Positioning mould

A technology for positioning molds and molds, which is applied in the field of molds for producing rubber diaphragms of automobile brake air chambers, can solve the problems of blank dislocation and displacement, and high defective rate, achieve accurate and stable positioning, reduce production costs, and prevent peripheral warping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

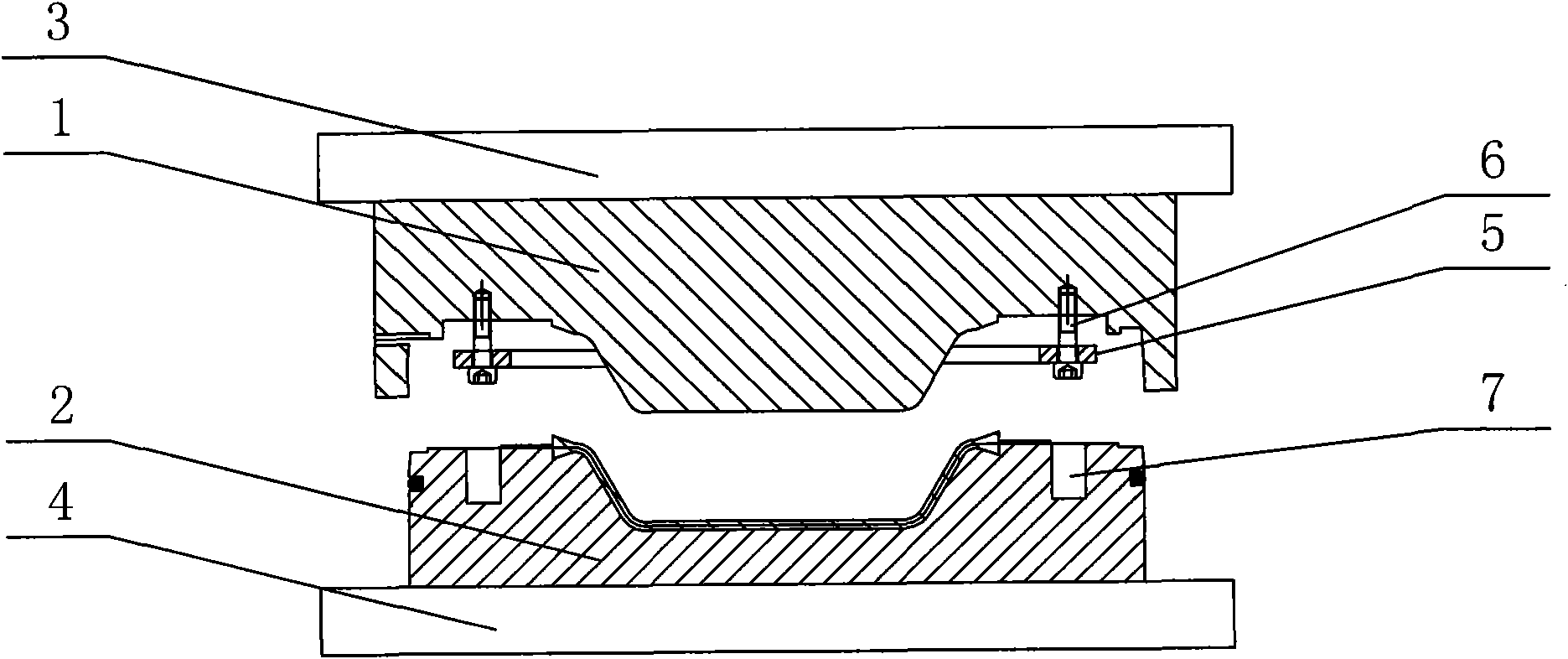

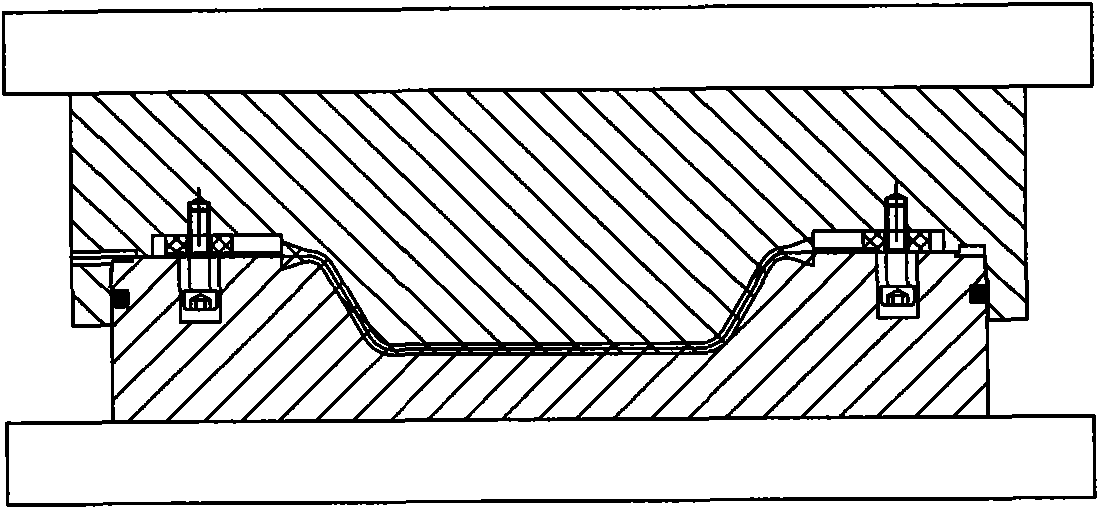

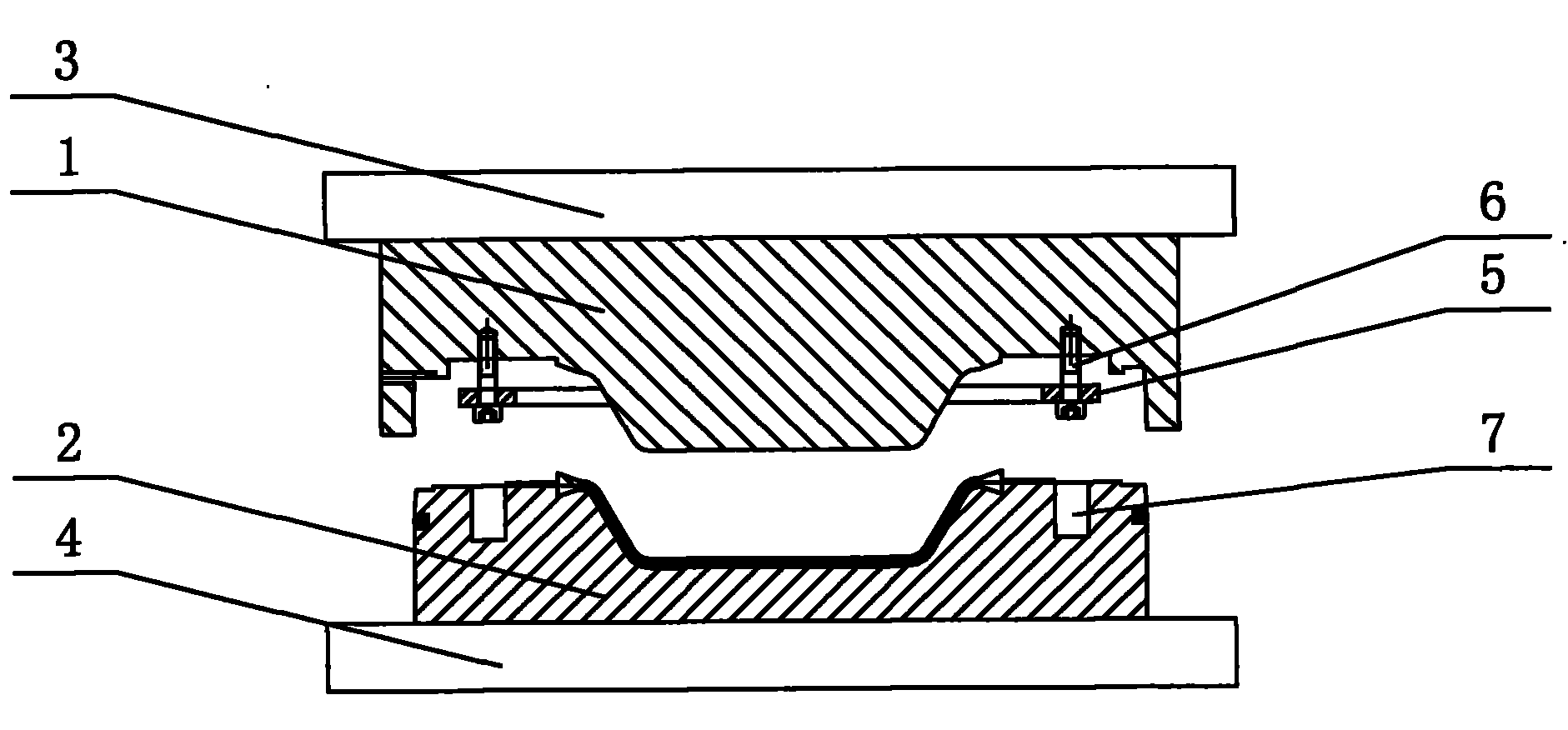

[0013] Such as Figure 1-2 As shown, the positioning mold described in this embodiment, the upper mold 1 and the lower mold 2, the upper mold 1 and the lower mold 2 are respectively connected with the upper hot plate 3 and the lower hot plate 4, and the upper mold 1 and the lower mold 2 are molded together to form The shape of the rubber diaphragm of the automobile brake air chamber, wherein the upper mold 1 is a punch, the lower mold 2 is a die, and the upper mold 1 is provided with a fixed die ring 5 that presses the edge of the rubber diaphragm blank, and the fixed die ring 5 Connected to the inner side of the upper mold 1 by the positioning bolt 6, the positioning ring 5 can be displaced for a certain distance on the positioning bolt 6, and a screw hole 7 is provided on the lower mold 3 corresponding to the positioning bolt 6, so that in the process of mold closing The positioning bolt 6 falls into the positioning hole 7 .

[0014] For the number of positioning bolts 6 us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com