Rotating flexible shaft supporting tube formed by asymmetrically combing double-substrate type supporting blades

An asymmetric and support tube technology, applied in the direction of flexible shafts, shafts, shafts and bearings, can solve the problems of unsatisfactory improvement effects, achieve the effects of preventing rotation, simple replacement, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 Embodiment 2

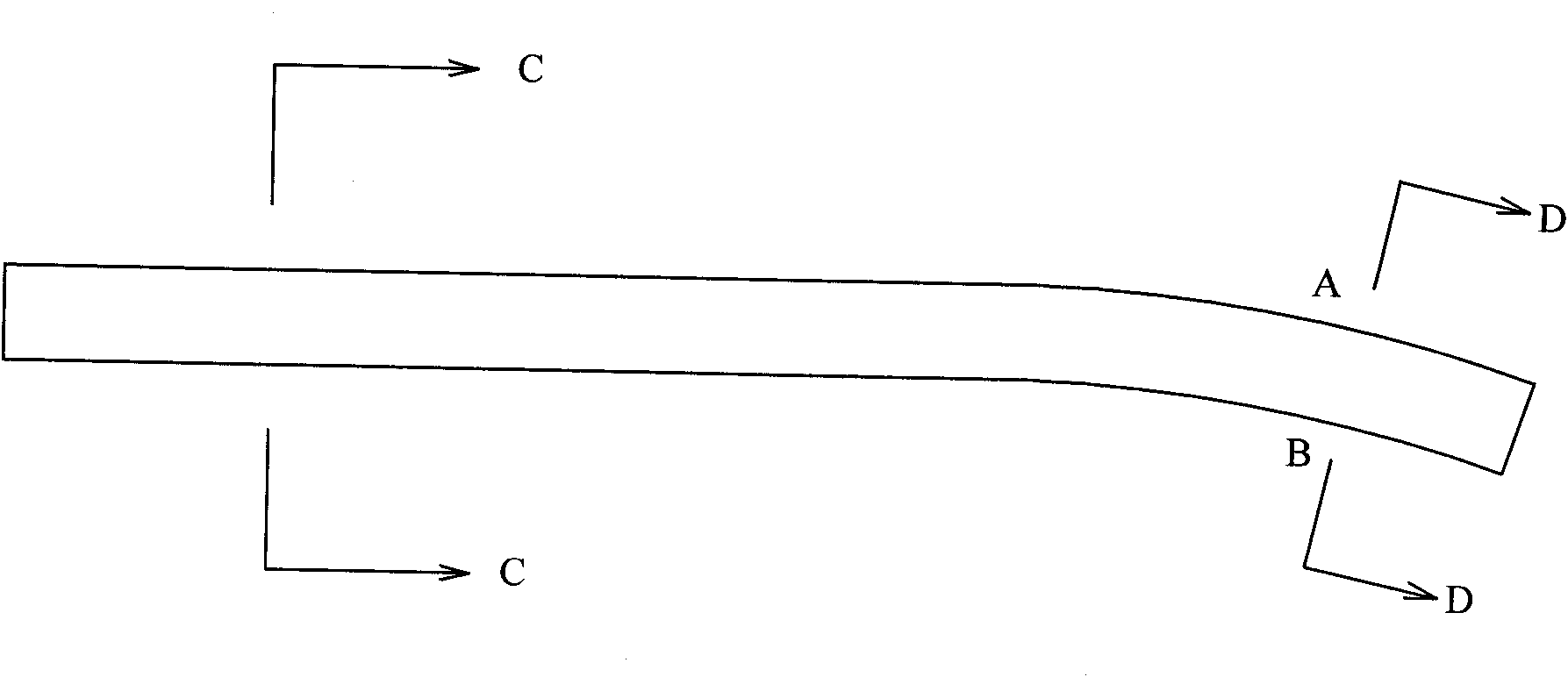

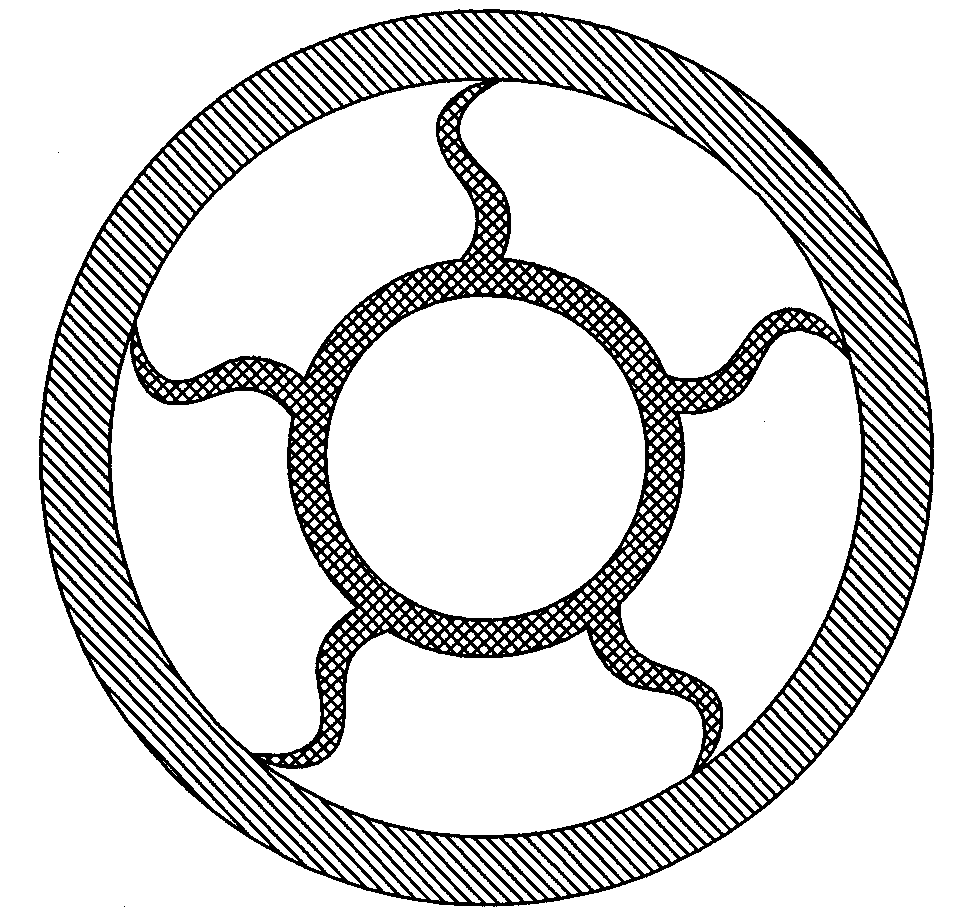

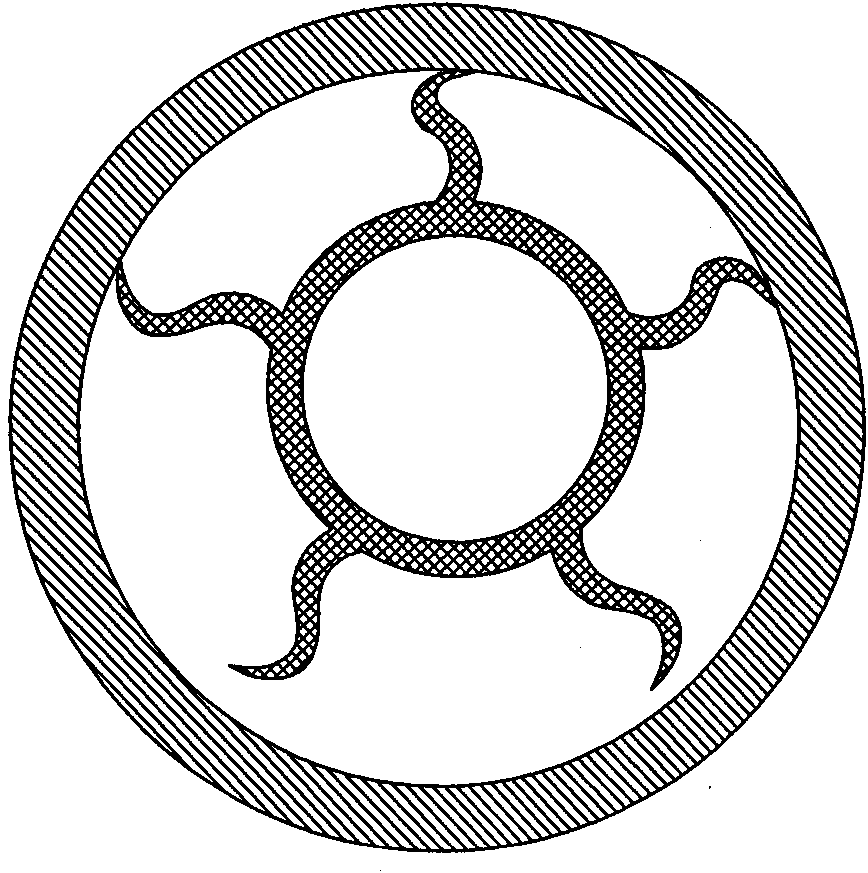

[0029] Embodiment 1, Embodiment 2: In the cross-section of the elastic support blade 3, the outer ring of the elastic support blade 3 is circular, and the thickness of the elastic support blade 3 is gradually reduced from the bottom end to the top end, and in On the cross-section of the inner tube body 1, the inner ring of each elastic support blade 3 intersects with the outer ring of the inner tube body 1 (such as Figure 4 ) or tangent (such as Figure 5 ).

Embodiment 3、 Embodiment 4

[0030] Embodiment 3, Embodiment 4: In the cross-section of the elastic support blade 3, the outer ring of the elastic support blade 3 is oval, and the thickness of the elastic support blade 3 is gradually reduced from the bottom end to the top end. On the cross-section of the inner tube body 1, the inner ring of each elastic support blade 3 intersects with the outer ring of the inner tube body 1 (such as Image 6 ) or tangent (such as Figure 7 ).

Embodiment 5

[0031] Embodiment 5: In the cross-section of the elastic support blade 3, the outer ring of the elastic support blade 3 is diamond-shaped, and the thickness of the elastic support blade 3 gradually decreases from the bottom end to the top end, and the inner tube body 1 On the section, the inner ring of each elastic support blade 3 intersects with the outer ring of the inner tube body 1 (as Figure 8 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com