Equipment for testing pins of electronic element products automatically

An automatic detection and electronic component technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of manual intervention, error-prone, quality problems, etc., to save resources and management costs, high production efficiency, reduce the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

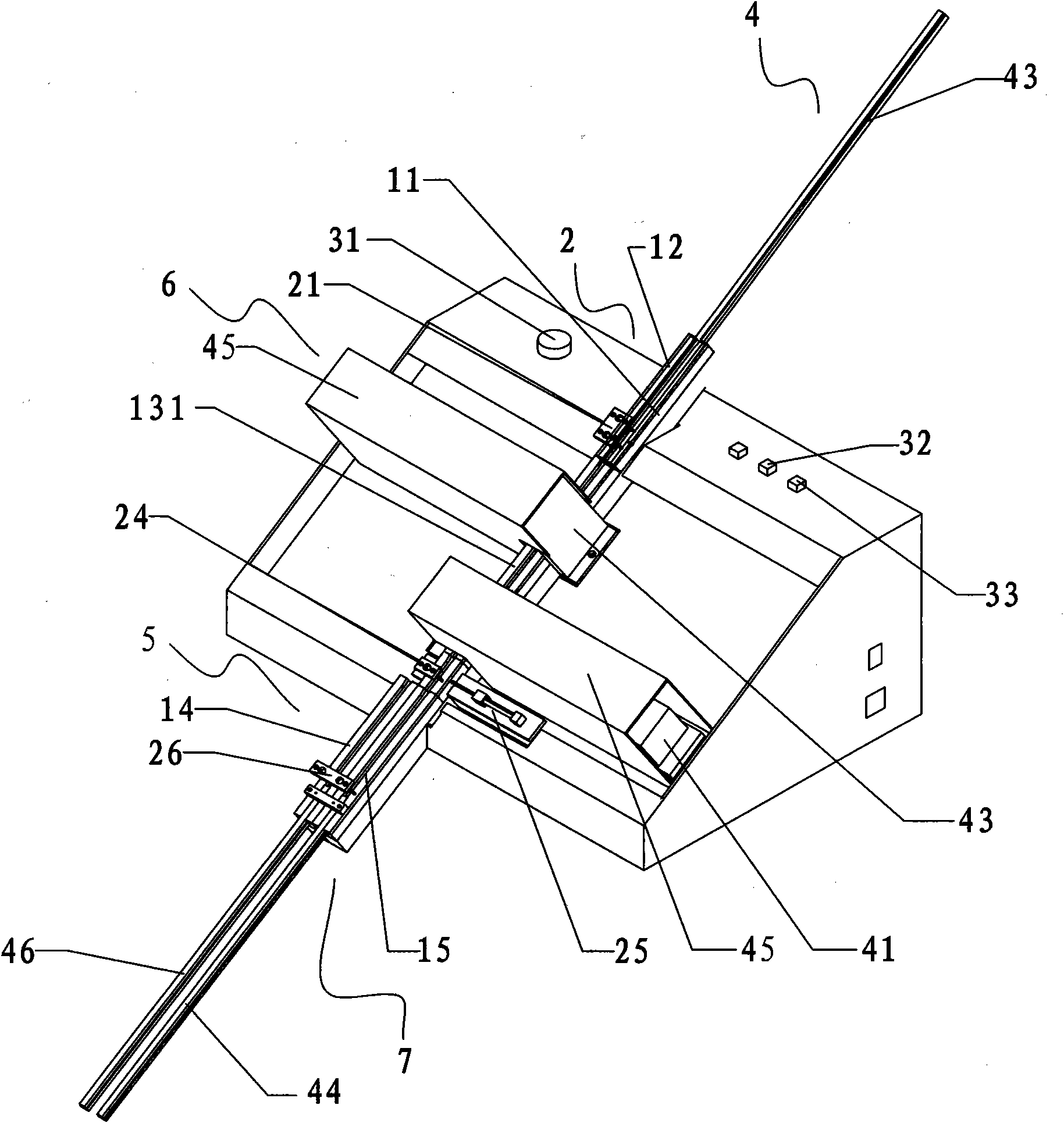

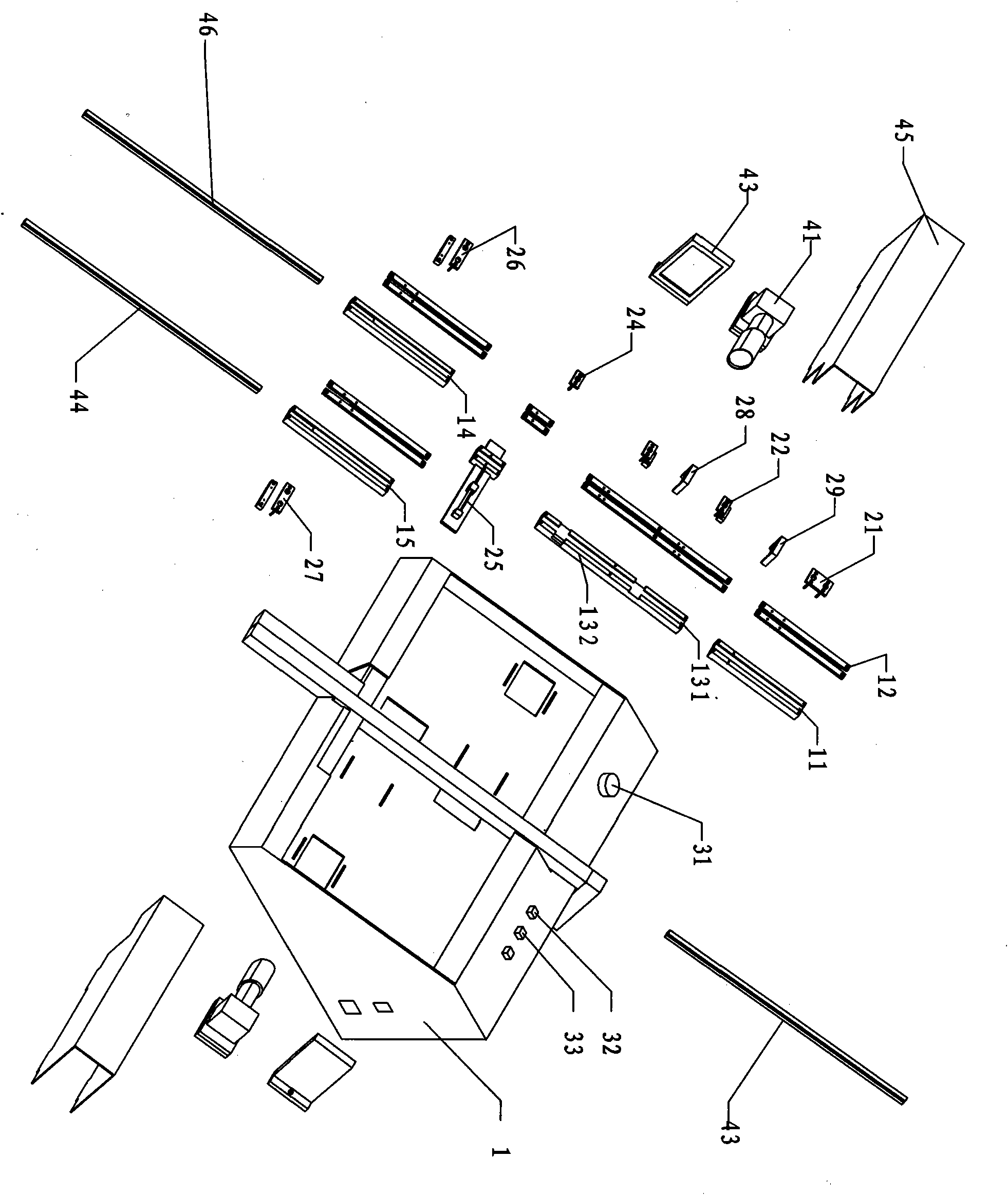

Method used

Image

Examples

Embodiment 2

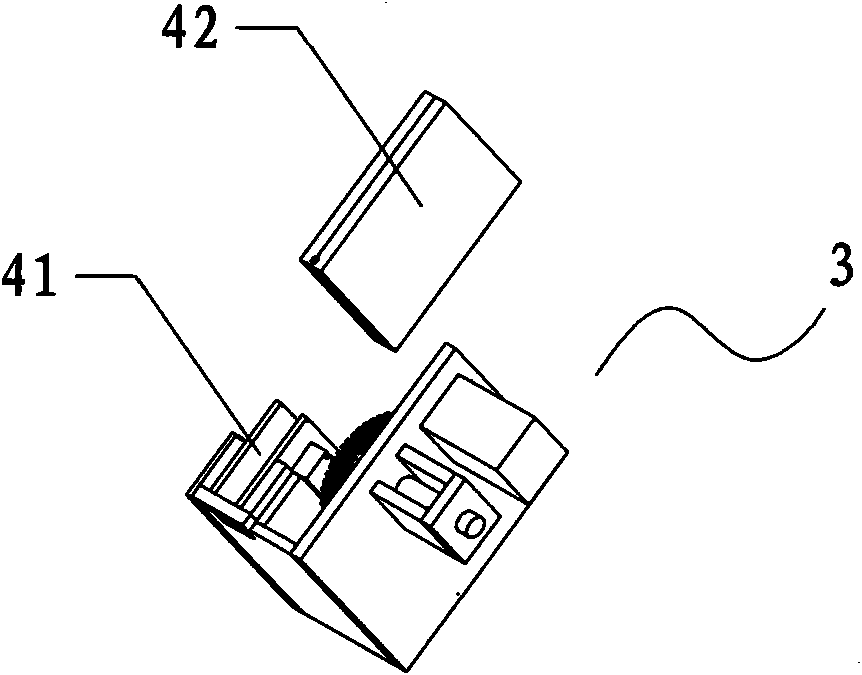

[0051] The difference between embodiment 2 of the present invention and embodiment 1 is the structure of its feeding device, and the specific structure of the feeding device of present embodiment 2 is: as image 3 As shown, the feeding device is a magazine device 3, and the magazine device is a magazine base 41 and a magazine 42 installed in the magazine base, the magazine top is inserted with a material pipe 43 for conveying electronic component products, and the magazine The lower part is connected to the detection slideway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com