125 DEG C-irradiation crosslinked halogen-free low-smoke flame-retardant insulating material for new-energy vehicle wire

A new energy vehicle, low-smoke flame retardant technology, applied in the field of cable material and its manufacturing, can solve problems such as human health and natural environment threats, achieve good mechanical properties, good flame retardant effect, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

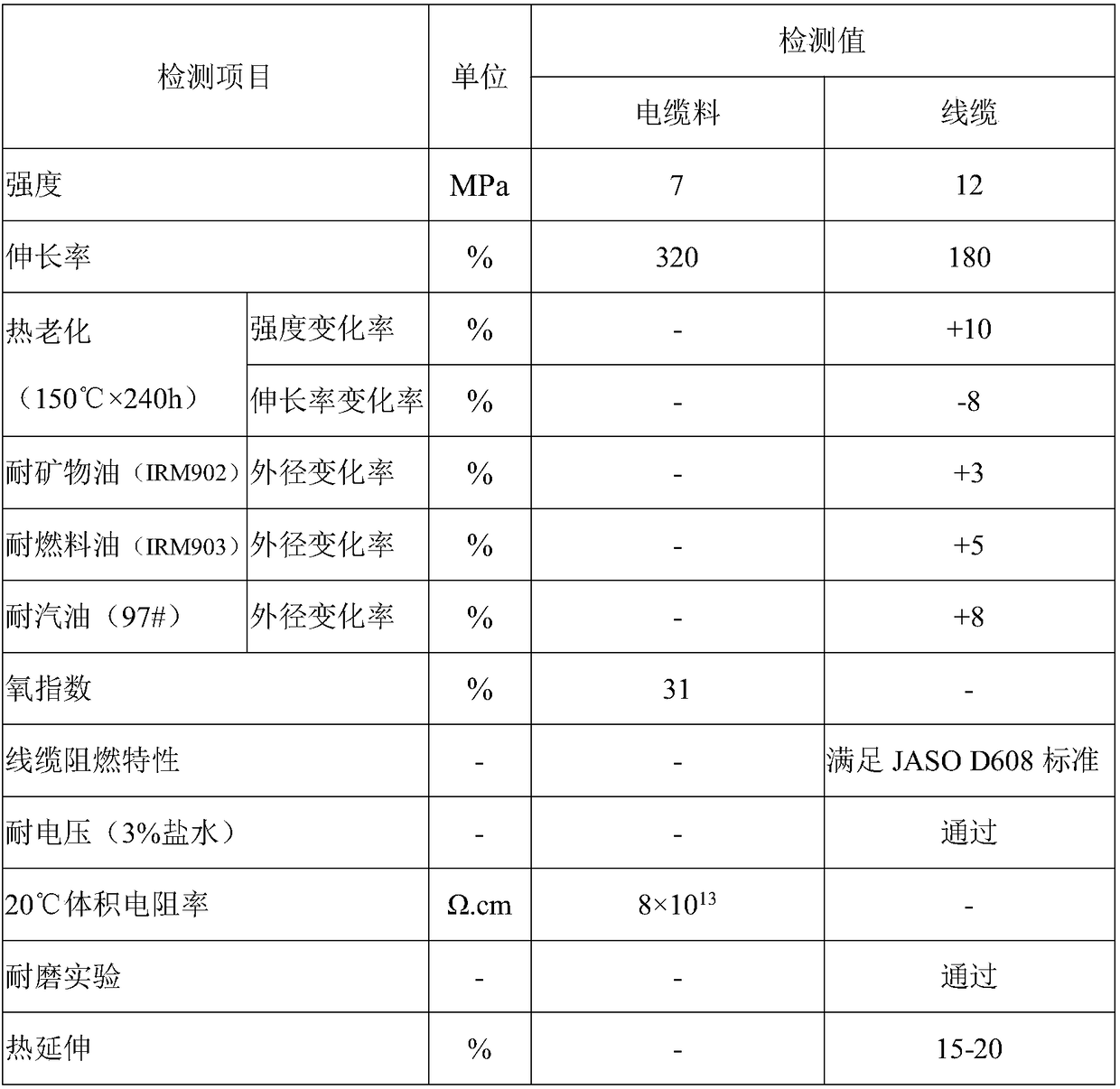

Embodiment 1

[0013] A 125°C irradiation cross-linked halogen-free low-smoke flame-retardant insulating material for new energy automobile lines, which consists of the following raw materials in parts by weight: 15 parts of metallocene linear low-density polyethylene, 50 parts of ethylene ethyl acetate, polyolefin elastic 15 parts of body, 10 parts of compatibilizer, 125 parts of flame retardant, 2.5 parts of triallyl isocyanurate, 3 parts of silicone powder, 2 parts of PE wax, γ-methacryloyl oxide 1 part of propyltrimethoxysilane, 1 part of polysiloxane, 1 part of methyl silicone oil, 1 part of tetrakis [β-(3.5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, sulfur 1 part of di(octadecyl)dipropionate.

[0014] Wherein, the above-mentioned flame retardant is one or both of aluminum hydroxide and magnesium hydroxide.

[0015] Wherein, the above-mentioned compatibilizer is one of maleic anhydride grafted polyolefin elastomer and maleic anhydride grafted ethylene ethyl a...

Embodiment 2

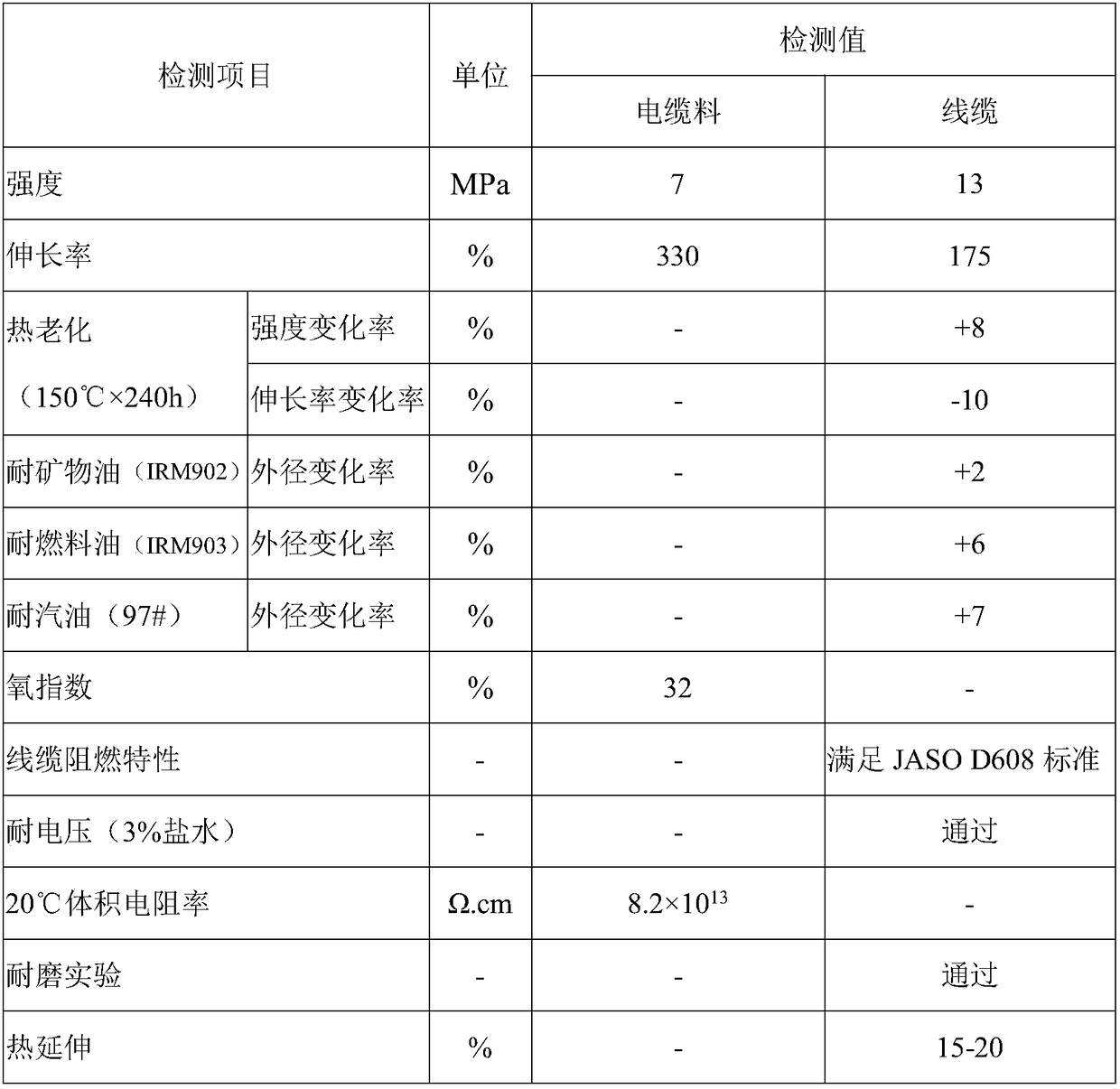

[0022] A 125°C irradiation cross-linked halogen-free low-smoke flame-retardant insulating material for new energy automobile lines, which consists of the following raw materials in parts by weight: 17.5 parts of metallocene linear low-density polyethylene, 55 parts of ethylene ethyl acetate, polyolefin elastic 20 parts of body, 12.5 parts of compatibilizer, 125 parts of flame retardant, 2.5 parts of triallyl isocyanurate cross-linking aid, 3 parts of silicone powder, 2 parts of PE wax, γ-methacryloyl oxide 1 part of propyltrimethoxysilane, 1 part of polysiloxane, 1 part of methyl silicone oil, 1 part of tetrakis [β-(3.5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, sulfur 1 part of di(octadecyl)dipropionate.

[0023] Table two is the detection result of embodiment 2 cable material and the produced wire and cable;

[0024] Table II

[0025]

Embodiment 3

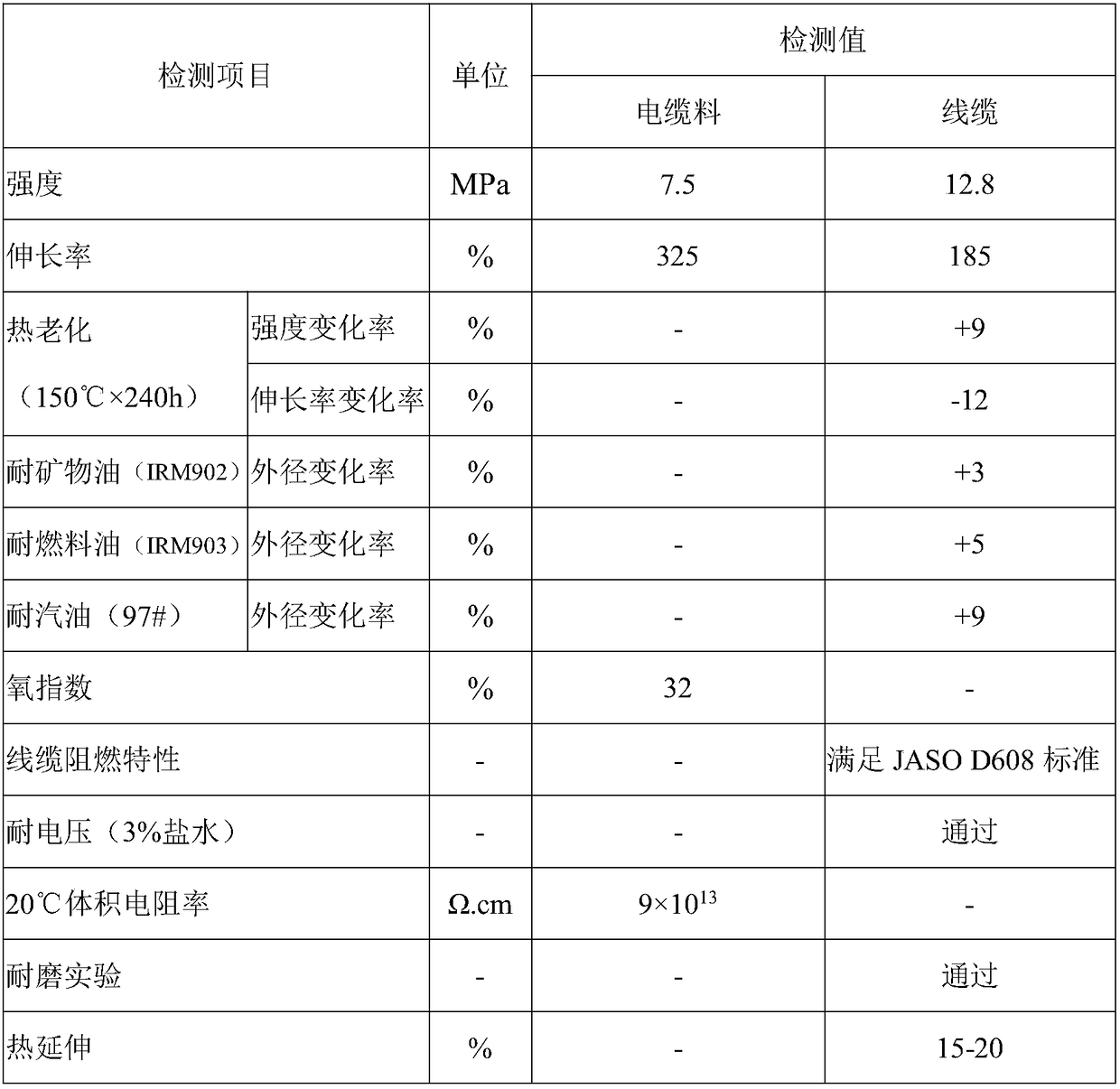

[0027] A 125°C irradiation cross-linked halogen-free low-smoke flame-retardant insulating material for new energy automobile lines, which consists of the following raw materials by weight: 20 parts of metallocene linear low-density polyethylene, 60 parts of ethylene ethyl acetate, polyolefin elastic 25 parts of body, 15 parts of compatibilizer, 125 parts of flame retardant, 2.5 parts of crosslinking aid triallyl isocyanurate, 3 parts of silicone powder, 2 parts of PE wax, γ-methacryloyl oxide 1 part of propyltrimethoxysilane, 1 part of polysiloxane, 1 part of methyl silicone oil, 1 part of tetrakis [β-(3.5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, sulfur 1 part of di(octadecyl)dipropionate.

[0028] Table three is the detection result of embodiment 3 cable material and the electric wire and cable produced;

[0029] Table three

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com