Two-way beam multi-axis force sensor

A multi-axis force sensor and sensor technology, used in instruments, measuring forces, measuring devices, etc., can solve problems such as complex structure and measurement error, and achieve the effect of improving anti-eccentric load capacity, increasing external outline size, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

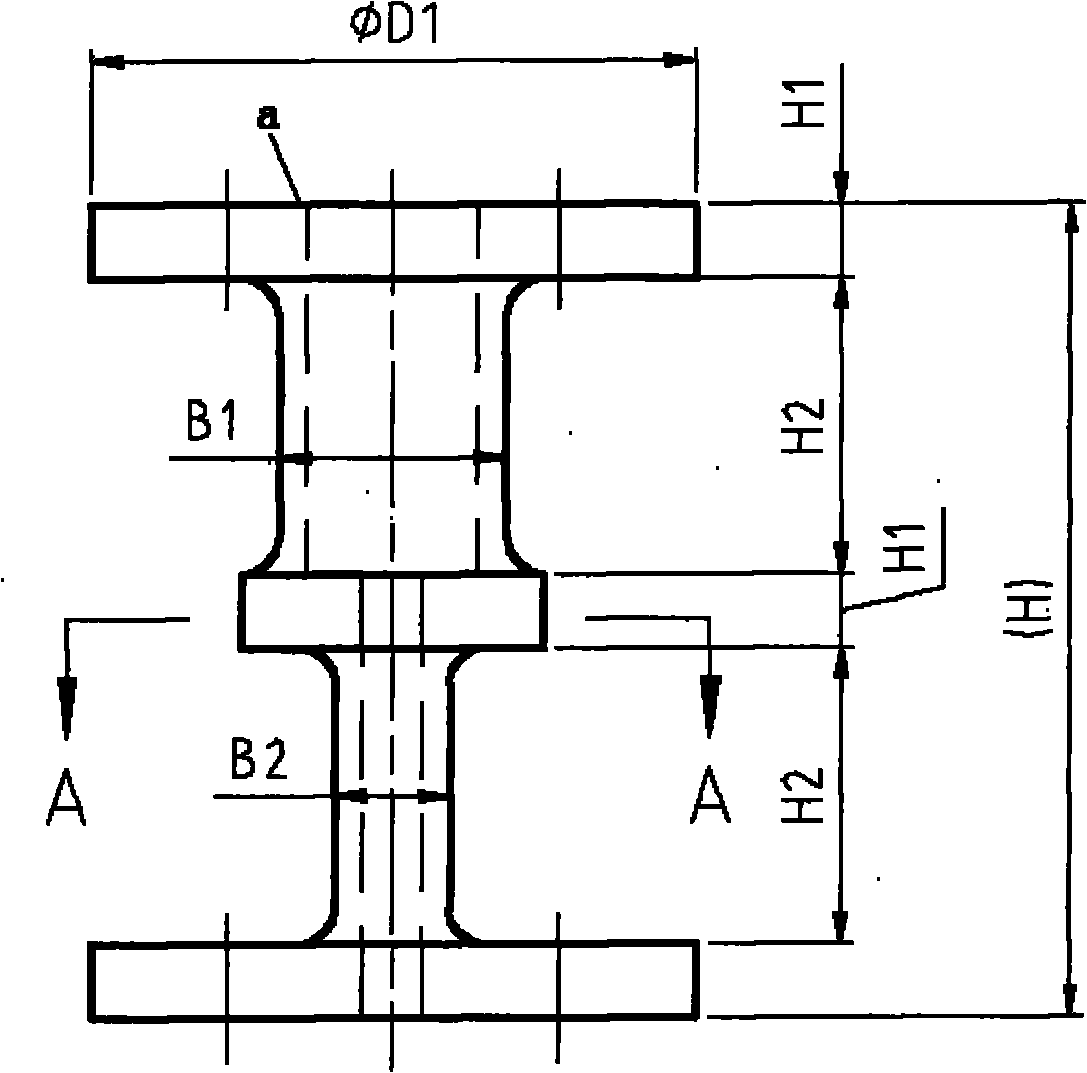

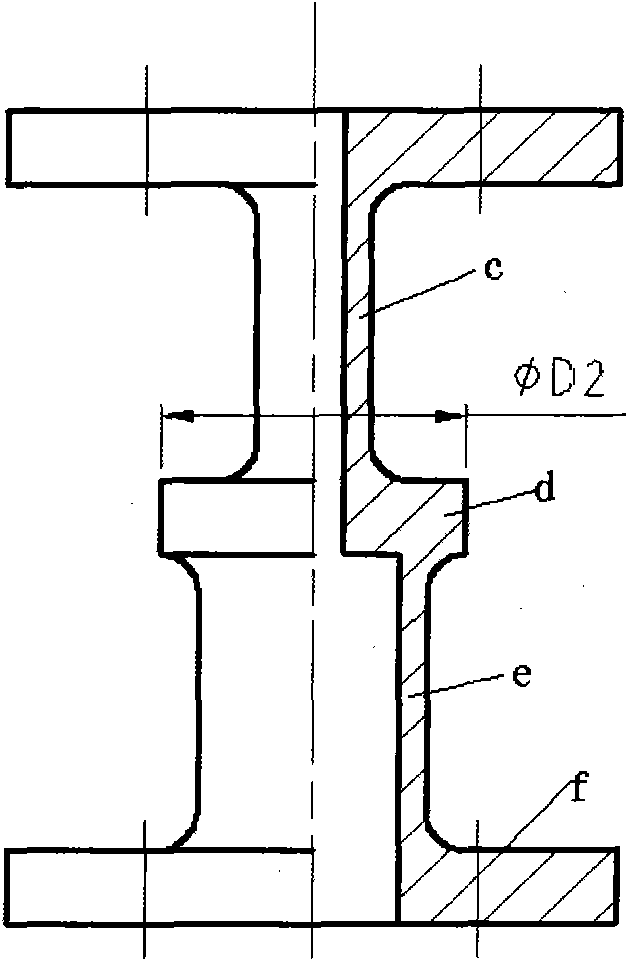

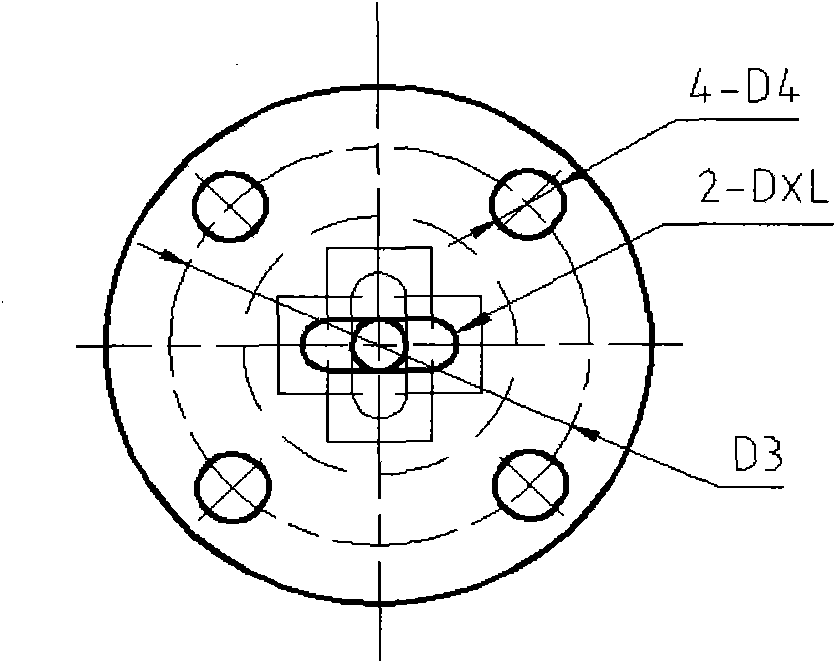

[0025] The structure and characteristics of the bidirectional weighing beam type multi-axis force sensor of the present invention:

[0026] The design of the sensor is to use the symmetrical beam structure as the elastic element of the sensor, and paste the resistance strain gauge on the corresponding section position to complete the measurement of three forces (X, Y, Z axis) and one torque (around the Z axis). The structure adopts the form of two-way symmetrical beams, which ideally improves the anti-load section coefficient of the other axial directions under the action of the main shaft load, greatly improves the anti-bias load ability of the sensor and the anti-interference ability during measurement, and makes the structure of the sensor more compact. The sensor has an integrated multi-section structure, which eliminates the measurement errors cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com