Waste bag and production method thereof

A technology of garbage bags and bag bodies, applied in the field of garbage bags and their production, can solve the problems of overflowing on the floor, spilling on the way of discarding garbage, contaminating the trash can, embarrassing, etc., and achieving great practicability and convenience. , The effect of protecting the indoor environment and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are to further illustrate the present invention, but not to limit the scope of the present invention.

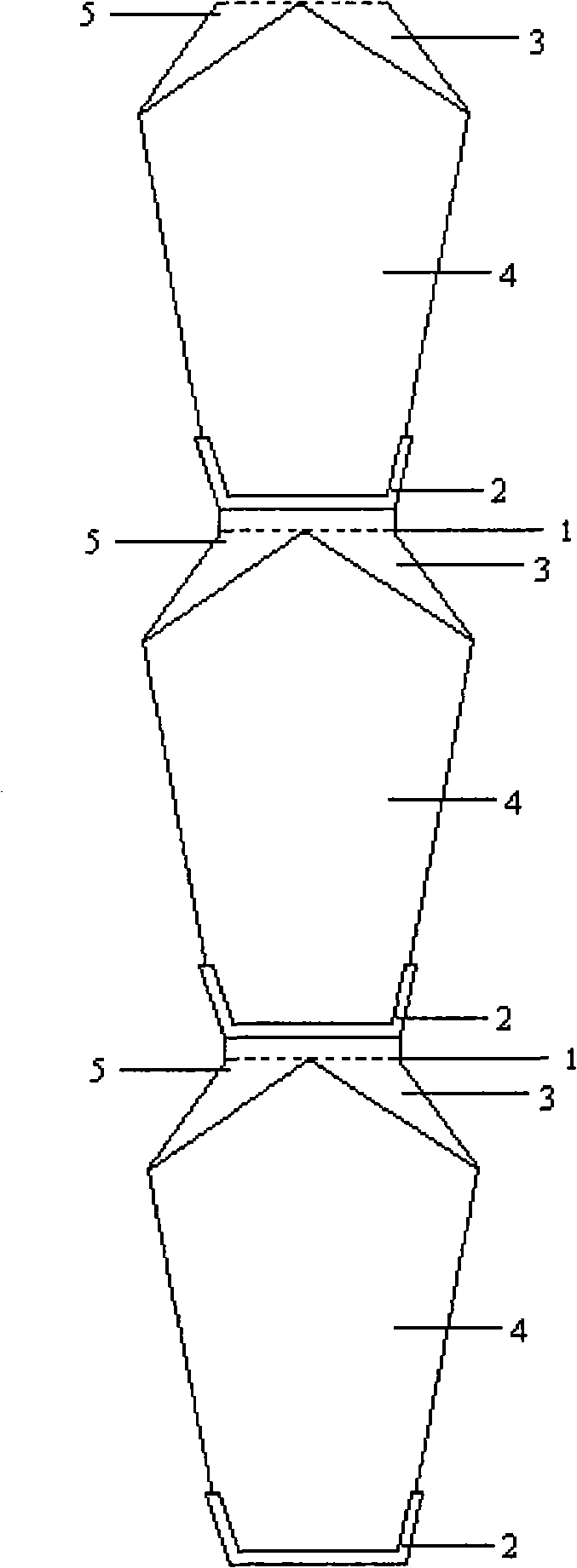

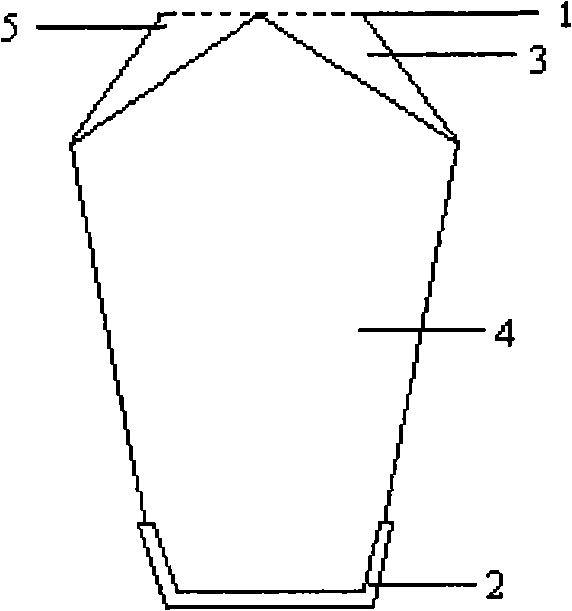

[0018] see Figure 1-Figure 3 , the present invention has developed a thickened disc-shaped bottom environmental protection conjoined garbage bag, which takes the following steps:

[0019] The environmentally friendly conjoined garbage bag is composed of a thickened fixing part 2 and a bag body 4. The thickened fixing part 2 is arranged under the bag body 4. The radius of the thickened fixing part 2 is smaller than the radius of the bag opening 5, and the whole is in the shape of an inverted frustum of a cone. The pocket opening 5 forms a triangular crease 3, and the width of the pocket opening 5 after the crease is the same as that of the thickened fixing piece 2. connect.

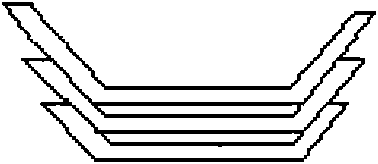

[0020] The thickened fixing part 2 is made of paper material or degradable material, double-sided laying and bonding of conventional plastics, and forms a fixed dish shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com