Aerostatic bearing and method for production thereof

A gas static pressure and bearing technology, which is applied in the field of manufacturing micro-holes and manufacturing the gas static pressure bearing, can solve the problems of limiting the maximum wall width, weakening the bearing plate, pressure difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

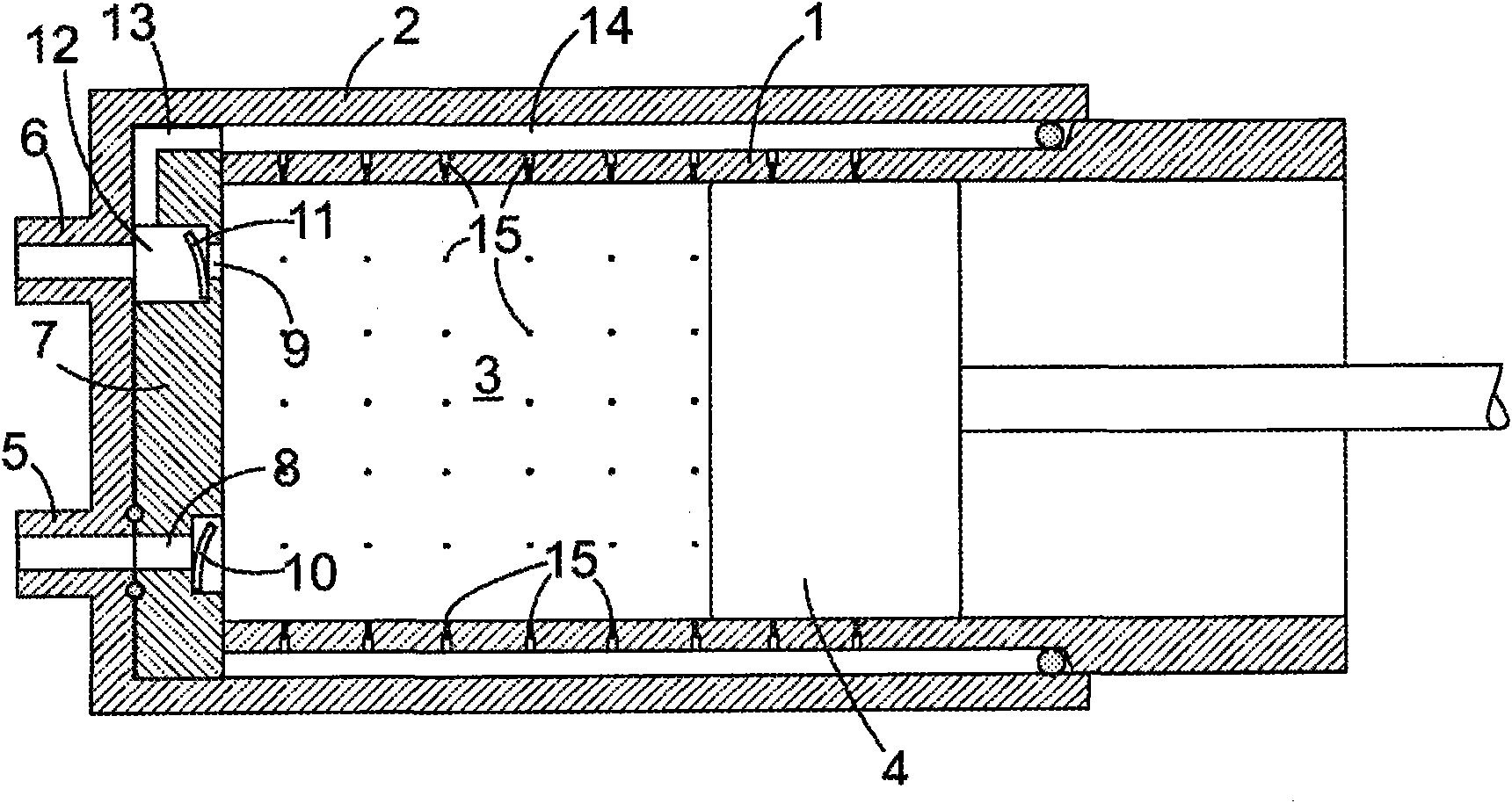

[0031] exist figure 1 The aerostatic bearing, shown in axial cutaway in , comprises a cylindrical pipe section 1, a cup 2 screwed around one end of said pipe section 1 (tube section 1 and cup 2 together define the compression chamber 3) and a piston 4 that can move backwards and forwards in the pipe section 1. An input connector 5 and an output connector 6 are arranged at the bottom of the cup holder. The valve plate 7 in the cup holder 2 forms the front side of the compression chamber 3 . The valve plate 7 comprises holes 8 , 9 aligned with the connections 5 , 6 , each hole accommodating a non-return valve 10 , 11 . The non-return valves 10, 11 are each formed by elastic tongues which, in the released position, sit against the valve seats formed by the shoulders of the holes 8 or 9, respectively; other configurations of non-return valves are also conceivable.

[0032] A connecting line 13 extends from a chamber 12 provided between the one-way valve 11 of the bore and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com