Automatic cleaning device of rotary screen for producing compound fertilizer

An automatic cleaning and trommel screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of screen wear and cleaning, which can reduce production costs, achieve good screening and cleaning effects, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

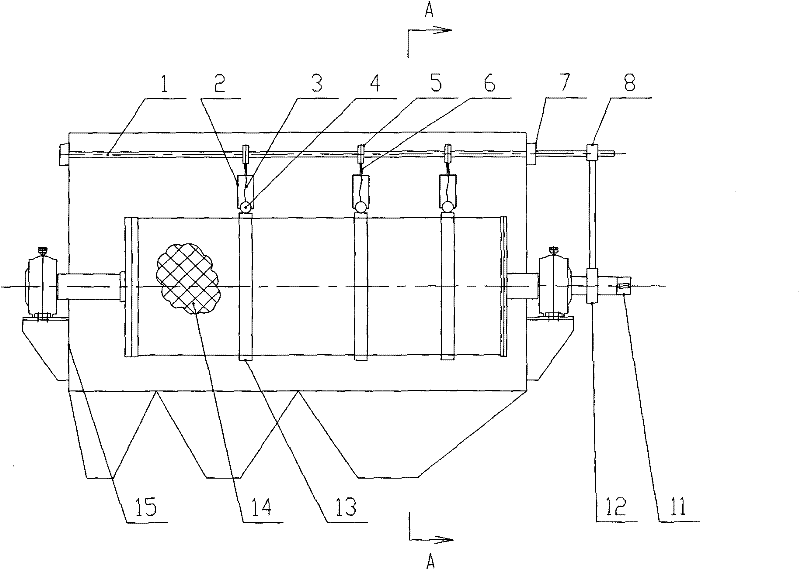

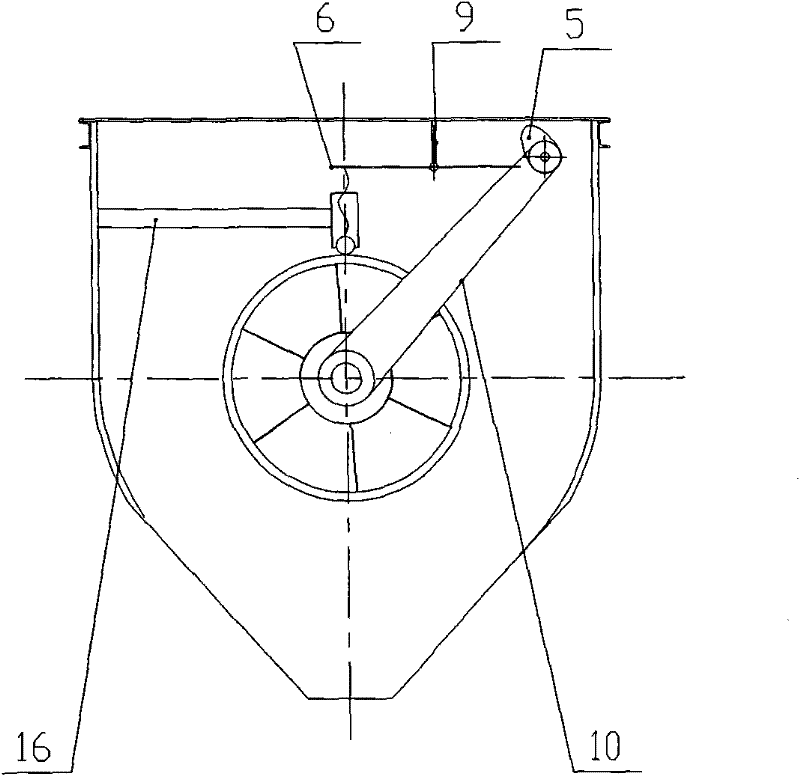

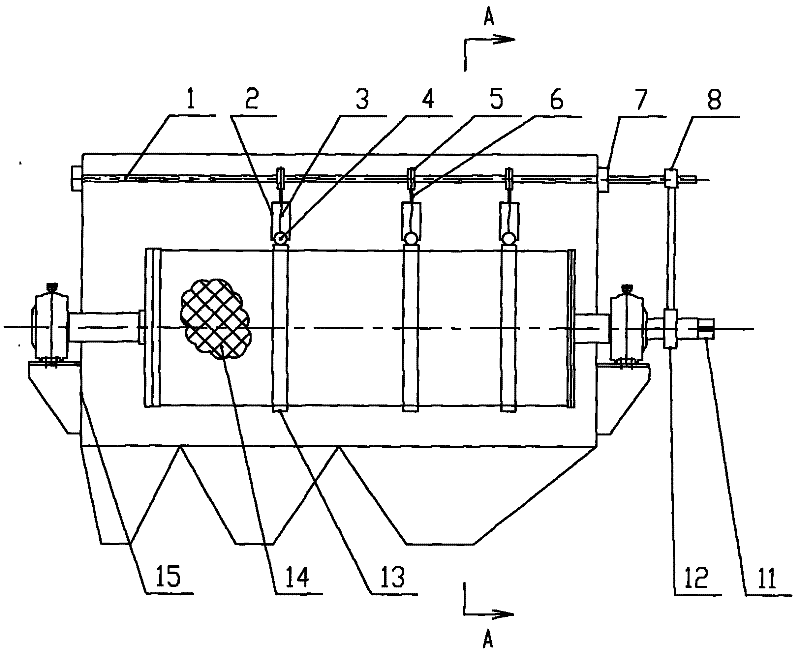

[0031] A kind of drum screen automatic cleaning device for producing compound fertilizer, such as figure 1 , 2 As shown, it includes a transmission device and a rapping device. The connection relationship of the transmission device is: the driving sprocket 12 fixed on the drum screen main shaft 11 is connected with the transmission sprocket 8 installed on the rapping main shaft 1 through a transmission chain 10 .

[0032] The connection relationship of the rapping device is: the rapping main shaft 1 is installed on the drum screen housing 15 through the bearing device 7, and the rapping main shaft 1 is equipped with a cam 5, and the cam 5 corresponds to the fixed ring 13. The rib plate 16 welded to the screen housing 15 fixes the guide cylinder 2 directly above the apex of the fixed ring 13, the rapping ball 4 is connected to the lever 6 through a soft connection 3, and placed in the guide cylinder 2, the lever 6 is welded to the roller screen The guiding fulcrums 9 on the h...

Embodiment 2

[0034] An automatic drum screen cleaning device for compound fertilizer production, the structure can still refer to figure 1 , 2 , but the difference from Example 1 is that the fixed rings 13 are distributed axially on the drum screen with a distance of 1 meter. Of course, the spacing can also be extended to 1.5 meters.

Embodiment 3

[0036] An automatic drum screen cleaning device for compound fertilizer production, the structure can still refer to figure 1 , 2 , but the difference from Embodiment 1 is that the eccentric parts of the cam 5 are evenly distributed in the circumferential direction centered on the rapping main shaft 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com