Cooling bed driving shaft and manufacturing method thereof

A technology for drive shafts and cooling beds, which is applied in the manufacture of tools, eccentric shafts, welding equipment, etc. It can solve the problems of drive shaft clamping, alignment difficulties, different crank deflection angles, and difficulty in securing crank holes, etc., to save manpower and material resources and processing time, increased welding difficulty, and reduced machining difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

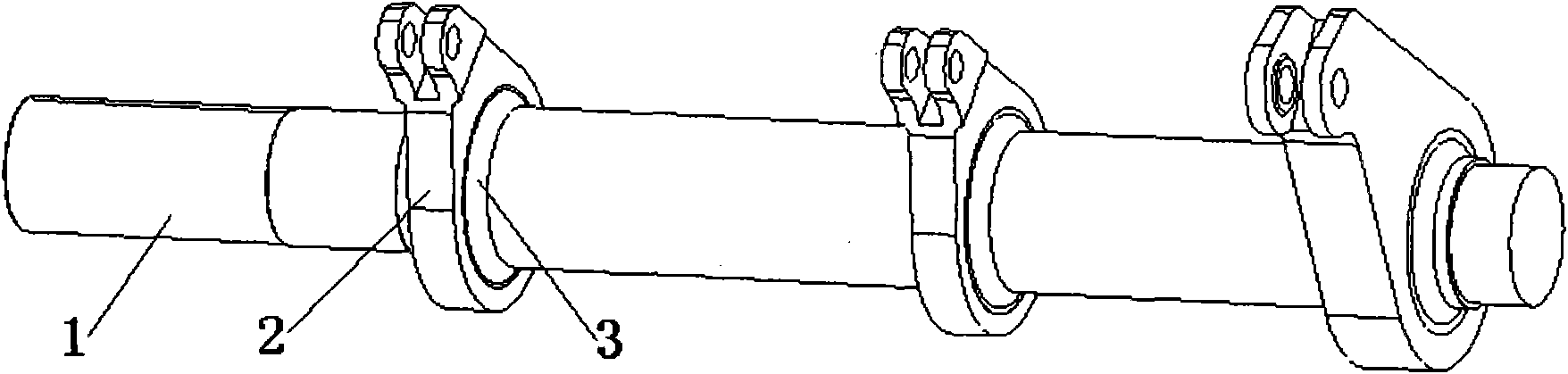

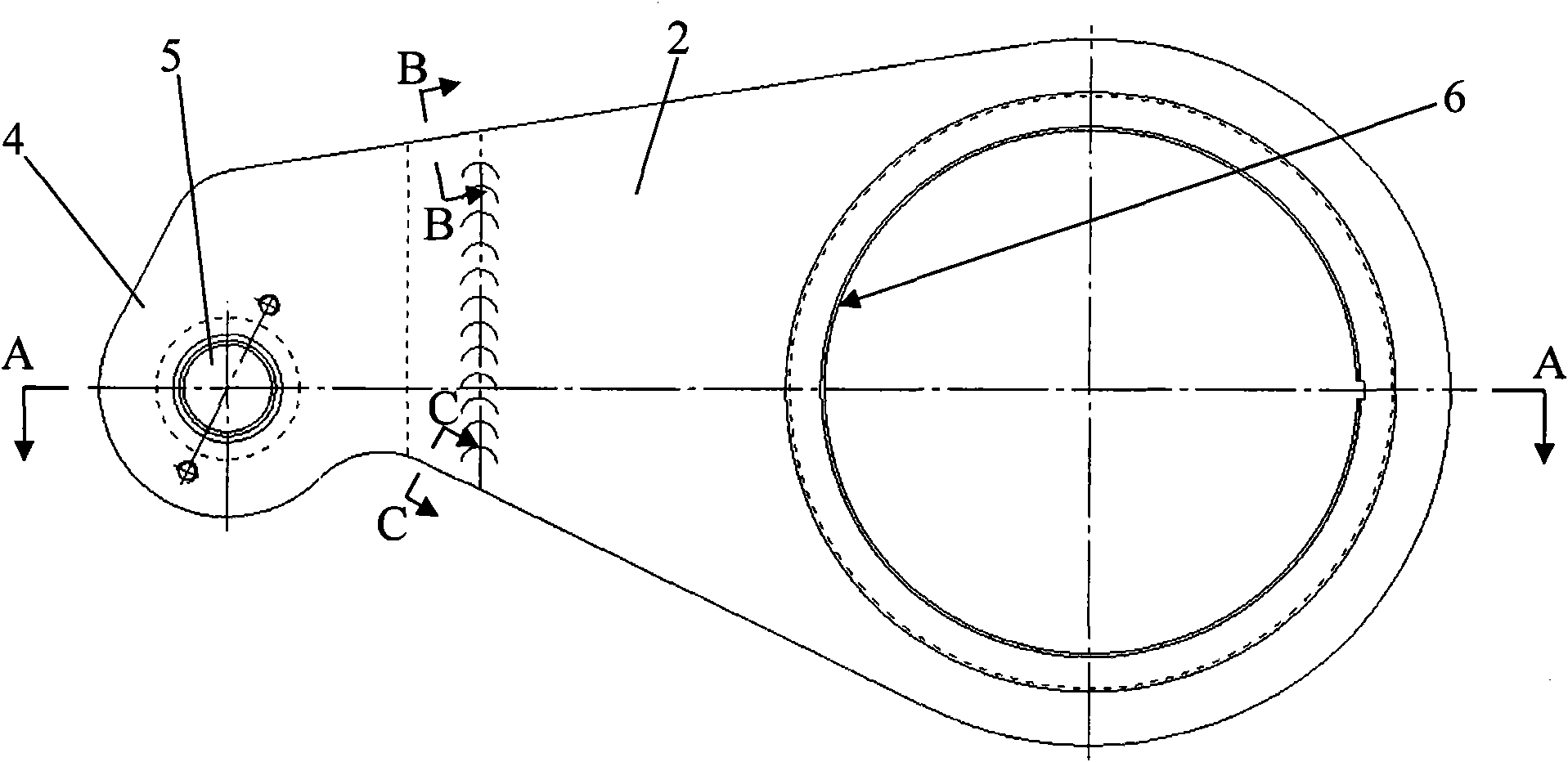

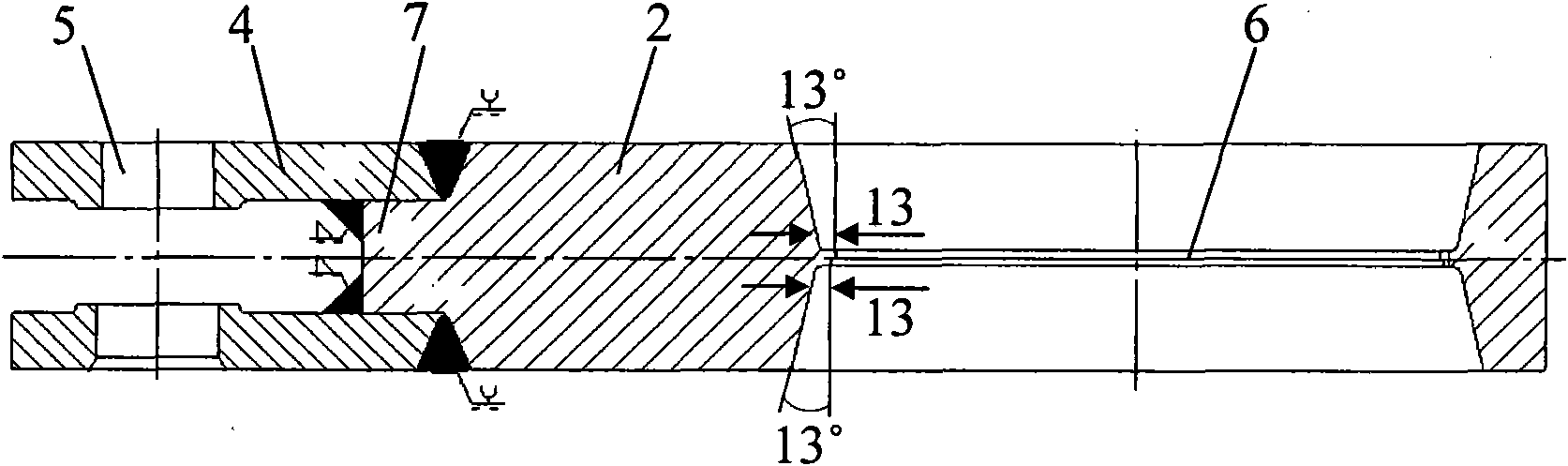

[0027] see Figure 1 to Figure 6 , Shaft 1 is shaped on three pillow blocks 3, each pillow block is welded with a crank 2 with a fork 4 on the head, and a connecting hole 5 is formed on the fork. The crank hole 6 and the pillow block are interference fit (H7 / p6), and the circumferential positioning key of the standard key fit (25JS9 / 25h8) is installed between the crank hole and the pillow block, and the axial positioning key is formed on the pillow block. Shaft shoulder, the fork of the crank is a splicing structure, the splicing structure is that the cross section of the splicing end 7 of the crank and the fork is convex, and the splicing ends of the crank and the fork are respectively shaped with welding grooves. The left and right mating ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap