Canned food high temperature sterilizer

A high-temperature sterilization, canned food technology, applied in food preservation, food science, application and other directions, can solve the problems of high labor intensity, large temperature difference, poor sterilization and disinfection effect, etc., to reduce labor intensity and data recording. Detailed, health-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

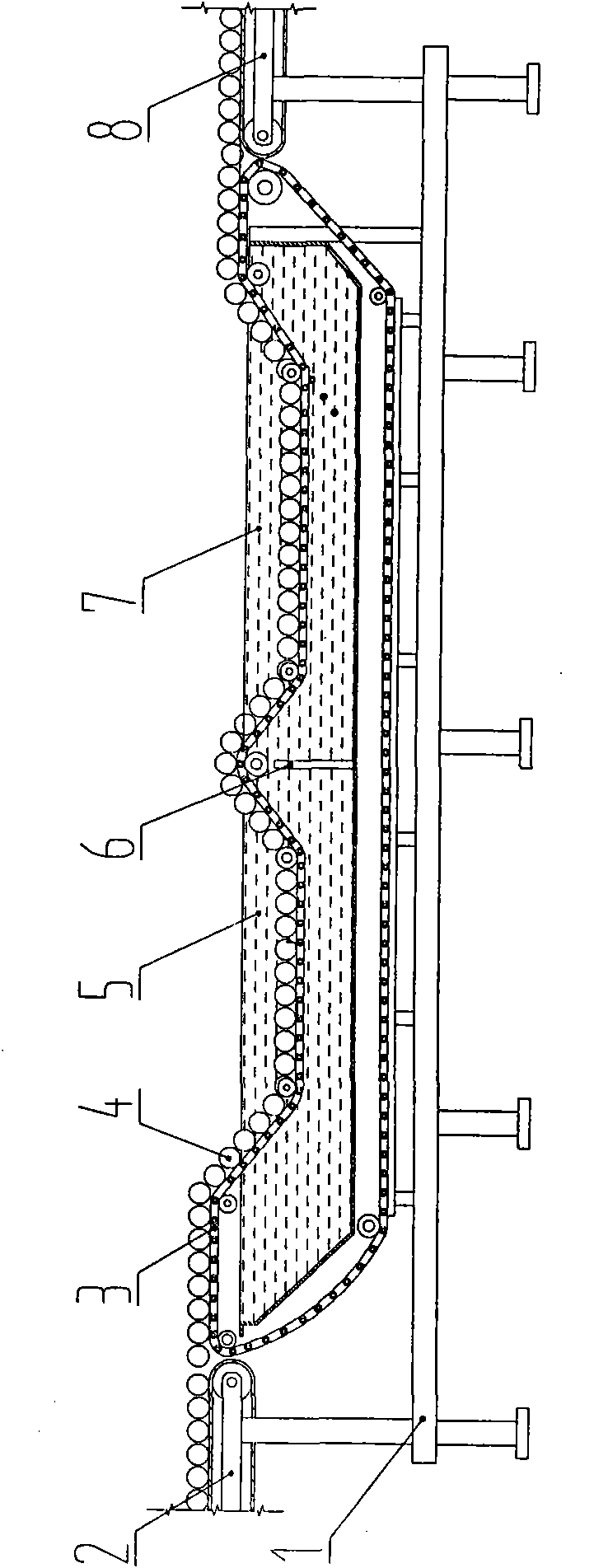

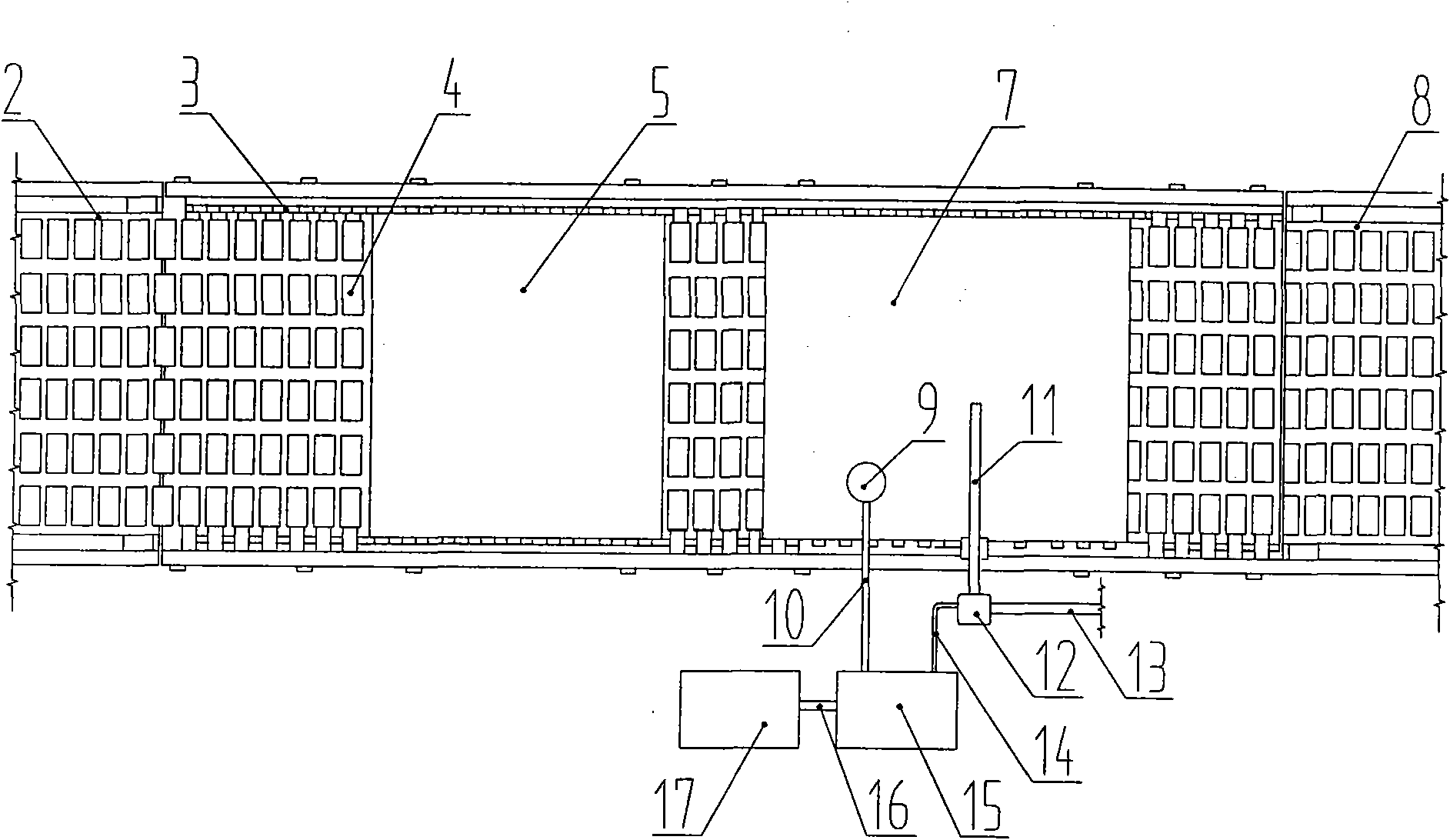

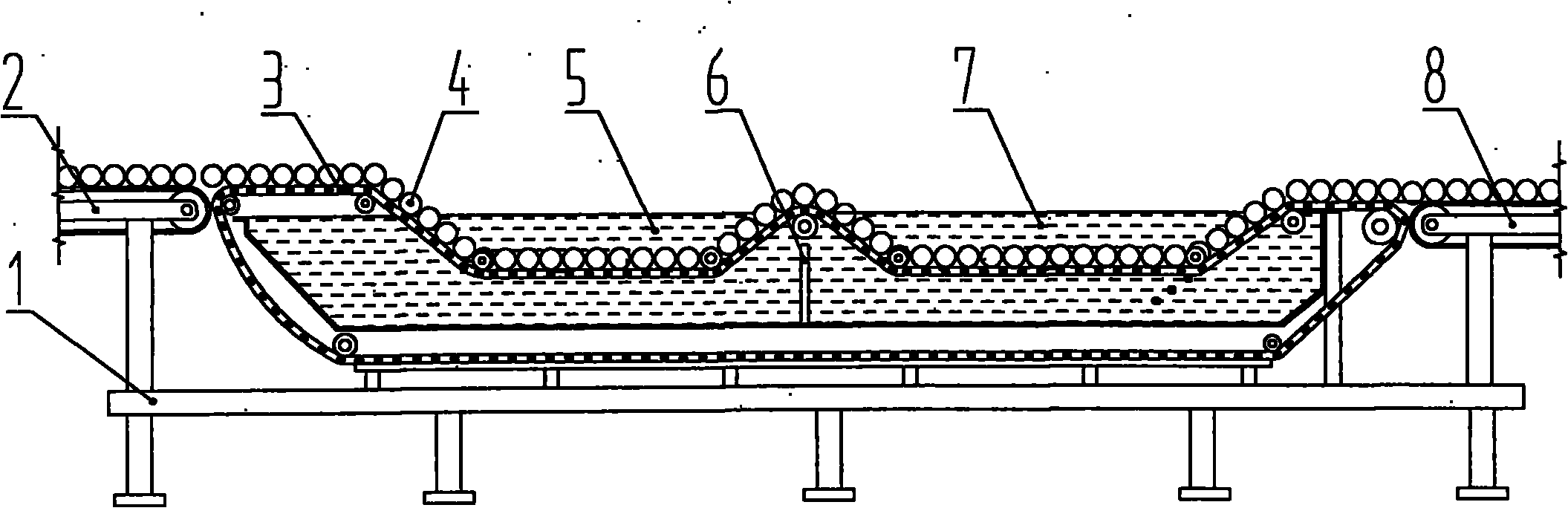

[0015] Such as figure 1 , figure 2 Shown: a high-temperature sterilization and disinfection device for canned food includes: a frame 1, a preheated water tank 5 arranged on the frame 1, a heating and disinfection water tank 7, and a chain-type roller conveyor 3 for transporting canned food, and also includes a frame mounted on the machine The feed conveyor 2 and the discharge conveyor 8 at the two ends of the frame 1 are characterized in that: a temperature sensor 9 and a steam inlet pipe 11 are set in the heating and disinfection water tank 7 .

[0016] The temperature sensor 9 is connected with the control box 15 through the signal line I10; the air intake pipe 11 is connected with the steam tank outside the machine through the electric control gas valve 12 and the gas delivery pipe 13. The electric control air valve 12 is connected with the control box 15 through the signal line II 14; the control box 15 is connected with the display recorder 17 through the signal line II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com