Fluorine plastic insulated fireproof control cable

A technology for controlling cables and fluoroplastics, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve problems such as harmful equipment, polluting the environment, and a large amount of hydrogen halide gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

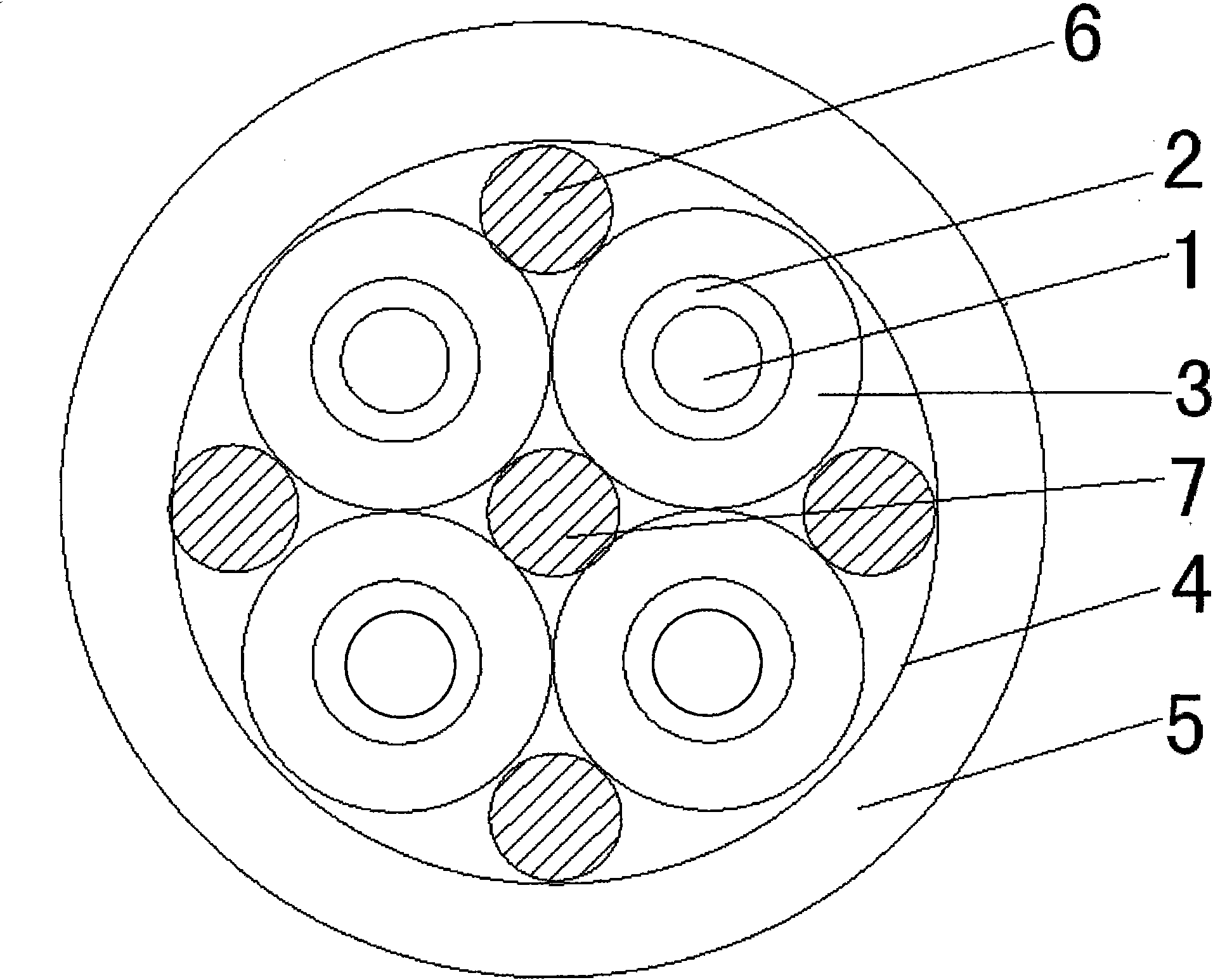

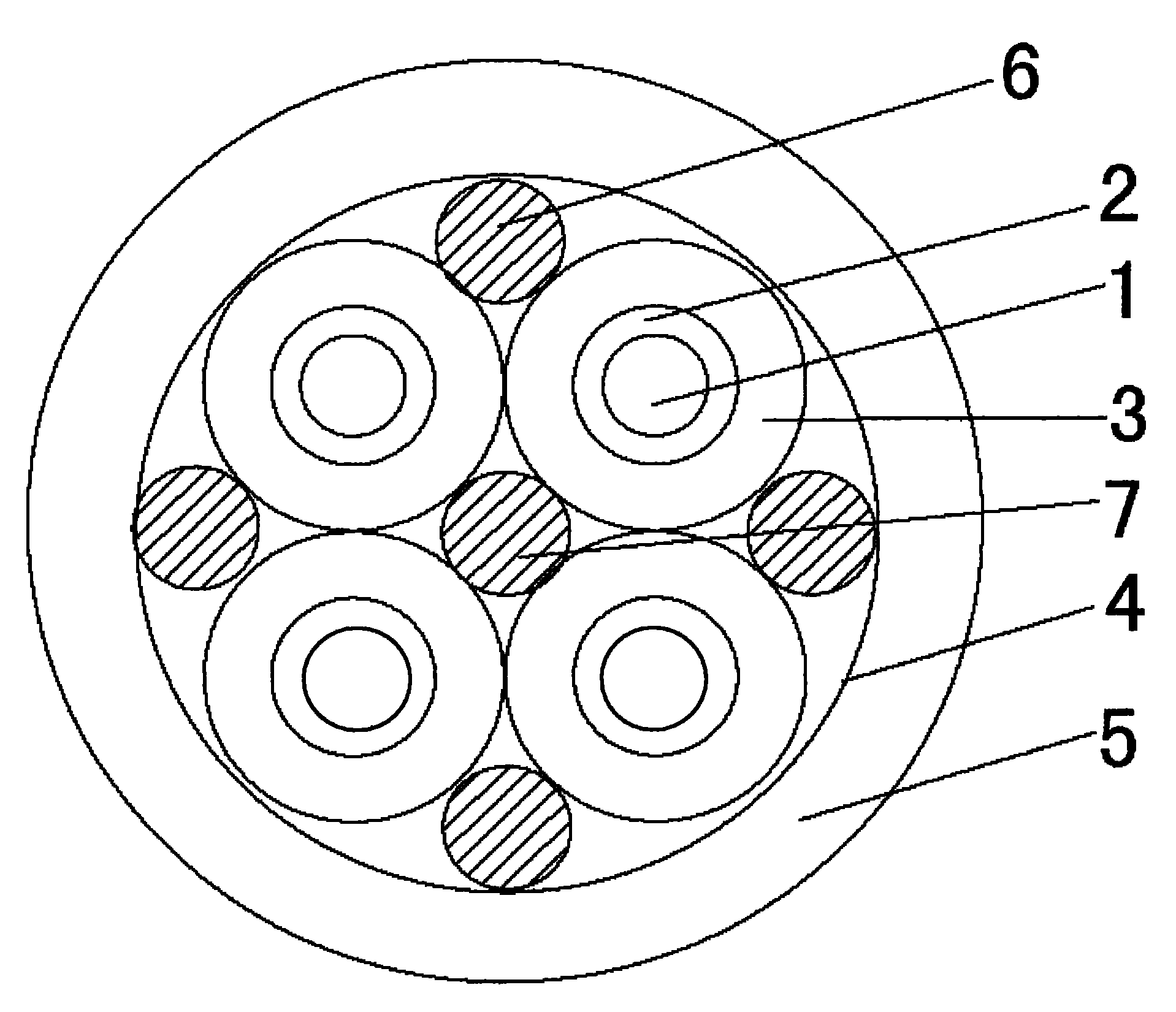

[0005] The figure includes a cable inner core and a cable outer layer wrapped outside the cable inner core. The inside of the cable inner core is a conductive wire core 1, a refractory layer 2, and an insulating layer 3 in sequence from the inside to the outside. The inside of the cable outer layer is from the inside to the outside. The outer layer is a flame-retardant tape 4 and a sheath layer 5 in turn, and a flame-retardant filler 6 is provided in the gap between the outer layer of the cable and the inner core of the cable. Flame-retardant fillers 7 are arranged in the gaps between the inner cores of the cables.

[0006] The number of cable inner cores in the outer layer of the cable is one or more, generally three, four or five are selected. The conductive wire core has two or more layers, each layer has several wire groups with the same cross-section, each wire group has several conductor monofilaments, and the layers are twisted in opposite directions. The conductive co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com