Self-driven mower

A lawn mower and self-propelled technology, used in harvesters, motors, cutters, etc., can solve problems such as battery damage, and achieve the effects of extending service life, improving comfort, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

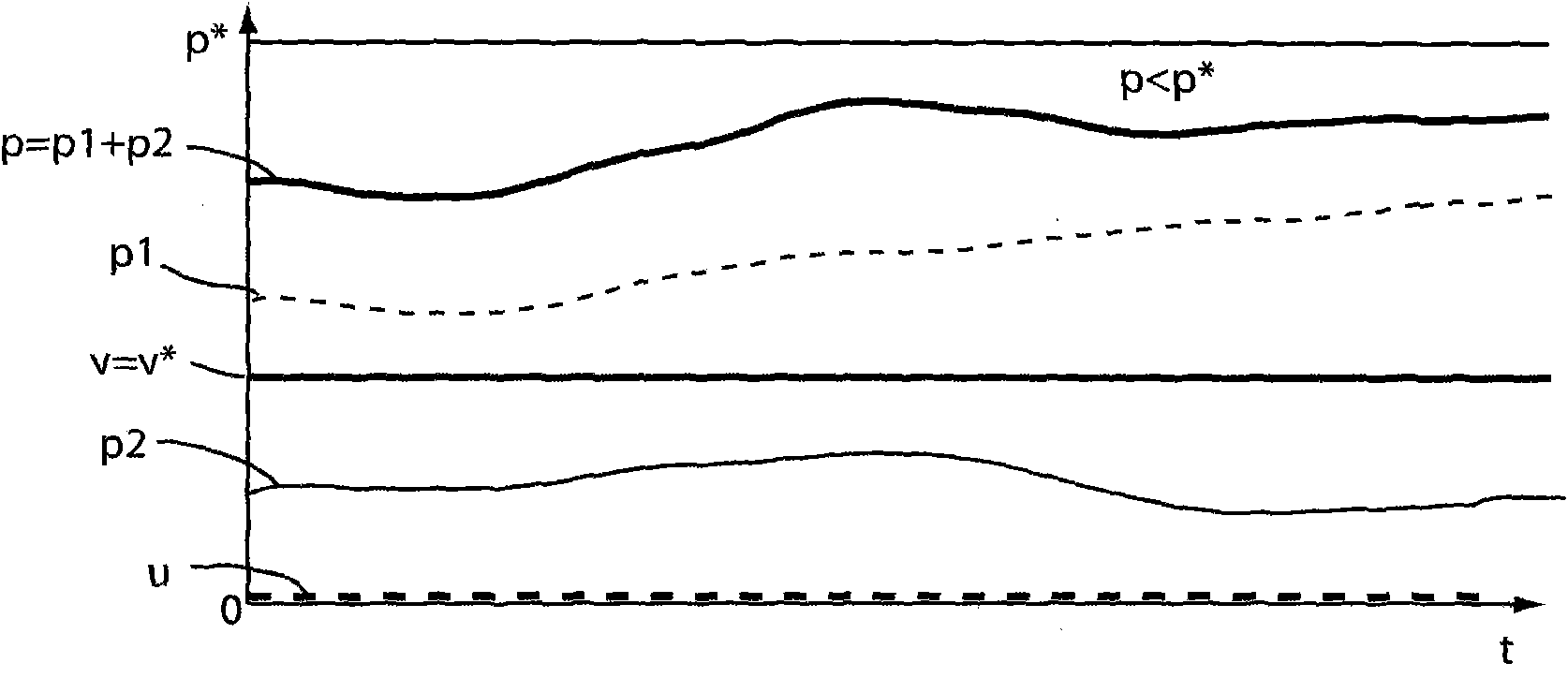

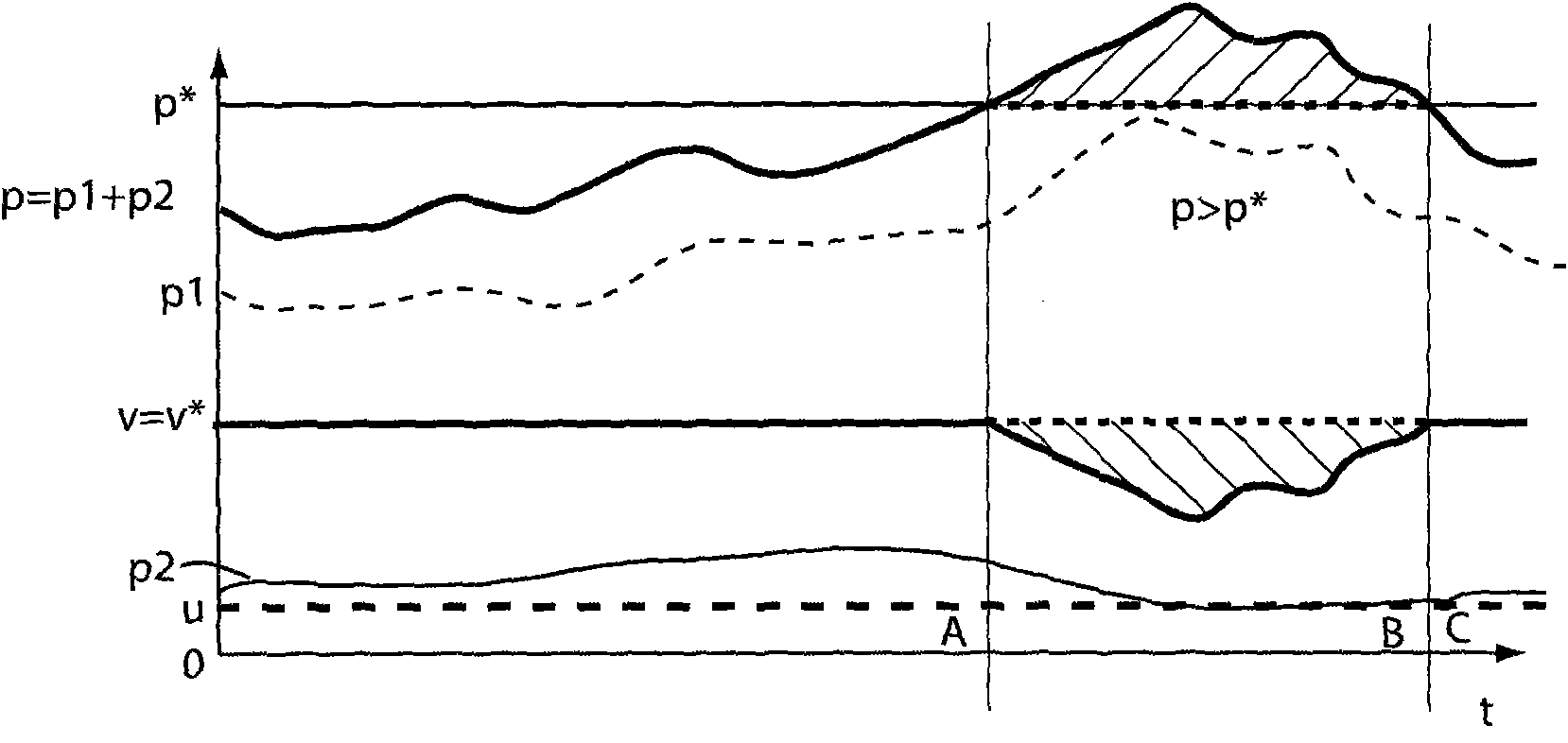

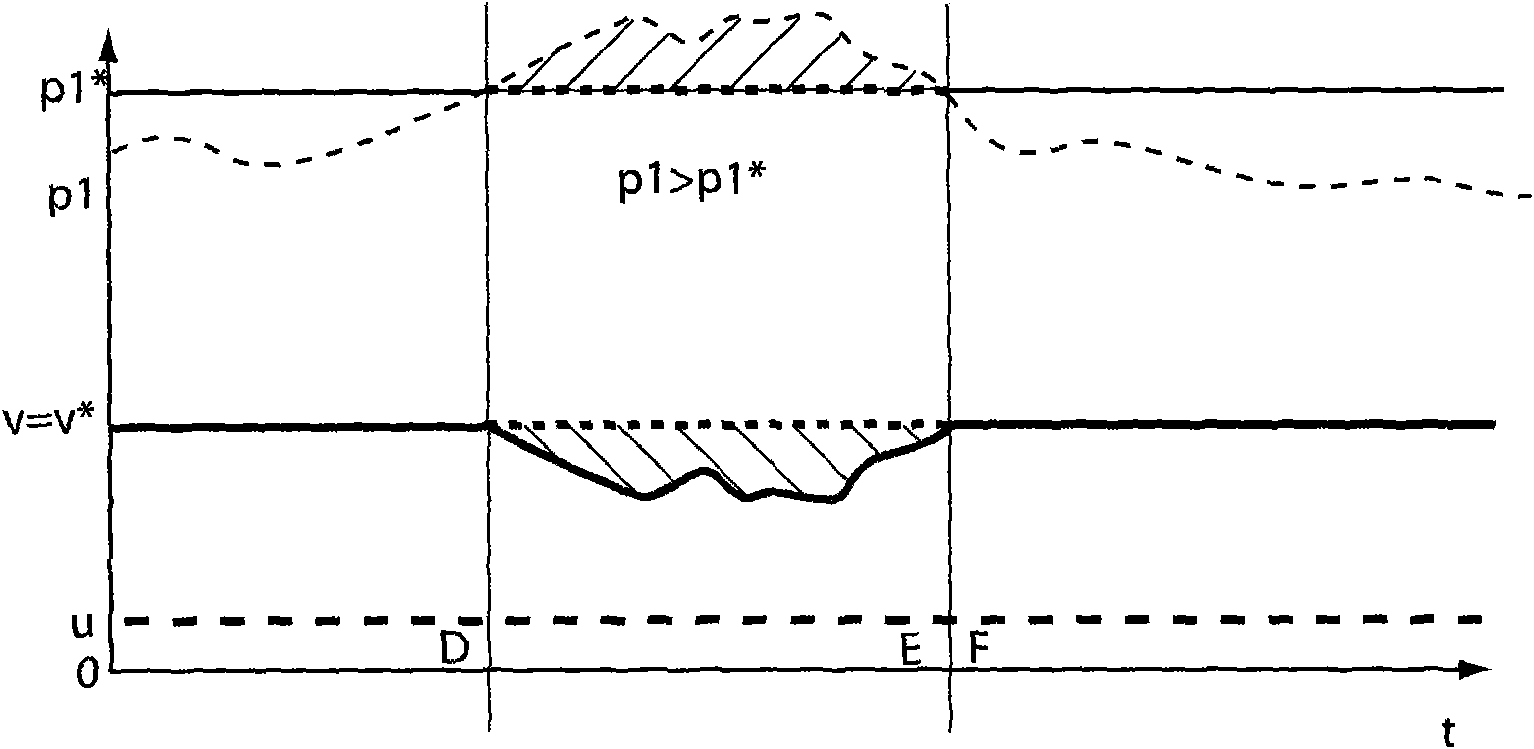

[0087] figure 1 with figure 2 The driving schematic diagram of the electric lawn mower of the present invention changing with time t is disclosed. Except for the control unit, the lawn mower of the present invention has a traditional structure and includes an electric blade motor for rotating and driving the cutting blades. The blade motor is operatively connected to a battery; used to drive the lawn mower along the lawn that needs to be trimmed The electric drive motor is operatively connected to the battery. Reference Figure 4 to Figure 7 As will be described, the present invention provides a control unit and associated components for controlling the movement of the lawn mower through the blade motor and the driving motor. Preferably, the electric drive motor acts on at least one rear wheel.

[0088] In order to more easily explain the purpose of the present invention, in figure 1 In, it is set that the operator does not push the lawnmower, so the operator does not perform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com