Improved particle swarm optimization method based on streamline production scheduling of fuzzy due date

A technology of pipeline production and optimization method, applied in the field of improved particle swarm optimization algorithm, which can solve the problem of particle swarm optimization algorithm falling into local extremum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

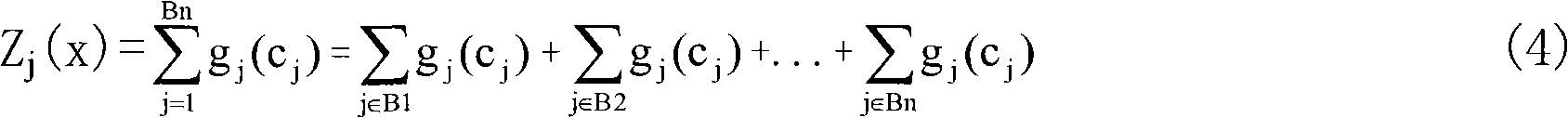

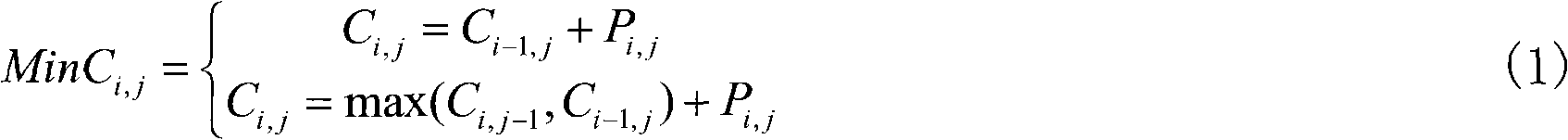

[0050] An improved particle swarm optimization method based on production scheduling, comprising the following steps:

[0051] Step 1. Encode the particles.

[0052] represents a solution to the shop-shop scheduling problem, where n represents the dimensionality of the particles in the particle swarm, Indicates the position value of the i-th particle in the k-th generation in evolution, if Indicates that the particle i (workpiece) of the kth generation is not processed on the jth machine, if Indicates that the k-th generation particle i (workpiece) is processed on the j-th machine; Indicates the speed of the i-th particle when it evolves to the k-th generation, k is the number of iterations; the best position experienced by the individual particle is recorded as P best , the best position experienced by the whole group of particles is denoted as G best .

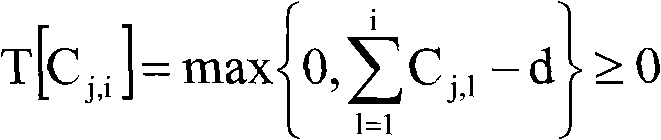

[0053] Step 2. Determine the objective function for the completion period of the artifact.

[0054] In the F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com