Novel energy-saving vacuum oven

A technology of vacuum oven and oven, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, non-aqueous electrolyte storage battery, etc. It can solve the problems of uneven temperature difference, large heat loss, and uneven heat transfer in the working box 1. Achieve the effects of reducing heat transfer links, improving heat utilization, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

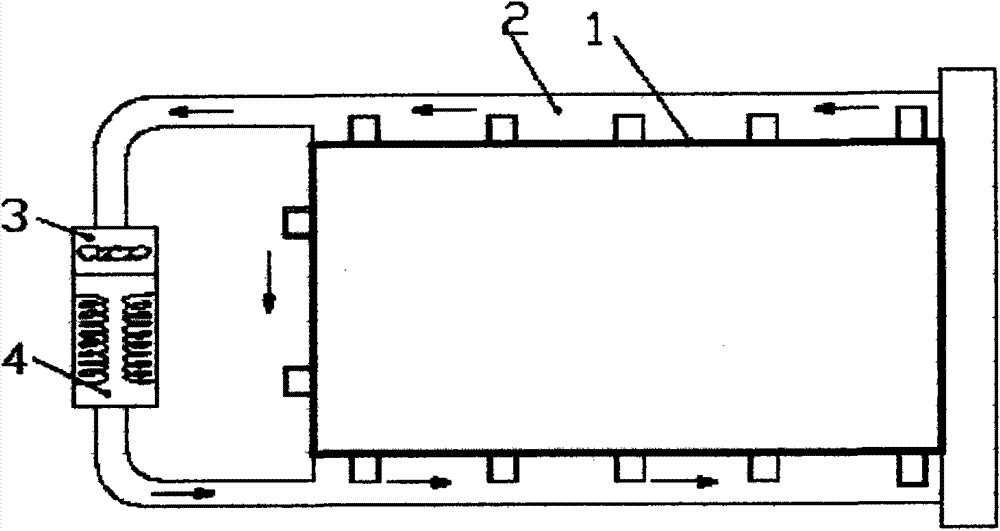

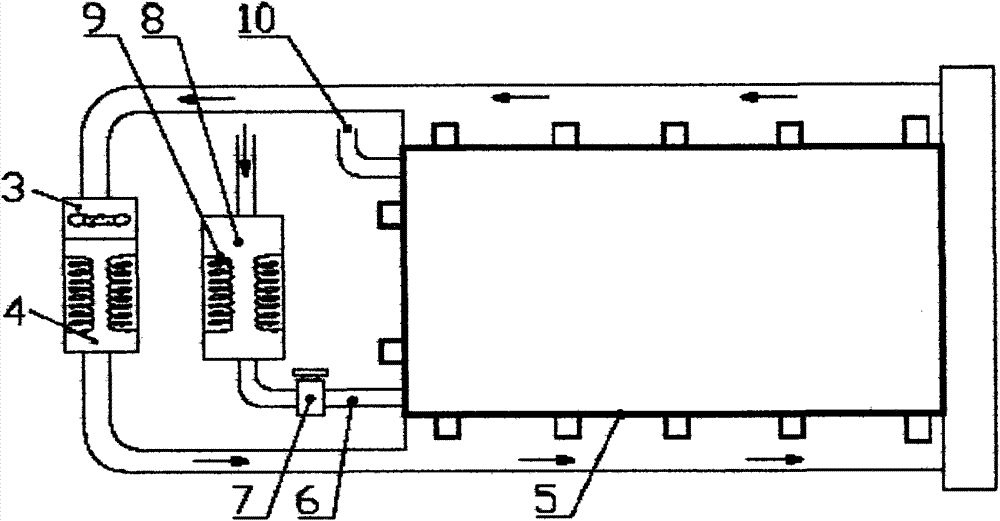

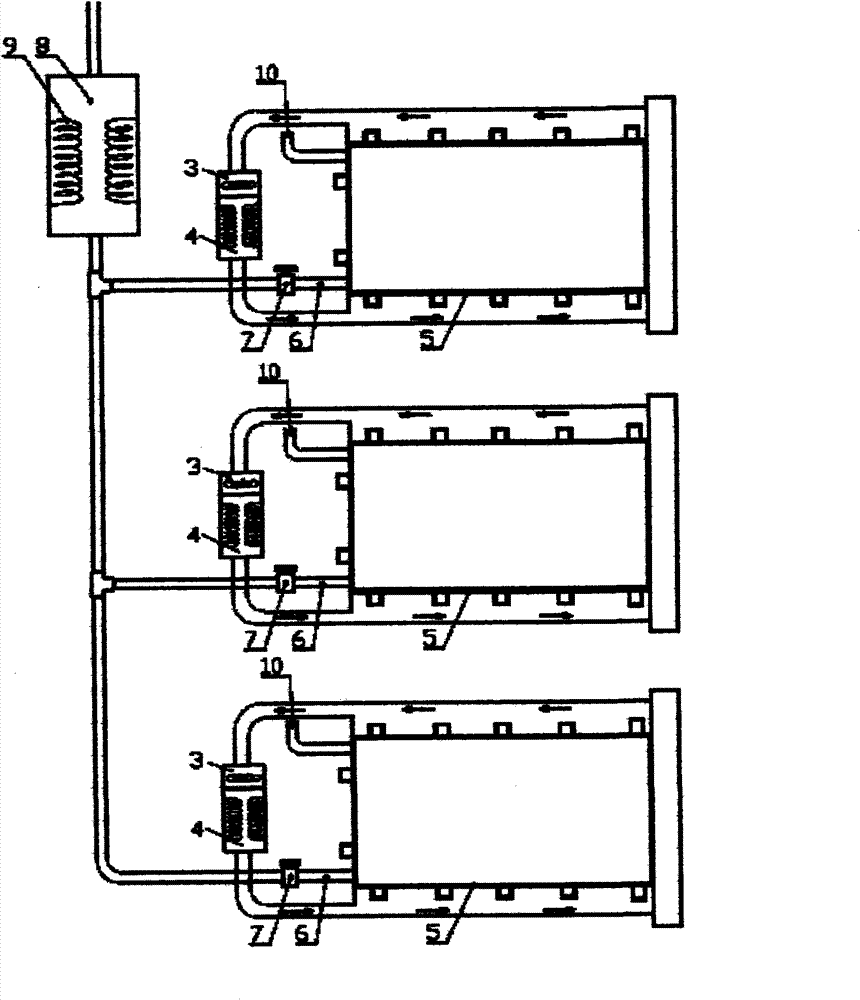

[0021] Please refer to figure 2 As shown, a specific implementation of the new energy-saving vacuum oven, its structure includes a working box 5 installed inside the main body of the oven, and one end outside the working box is provided with a constant temperature adjustment and equalization device. A peripheral hot air circulation channel is arranged on the periphery of the working box, and a thermal power source 3 and a heat source 4 are arranged in the peripheral hot air circulating channel. The constant temperature adjustment and balancing device includes a vacuum pipeline 6 connected with the working box A control valve 7 on the vacuum pipeline 6 for controlling the flow rate of the transfer medium, and a thermostatic regulating box installed on the vacuum pipeline 6 at the input end of the control valve 7 . The constant temperature adjustment and equalization device can be used for heating the transfer medium, and in addition, the constant temperature adjustment and equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com