Wiper blades for windshield wipers

A technology of wiper blades and wipers, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems of inability to generate uniform welded connections, and achieve the effect of uniform welded connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

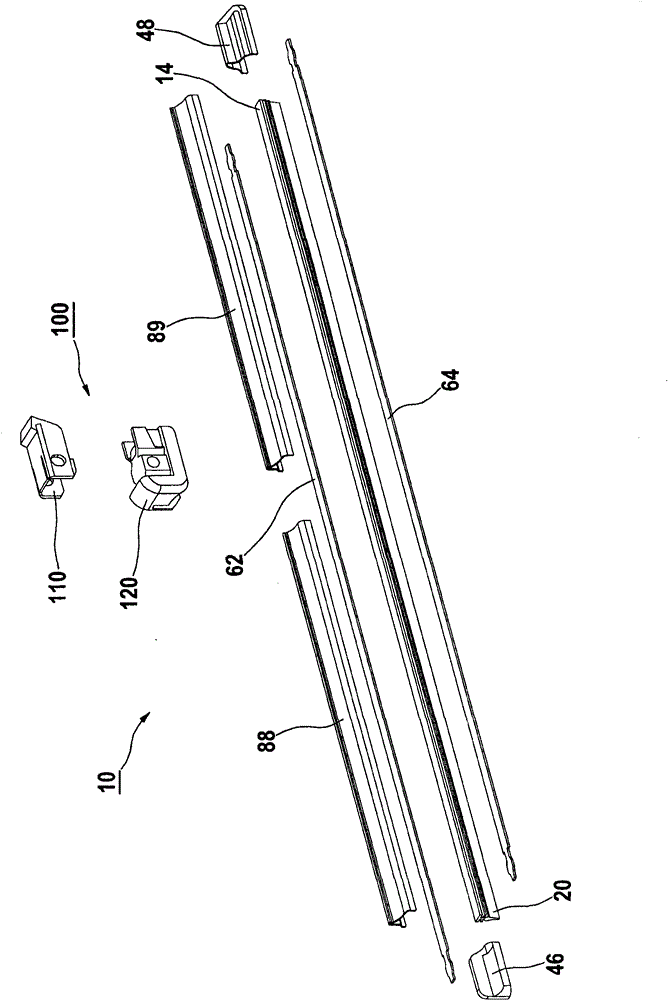

[0025] figure 1 A plurality of components are shown, which according to one embodiment form a wiper blade 10 , in particular for a windshield wiper for cleaning motor vehicle windows. According to one specific embodiment, the wiper blade 10 is designed as a flat beam.

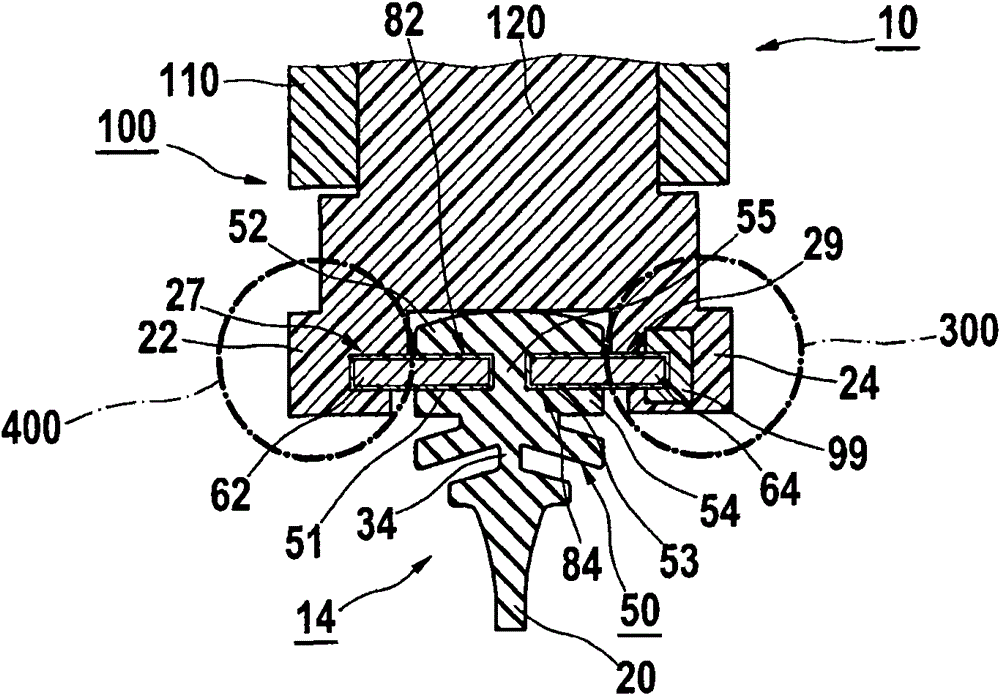

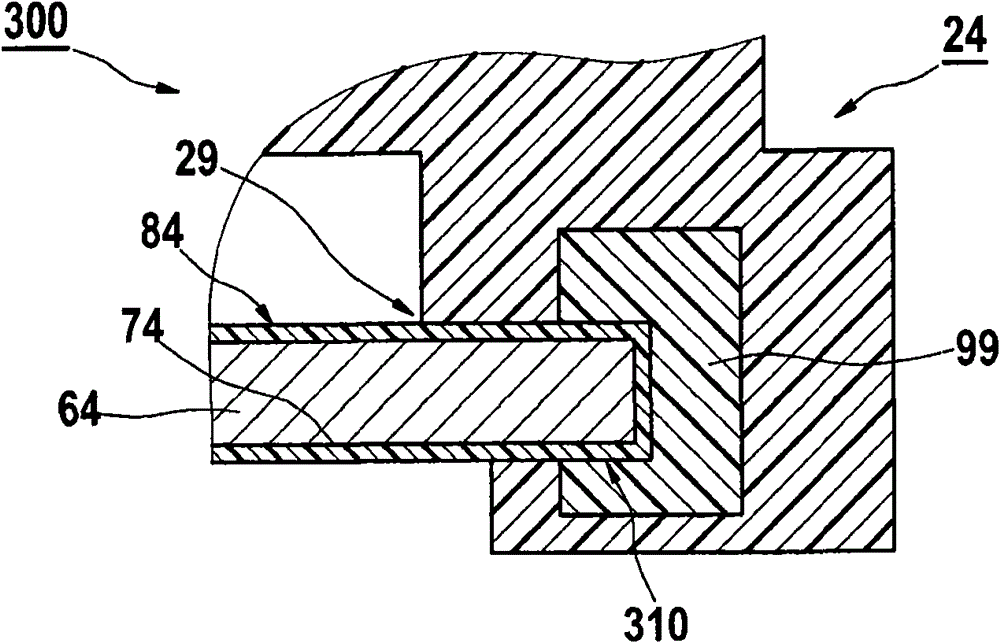

[0026] The wiper blade 10 has, for example, a two-part spoiler 88 , 89 , two end caps 46 , 48 , two support rails 62 , 64 and a wiper strip 14 with at least one wiper lip 20 . A connecting element 100 is provided for fastening the wiper blade 10 on an associated wiper arm, preferably according to the so-called side-lock or top-lock principle. The connecting element has, for example, a base adapter 120 and a fastening spring 110 . According to one specific embodiment, the base adapter 120 can be connected to the support rails 62 , 64 in a hingeless and permanent manner, as described below image 3 and 4 described in . Fastening spring 110 can be fastened to an associated wiper arm and can be articulatedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com