wheel (3) is installed in the middle of the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com