Detection equipment of inner wall of opaque glass bottle

A technology for testing equipment and glass bottles, which is used in optical testing for flaws/defects, sorting, etc., to achieve the effects of high working accuracy, labor saving, and intelligent operation

Inactive Publication Date: 2010-10-20

CHANGSHA LIGHT IND MACHINERY

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem solved by the present invention is to provide a kind of detection equipment for the inner wall of opaque glass bottles, which adopts the principle of extending reflector and machine vision, and analyzes the collected images by computer, and automatically rejects the unqualified bottles, so as to solve the above-mentioned background technology. Disadvantages in

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

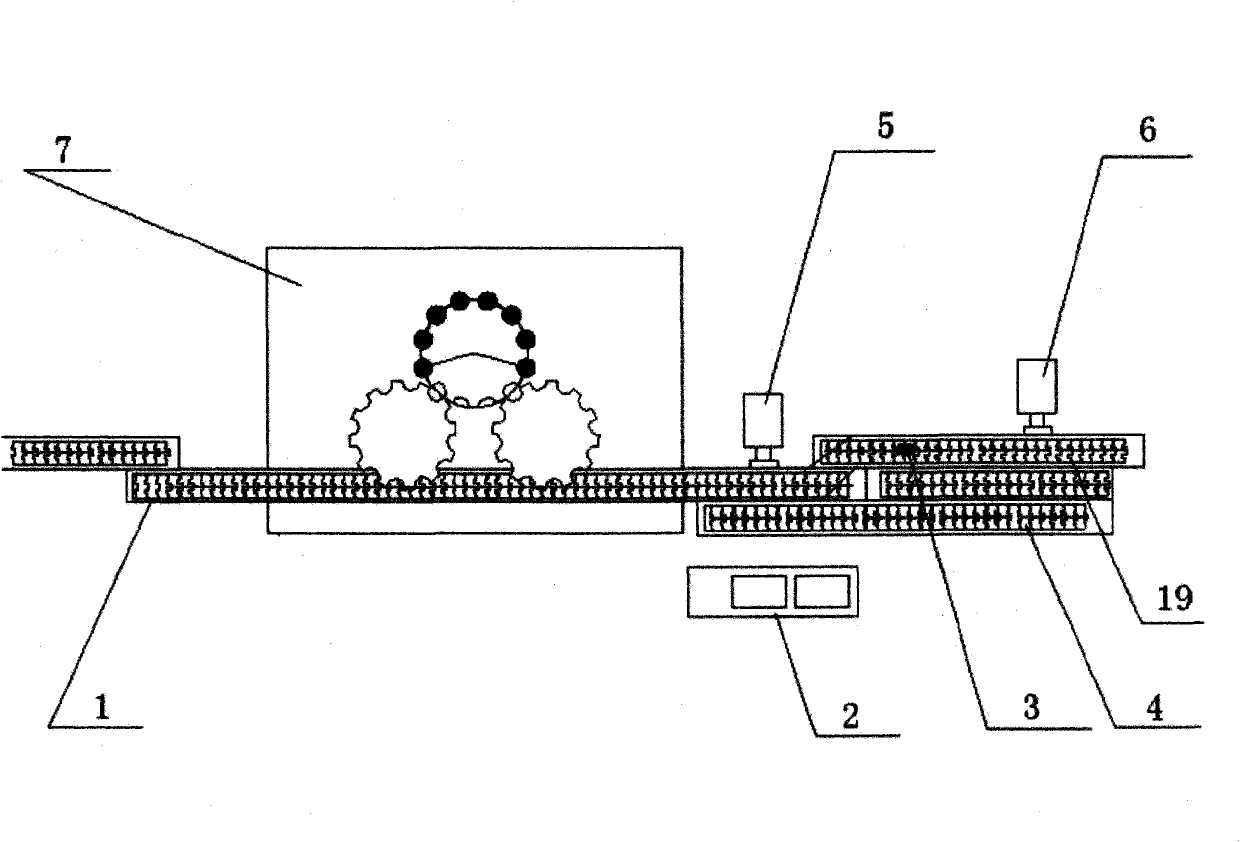

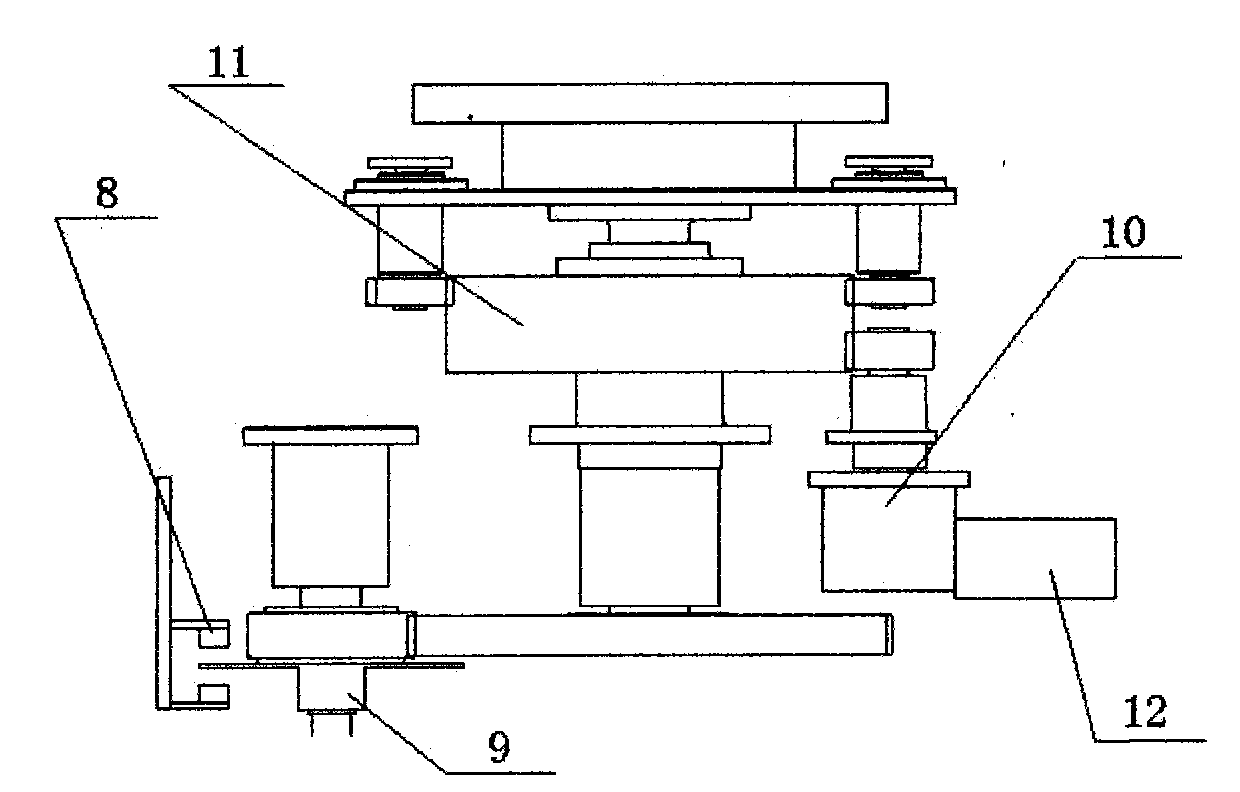

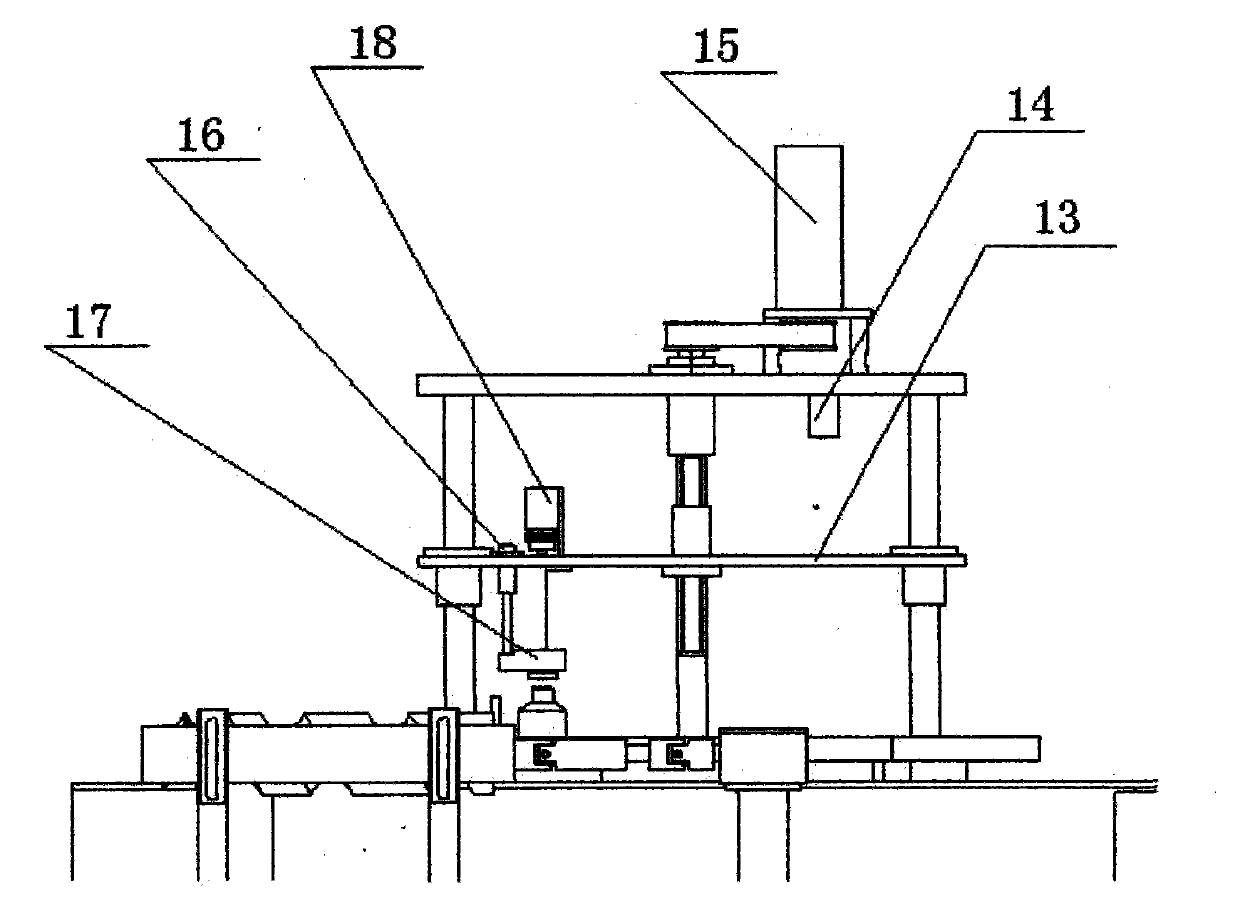

The invention relates to detection equipment of the inner wall of an opaque glass bottle, which adopts stretching-type reflective mirror and machine vision principles, and analyzes the collected images through a computer to automatically remove disqualified bottles. The detection equipment mainly comprises a fast bottle feeding chain channel, a main control box, a camera for detecting a bottle bottom, a disqualified bottle chain channel, a striker A, a striker B and a front-end detection part, and the whole equipment is in a series structure; and defective products are screened by the front-end detection part and the camera for detecting the bottle bottom. The whole equipment has high degree of automation, high screening success rate and convenient maintenance.

Description

technical field The invention relates to a wine packaging machine, in particular to a detection device for the inner wall of a glass packaging bottle for opaque liquor. Background technique At present, in order to protect the environment and reduce production costs, many wineries use recycled bottles to package liquor after cleaning and inspection. Because the general wine bottle is a transparent glass bottle, the cleanliness of the inner wall of the bottle can be judged by visual inspection after cleaning, and it is also available under high output. Using the imported empty bottle inspection machine, compared with the use of new bottles in the whole process of recycling old bottles, the cost of wine bottles can be saved by about 60%. However, in recent years, many wineries use opaque glass bottles to package liquor. Because the inner wall is invisible, it cannot be easily recycled through direct visual inspection, and even some special detection machines cannot detect it, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/90B07C5/34

Inventor 袁宏杰李晓春袁帅峰钟建

Owner CHANGSHA LIGHT IND MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com