Fuel-free gas igniting and combustion stabilizing method for industrial coal powder boiler

A technology for industrial boilers and pulverized coal, applied in combustion methods, burners for burning powder fuel, burners, etc., can solve problems affecting the adaptability of coal types, achieve good cold start and stable combustion effects, wide adaptability, Beneficial for marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

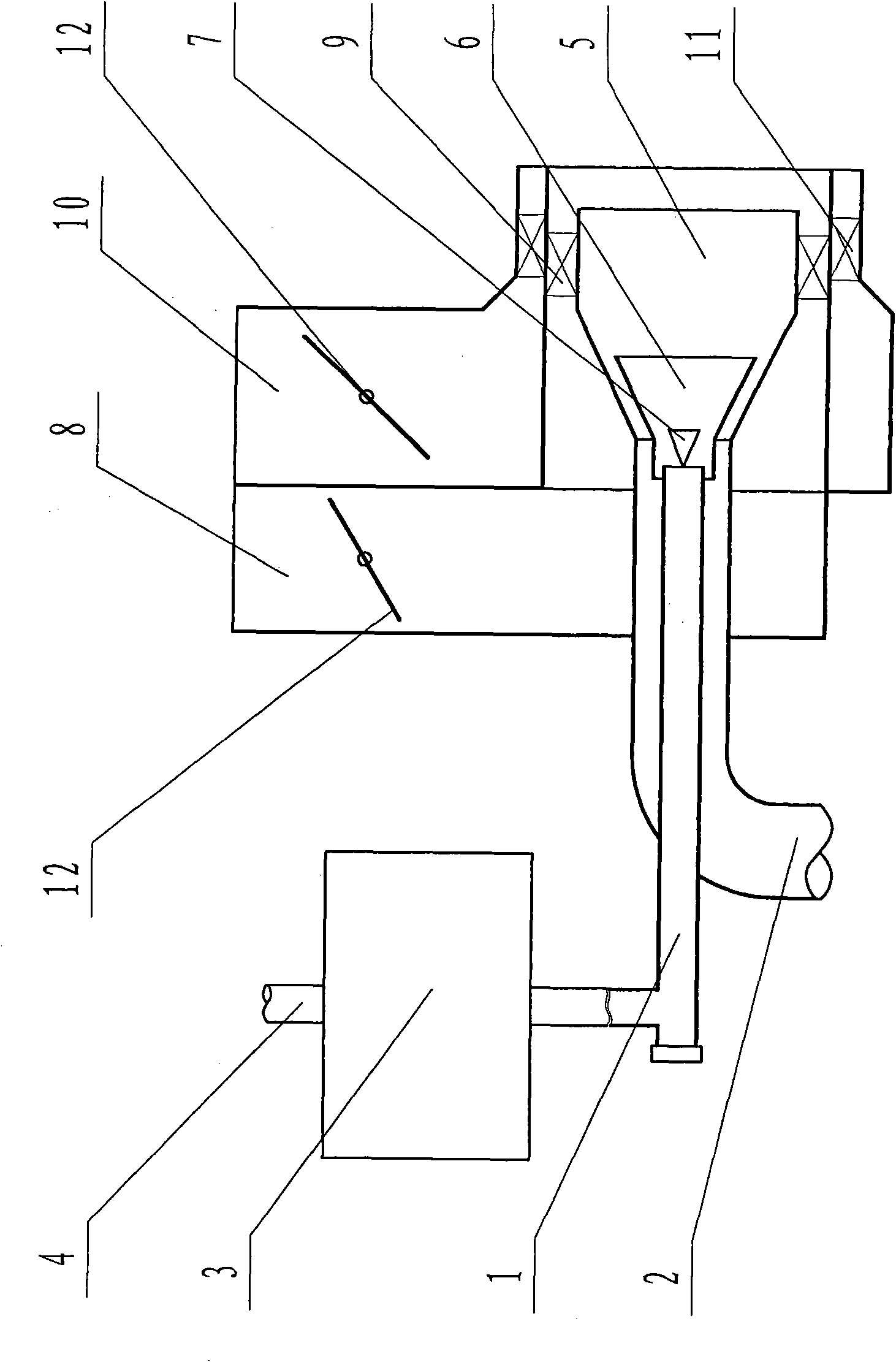

[0014] The method of ignition and stable combustion of oil-free gas for pulverized coal industrial boilers. After the mixture of primary air and coal powder is sprayed out through the primary air pipe 2 with a central pipe 1 at the axis, two strands are formed centered on the axis of the primary air pipe 2. The pulverized coal airflow distributed in the outer layer; ozone-containing air or oxygen is ejected from the central tube 1, and then the gas is ignited by a gas torch, and then the pulverized coal airflow in the inner layer is ignited under the combustion support of ozone-containing air or oxygen, and then the inner layer The pulverized coal flow in the outer layer ignites the pulverized coal flow in the outer layer. The volume content of ozone in the air or oxygen in the center pipe 1 is 7%-8%, the volume of oxygen in the center pipe (1) is 5.5%-7.5% of the oxygen volume in the primary air pipe (2), and the gas point The primary air volume in the primary air duct 2 befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com