Patents

Literature

31results about How to "Comply with ROHS standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

Under-coated coating of water-based UV-light curing vacuum coating

InactiveCN101787243AStrong adhesionImprove surface cleanlinessVacuum evaporation coatingSputtering coatingWater basedSolubility

The invention relates to the technology field of coating, in particular to an under-coated coating of water-based UV-light curing vacuum coating; the invention comprises modified polyurethane acrylic acid, an evocating agent, a surface additive, a latent solvent and water, wherein the modified polyurethane acrylic acid is obtained through synthesis of high molecular polymer, chain extender, an emulsifying agent, alight curing agent, a catalyst and organic amine; the invention not only has high surface cleanness and good leveling property, but also has strong adhesive force, particularly has the water solubility and the oil solubility simultaneously, has wide application range, and conforms to the EU ROHS standard.

Owner:GUANGDONG ZHICHENG CHEM

Frosted-surface PCM color-coated steel plate and processing method thereof

InactiveCN110893395AHigh temperature resistantImprove scratch resistancePretreated surfacesSpecial surfacesChemical resistancePassivation

The invention relates to the technical field of frosted surfaces, and in particular to a frosted surface PCM color-coated steel plate. The plate comprises a color-coated plate body, a first passivation layer is arranged in the lower surface of the color-coated plate body, a back paint layer sprayed on the outer side of the first passivation layer, a second passivation layer is arranged in the upper surface of the color-coated plate body, a weather-proof primer layer arranged in the upper surface of the second passivation layer, and a color finish paint layer sprayed in the upper surface of the weather-proof primer layer. The steel plate has the physical properties of high temperature resistance, chemical resistance and the like, can improve the scratch resistance of the coating and reducethe damage in the use process by adding the colored finish paint layer, has a high use value, conforms to the national green and environment-friendly requirements, does not contain heavy metals, andconforms to the European Union ROHS standard.

Owner:SHANDONG JINGHONG INTELLIGENT TECH CO LTD

Spraying coating material

InactiveCN101250356ASimple spraying processEasy to operateLiquid surface applicatorsCellulose coatingsCelluloseSpray coating

The invention discloses spray plating paint, which comprises components with percentage by weight of 10-22 wt% cellulose resin, 6-12 wt% vinyl chloride-acetate copolymer, 0.25-05 wt% micro-molecular directing auxiliary agent, 1.5-4.0 wt% silver slurry and 61.5-82.3 wt% solvent. The spray plating effect of the paint is same as electroplating products, the paint can be used on various plastic adhesive electric products such as ABS, PC, PC+ ABS and the like, and the spraying technology is simple and can be operated conveniently.

Owner:HUIZHOU CHANGRUNFA PAINT

Non-phosphate film agent

InactiveCN101660154BImprove rust resistanceStrong bondMetallic material coating processesContinuous usePhosphate

The invention relates to a non-phosphate film agent, comprising the following components by weight percent: 2.5-4.5% of succinic acid, 0.8-2% of sodium molybdate, 0-3% of sodium nitrate, 0-5% of citric acid, 0-0.5% of sodium fluoride, 0-0.8% of tannin, 0-1.5% of oxalic acid, 0-0.05% of sodium dodecyl sulfate, the balance of water. The invention has the advantages that: the non-phosphate film agent contains no phosphor, thus being really environmentally friendly; antirust performance is good; combining power with molding powder and paint and adhesive force are all excellent, thus meeting ROHS standard; when in use, aluminum alloy work piece, galvanized work piece and steel work piece can be placed in the same bath solution for coating, thus greatly simplifying the production technology andreducing equipment investment; and suspended matter produced when being continuously used for three months is only 10-20 kilograms, thus solving the difficult problem that one day is stopped in production per week for clearing phosphated slag when using phosphoric film agent.

Owner:NANJING JIUJIU CHEM TECH DEV

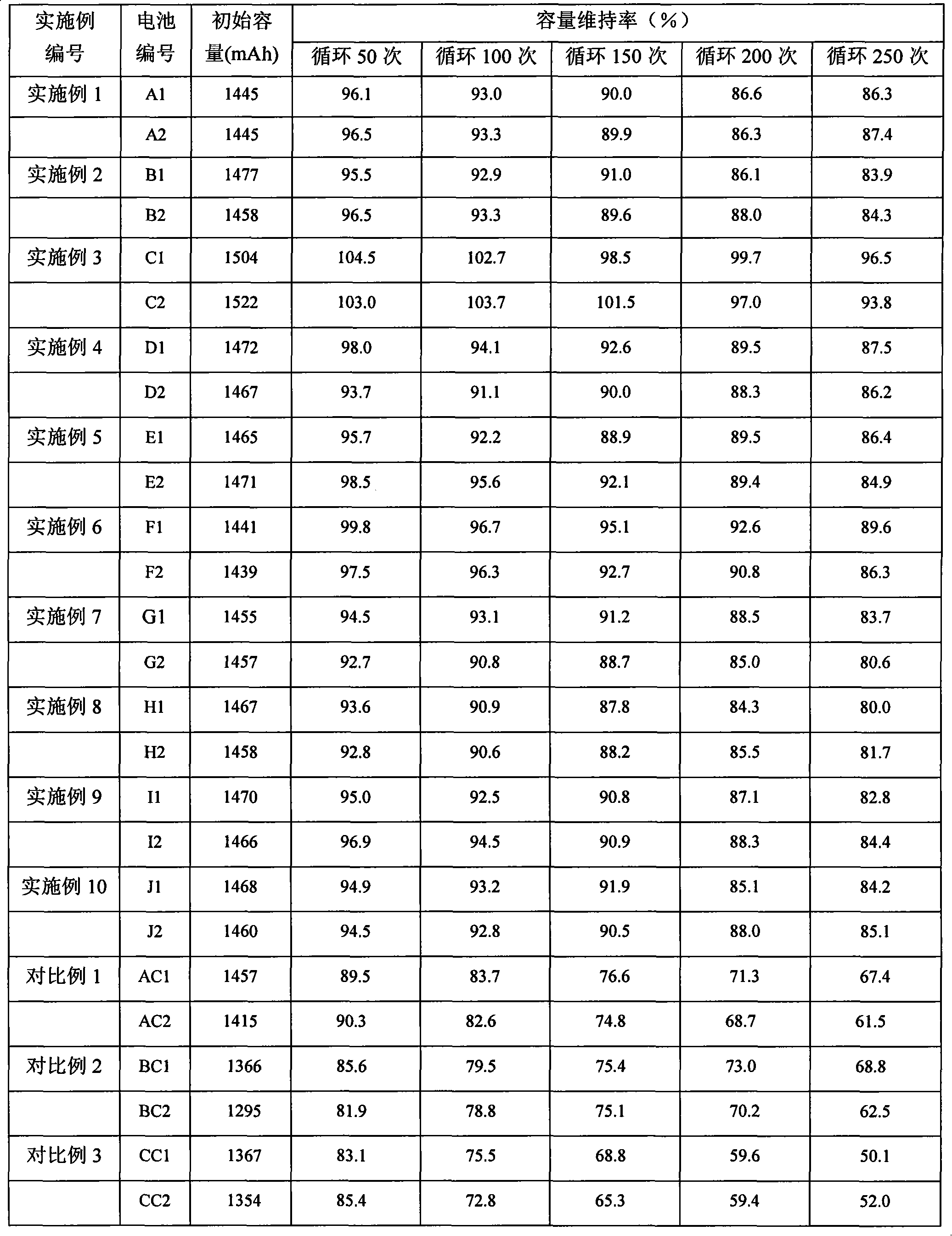

Cadmium negative pole, preparation method thereof and secondary nickel-cadmium battery containing same

InactiveCN101609889AIncreased initial capacity playImprove initial capacity playAlkaline accumulator electrodesNickel accumulatorsAdhesiveNickel–cadmium battery

The invention relates to a cadmium negative pole used for a secondary nickel-cadmium battery. The cadmium negative pole comprises a current collector and a negative pole material covered on the current collector, and the negative pole material contains a negative pole active substance and negative pole adhesive, wherein the negative pole material also contains a conductive metallic oxide which contains at least two metallic elements. The growth of cadmium dendritic crystals of a battery prepared by adopting the cadmium negative pole is effectively restrained in a charging process, thereby better meeting the requirements on the low-current charge and the high-current discharge of the battery.

Owner:BYD CO LTD

Environment-friendly and pollution-free aluminum product brazing wire and manufacturing process thereof

InactiveCN104439754AZero pollutionProtect your healthWelding/cutting media/materialsSoldering mediaPotassium fluorideRare earth

The invention discloses an environment-friendly and pollution-free aluminum product brazing wire. The melting temperature of the brazing wire ranges from 520 DEG C to 560 DEG C, and the diameter of the brazing wire ranges from 1.6 mm to 4.0 mm. The brazing wire comprises, by mass, 5%-10% of potassium fluoride, 5%-15% of rare earth, 10%-25% of aluminum, 5%-15% of silicon, 2%-10% of bismuth and the balance of copper. All materials adopted for the aluminum self-fluxing material are environmentally friendly and meet the ROHS standard, so that zero environment pollution is achieved, and accordingly the health of operators is protected; no corrosive material is adopted, so that acid pickling after brazing is omitted, and accordingly the production cost is lowered.

Owner:河南银升焊接材料有限公司

Novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent prepared from biological inositol and preparation method and application of novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent

ActiveCN104894550AZero pollutionLess investmentMetallic material coating processesOrganic acidHazardous substance

The invention relates to a novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent prepared from biological inositol and a preparation method and application of the novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent. The novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent is prepared from the biological inositol and polybasic organic acid in the mol ratio of (1:1)-(1:10). The novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent has the advantages that the prepared coating film agent is free from phosphorus, fluoride and heavy metal and is truly environmental-friendly; the coating film agent is high in anti-rust performance, excellent in coupling force and adhesive force for molding powder and paint, low in investment and using requirement, applicable to different kinds of metal, high in adhesive force, and capable of meeting the ROHS (Restriction of the use of certain Hazardous Substances) compliant and solving the problems of high fluorine content, poor stability during use, complexity in operation and control and the like of an existing non-phosphorus coating film agent fundamentally.

Owner:南京金环生物技术有限公司

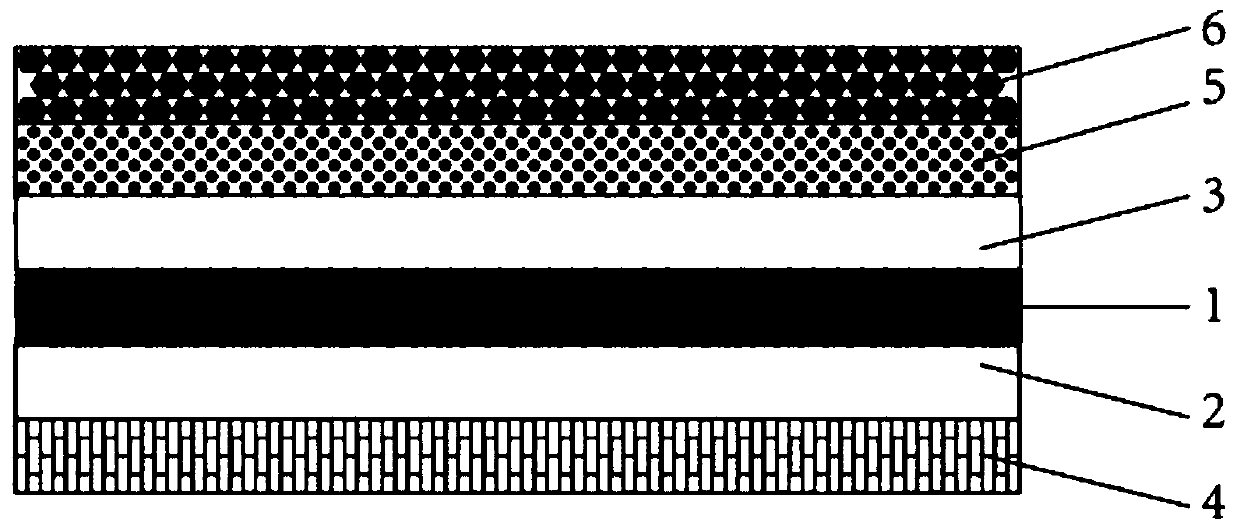

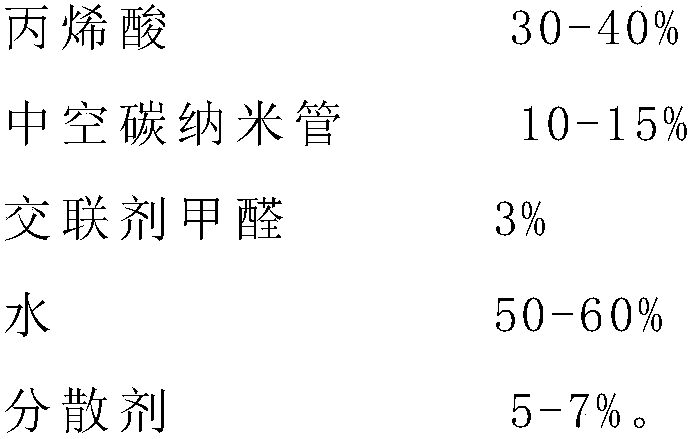

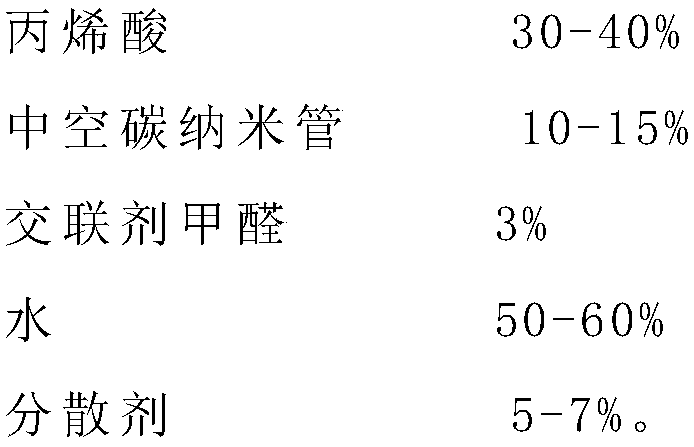

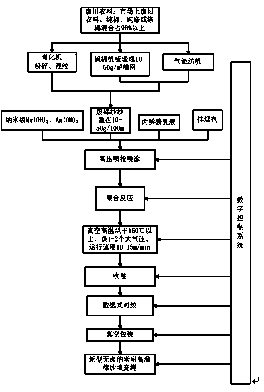

High-insulation shielding wrapping tape and preparation method thereof

InactiveCN109049924AHigh temperature resistanceComply with ROHS standardLamination ancillary operationsSynthetic resin layered productsFiberHeat resistance

The invention provides a high-insulation shielding wrapping tape. The high-insulation shielding wrapping tape is composed of upper-layer functional composite fiber cloth, a middle-layer conductive carbon black colloid layer and lower-layer functional composite fiber cloth. The invention further provides a preparation method of the high-insulation shielding wrapping tape; the preparation method selects high-elasticity insulating cloth made of functional composite fibers, and a high-viscosity conductive composite binding agent is produced by applying a polymerization reaction technology; a clamping type dry type compounding technology is adopted and vacuum drying is carried out to prepare the high-insulation shielding wrapping tape. The high-insulation shielding wrapping tape has the characteristics of insulating surface, conductive and shielding inner part, heat resistance, light specific gravity, softness, easiness for wrapping, environment protection and the like and is widely applied.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

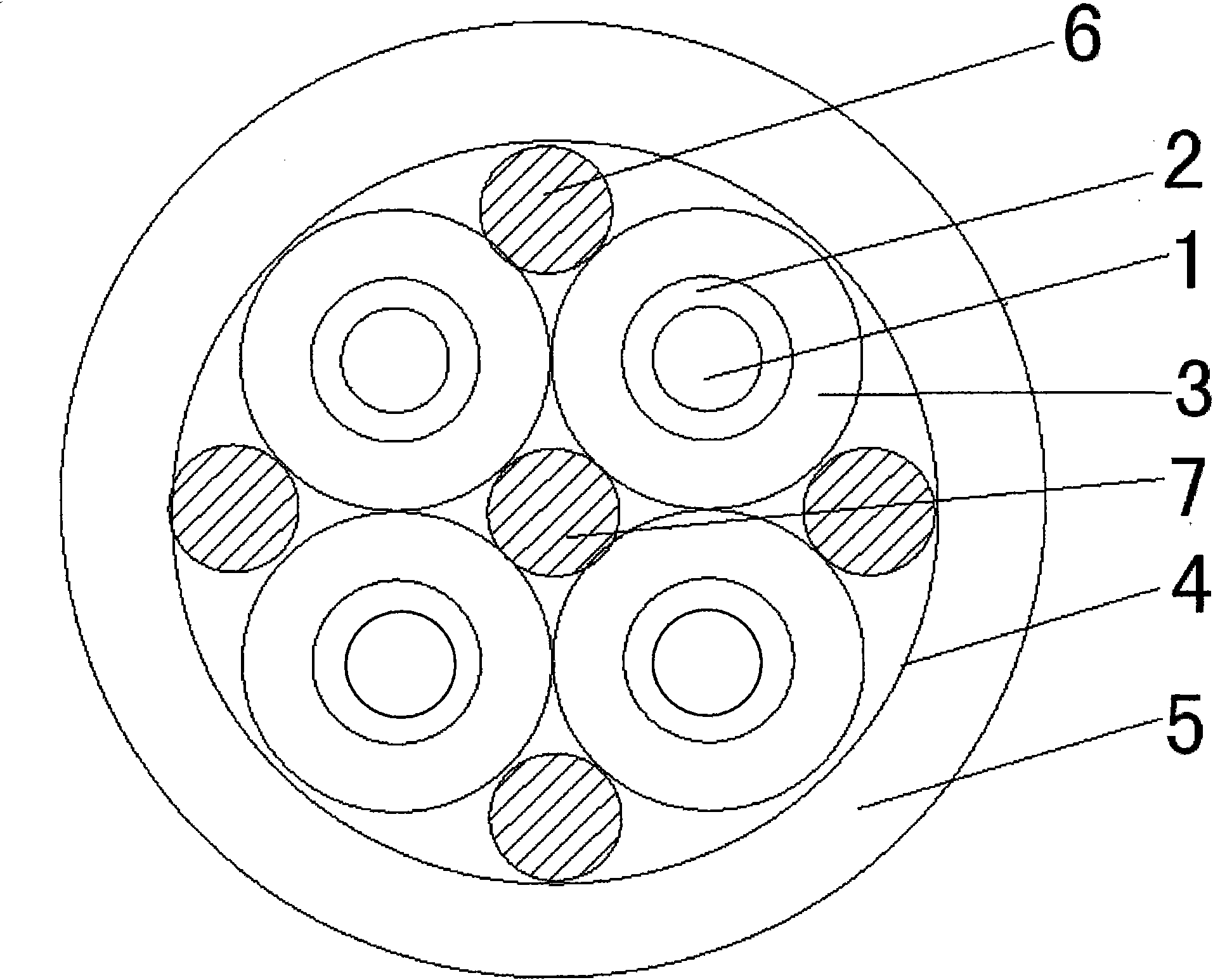

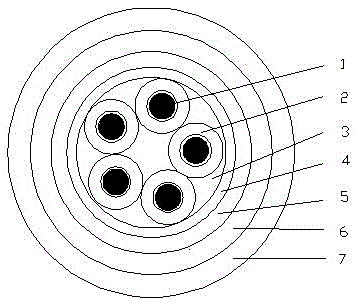

Fluorine plastic insulated fireproof control cable

InactiveCN101872656ASo as not to cause "secondary disasters"Will not cause "secondary disaster"Insulated cablesInsulated conductorsEngineeringTemperature resistance

The invention relates to a fluorine plastic insulated fireproof control cable which comprises an inner cable core and an outer cable layer coated outside the inner cable core, wherein the interior of the inner cable core sequentially comprises a conductor wire core, a fireproof layer and an insulating layer from inside to outside; the interior of the outer cable layer sequentially comprises a flame retardant coating belt and a jacket layer from inside to outside; and a gap between the outer cable layer and the inner cable core is internally provided with a flame retardant filler. Both the insulating layer and the jacket layer of the cable are made of fluorine plastic, and the cable is a chemically stable, flame retardant, halogen free and environmental-friendly material resistant to high and low temperature, fire and corrosion. During combustion, the cable release no harmful gas and smog, can be used in hostile and special environment at about 200 DEG C and has clean and smooth appearance, weather proofing, chemical corrosion resistance, good stability, high and low temperature resistance, low smog, no halogen, environmental protection and flame retardance.

Owner:上海索谷电缆集团有限公司

Top-coated coating of water-based UV-light curing vacuum coating

InactiveCN101787240AHigh hardnessGood wear resistanceVacuum evaporation coatingSputtering coatingSolventChemistry

The invention relates to the technology field of coating, in particular to a top-coated coating of water-based UV-light curing vacuum coating; the invention is composed of modified polyurethane acrylic acid, an evocating agent, a surface additive, a latent solvent and water, wherein the modified polyurethane acrylic acid is obtained by synthesis of high molecular polymer, chain extender, an emulsifying agent, a light curing agent, a catalyst and organic amine; the invention not only has high hardness and good wear resistance, but also has strong adhesive force to the metal, particularly has the water solubility and the oil solubility simultaneously, has wide application range, and conforms to the EU ROHS standard.

Owner:GUANGDONG ZHICHENG CHEM

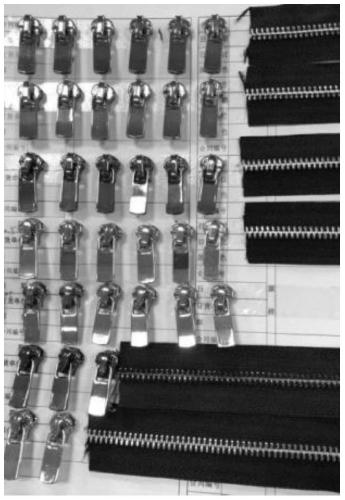

Coloring treatment method of metal zipper component and metal zipper

InactiveCN111441053ASimple processingEasy to operateSlide fastenersMetallic material coating processesEpoxyPolymer science

The invention relates to the technical field of zippers and provides a coloring treatment method of a metal zipper component and the metal zipper. The coloring treatment method comprises the followingsteps: S1, a primary-color metal zipper component is subjected to transparent resin treatment to form a transparent resin coating on the component, wherein the main component of the transparent resincoating is epoxy resin; S2, the zipper component after transparent resin treatment makes contact with a dye solution, wherein the dye solution contains acid dye to color the component; and S3, the colored zipper component is subjected to transparent resin treatment to obtain the metal zipper component after coloring treatment. The method colors the metal zipper component with the dye solution, has the characteristic of rich color personalized decoration and has no special limitation for metal components. The method is simple and convenient in processing operation, high in efficiency, low in cost, safe and environmentally friendly and completely conforms to the ROHS standard.

Owner:ZHEJIANG WEIXING IND DEV

Red copper member natural color passivation process

InactiveCN106167899AImprove corrosion resistanceMeet the protection requirementsMetallic material coating processesAcid washingRoom temperature

The invention discloses a red copper member natural color passivation process, which comprises: immersing a red copper member into a solution a, and removing oil; at a room temperature, immersing the red copper member into tap water, and carrying out water washing; polishing the red copper member through a solution b; at a room temperature, carrying out flowing water washing on the red copper member through tap water; removing surface floating copper from the red copper member through a solution c; at a room temperature, carrying out flowing water washing on the red copper member through tap water; carrying out acid washing on the red copper member through a solution d; carrying out flowing water washing on the red copper member through tap water; carrying out passivation on the red copper member through a copper member passivation agent; carrying out flowing water washing on the red copper member through tap water; immersing the red copper member into a solution e; carrying out flowing water washing on the red copper member through tap water; carrying out blow drying on the red copper member through compressed air; and drying the obtained red copper member at a temperature of 80-110 DEG C. According to the present invention, the natural color passivation operation is performed on the red copper member through the steps, such that the corrosion resistance is improved, the general protection requirements are met, and the European Union ROHS standard is met.

Owner:ANHUI DONGFENG MACHINERY & ELECTRONICS TECHNCO

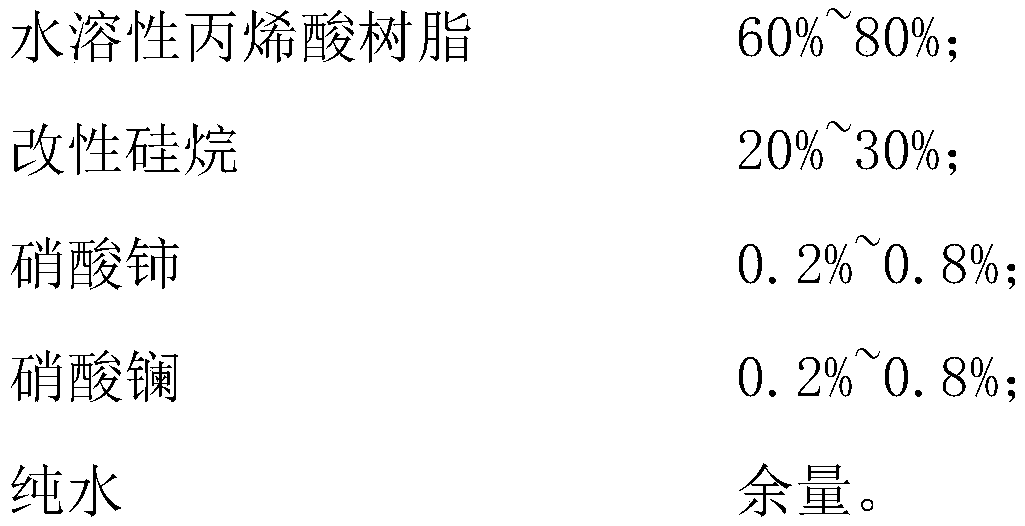

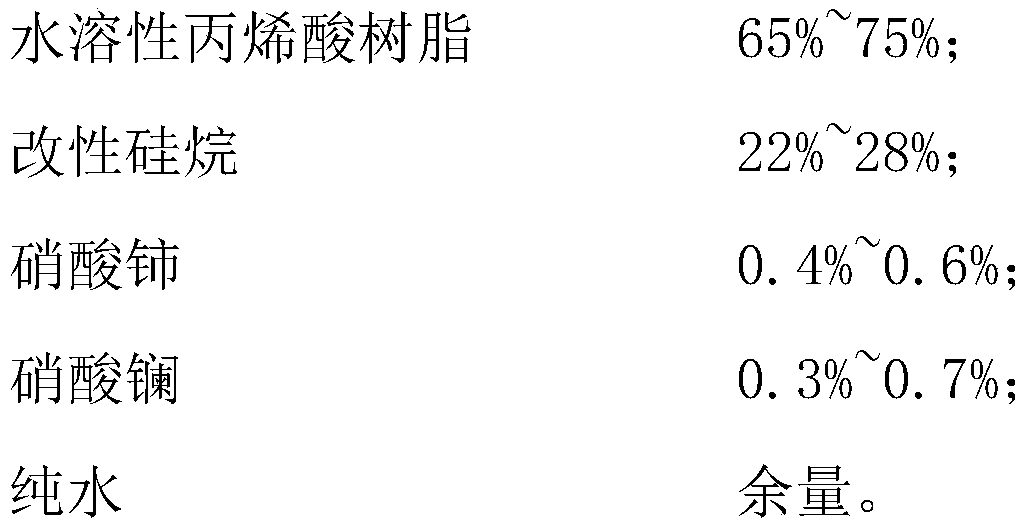

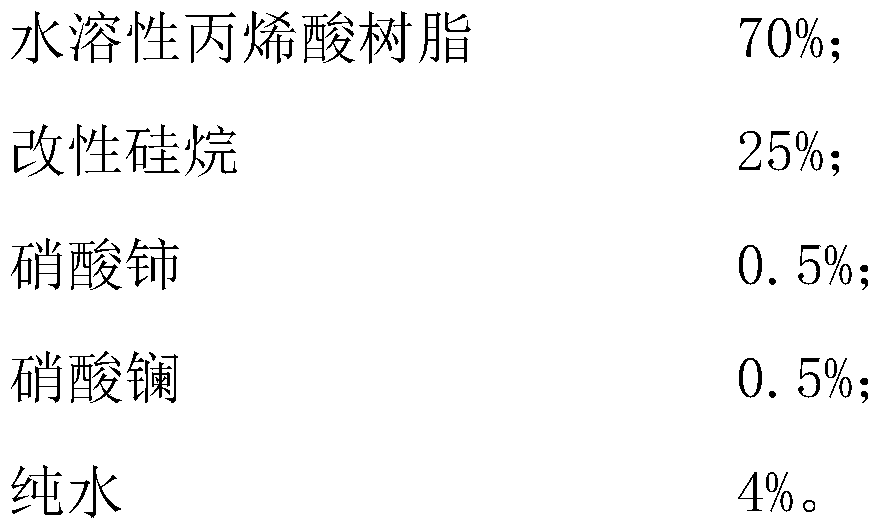

Highly corrosion-resistant zinc coating sealing agent

InactiveCN109735182AImprove neutral salt spray resistanceImprove test resultsAnti-corrosive paintsNitrateHazardous substance

The invention discloses a highly corrosion-resistant zinc coating sealing agent. The highly corrosion-resistant zinc coating sealing agent is composed of 60-80% of water-soluble acrylic resin, 20-30%of modified silane, 0.2-0.8% of cerous nitrate, 0.2-0.8% of lanthanum nitrate and pure water as balance. The highly corrosion-resistant zinc coating sealing agent is a novel thin and uniform sealing agent and can improve the salt fog testing performance of common zinc coatings by 2-3 times; meanwhile, the highly corrosion-resistant zinc coating sealing agent is high in environment-friendly performance and meet the ROHS (restriction of the use of certain hazardous substances) standards of the European Union, and compared with common commercially available products, can prolong the service cycleof working liquor by more than 2 times; besides, the highly corrosion-resistant zinc coating sealing agent is higher in back-plating demolding performance and rack cleaning performance compared withthe commercially available products.

Owner:宁波市鄞州艾博化工科技有限公司

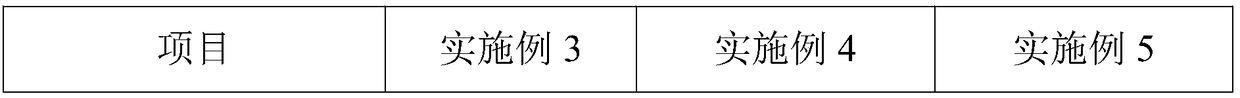

Flame-retardant PVC injection molding material for branch cables and preparation method thereof

ActiveCN104744850BComply with ROHS standardEnvironmentally friendlyPlastic/resin/waxes insulatorsWaxPlasticizer

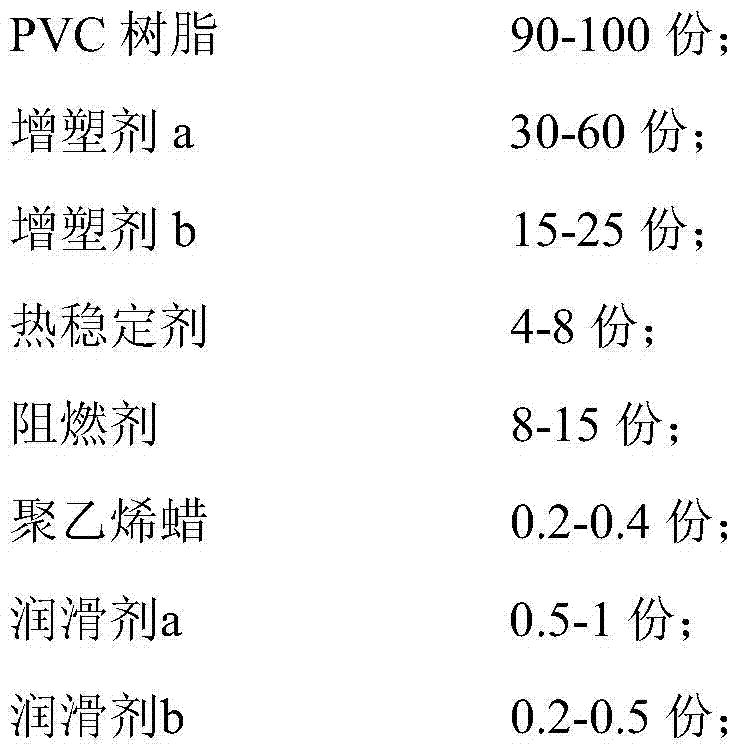

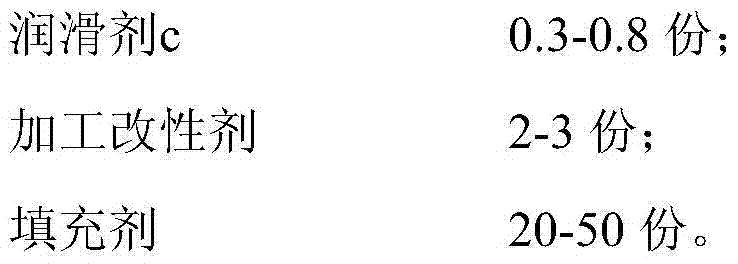

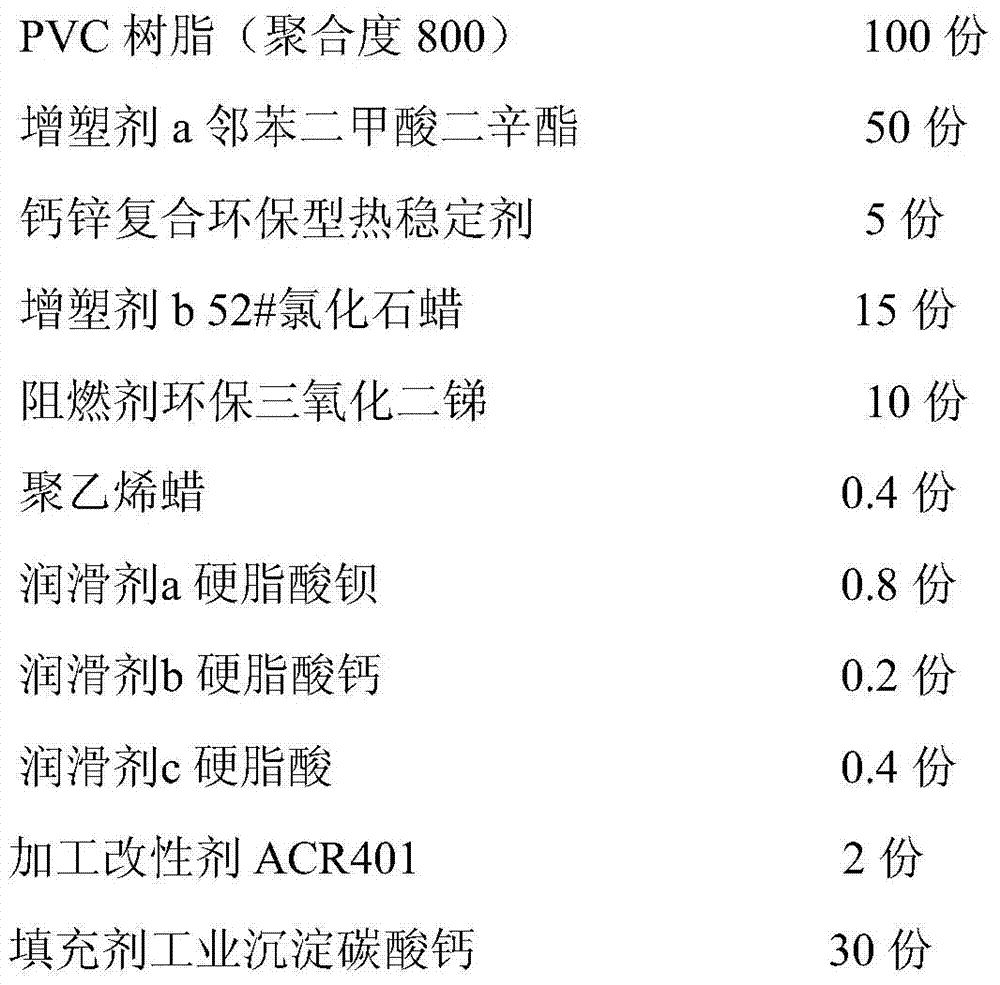

The invention relates to a flame-retardant PVC injection molding material for a branch cable. The flame-retardant PVC injection molding material comprises the following raw materials by weight: 90 to 100 parts of PVC resin, 30 to 60 parts of a plasticizer a, 15 to 25 parts of a plasticizer b, 4 to 8 parts of a heat stabilizer, 8 to 15 parts of a fire retardant, 0.2 to 0.4 part of polyethylene wax, 0.5 to 1 part of a lubricant a, 0.2 to 0.5 part of a lubricant b, 0.3 to 0.8 part of a lubricant c, 2 to 3 parts of a processing modifier and 20 to 50 parts of a filler. The injection molding material has excellent injection molding performance, excellent flame retardation effect and low production cost; and an injection molding product has smooth and fine surface, and the temperature resistance grade of the product reaches 70 to 90 DEG C.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

A phosphorus-free, fluorine-free, and heavy-metal-free environmental-friendly coating agent made of bio-inositol, its preparation method and application

ActiveCN104894550BImprove wettabilityStrong adhesionMetallic material coating processesOrganic acidHazardous substance

The invention relates to a novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent prepared from biological inositol and a preparation method and application of the novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent. The novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent is prepared from the biological inositol and polybasic organic acid in the mol ratio of (1:1)-(1:10). The novel non-phosphorus, fluoride-free and heavy-metal-free environmental-friendly coating film agent has the advantages that the prepared coating film agent is free from phosphorus, fluoride and heavy metal and is truly environmental-friendly; the coating film agent is high in anti-rust performance, excellent in coupling force and adhesive force for molding powder and paint, low in investment and using requirement, applicable to different kinds of metal, high in adhesive force, and capable of meeting the ROHS (Restriction of the use of certain Hazardous Substances) compliant and solving the problems of high fluorine content, poor stability during use, complexity in operation and control and the like of an existing non-phosphorus coating film agent fundamentally.

Owner:南京金环生物技术有限公司

Low-smoke halogen-free flame-retardant fireproof electronic computer cable

InactiveCN104867582AImprove securityExtended service lifeInsulated cablesInsulated conductorsLow smoke zero halogenPolyester

A low-smoke halogen-free flame-retardant fireproof electronic computer cable disclosed by the present invention comprises a cable inner core and a cable outer layer. The cable inner core is formed by extruding a polyester tape and a separately shielding aluminum plastic compound tape on an insulating power wire core from inside to outside, the insulating power wire core is formed by extruding a polyethylene insulating layer on a conductor, and a ground wire is arranged in the separately shielding aluminum plastic compound tape. A flame-retardant netted filling tape, a PP wrapping tape lining layer, a total shielding aluminum plastic compound tape and a low-smoke halogen-free flame-retardant fireproof sheath layer containing a ground wire are extruded on the cable outer layer orderly from inside to outside. The cable of the present invention does not release a harmful gas and the smog when burning, does not cause a secondary disaster, is high in safety, is environment friendly, has no pollution, can be laid in various specific occasions, enables the service life of a product to be prolonged, and accords with an european union ROHS standard, thereby meeting the design requirements of being innovative in science and technology, being green environmental protection, being safe and having no pollution.

Owner:安徽华电线缆集团有限公司

High-voltage resistant cable sheath material and preparation method thereof

InactiveCN109181068ADoes not affect flame retardancyImprove insulation performancePlastic/resin/waxes insulatorsSlurryHigh voltage

The invention provides a high-voltage resistant cable sheath material which contains the following raw materials: 70-80 parts of metallocene polyethylene, 6-12 parts of polymethacrylate resins, 12-18parts of ethylene-vinyl acetate copolymers, 1-3 parts of expanded graphite, 4-8 parts of paraffin, 8-16 parts of a plasticizer, 2-6 parts of a lubricating agent, 8-16 parts of carbon black, 0.2-0.6 part of thiopropyl dilauryl ester, 3-6 parts of magnesium hydroxide, 2-5 parts of a heat stabilizer and 25-35 parts of modified fillers. The preparation method comprises the following steps: adding theplasticizer, magnesium hydroxide, thiopropyl dilauryl ester and modified fillers into a three-roll grinder to be ground into slurry; and kneading the slurry and the rest raw materials, and performingtwin-screw extrusion granulation. The high-voltage resistant cable sheath material has excellent insulation and flame retardant properties and high hardness.

Owner:安庆市泽烨新材料技术推广服务有限公司

Chromate-free passivation solution and preparation method thereof

InactiveCN108707884ASolve pollutionComply with ROHS standardMetallic material coating processesPhosphoric acidChemistry

The invention discloses a chromate-free passivation solution which is prepared from the following substances of, by weight, 5 to 35 percent of water-based functional siloxane oligomer, 1 to 15ML / L ofphytic acid, 1 to 20ML / L of phosphoric acid, 1 to 8g / L of zinc ion, and the balance water. The invention further provides a preparation method of the chromate-free passivation solution. The water-based functional siloxane oligomer and the phytic acid jointly form a film forming matter of a passivation film. The phosphoric acid and the zinc ion form an auxiliary forming film. The formula provided by the invention is completely free of chromium elements so as to be environmentally friendly. The chromate-free passivation solution provided by the invention can solve the problem of chromium pollution caused by current chromium passivation, and is the environment-friendly passivation solution free of any heavy metal.

Owner:ZHEJIANG KANGSHENG CO LTD

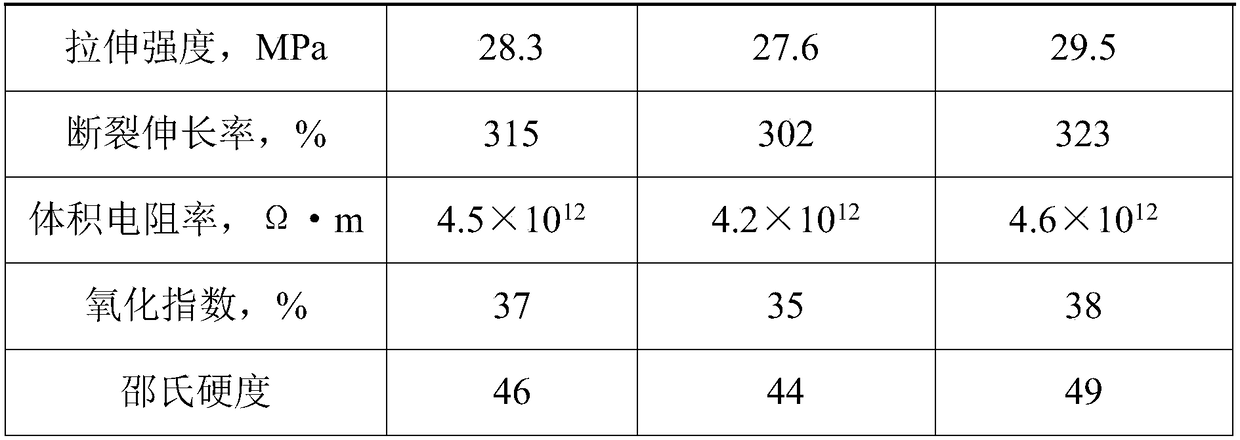

Special cable sheath material for UHV power grid system

The invention provides a cable sheath material special for an ultra-high voltage grid system. The cable sheath material is prepared from, by weight, 100-120 parts of chlorosulfonated polyethylene, 8-12 parts of ethylene-propylene-diene monomer, 20-25 parts of ethylene and ethylene-vinyl acetate copolymer, 10-20 parts of acetyl tributyl citrate, 10-15 parts of calcined clay, 1-3 parts of resorcinol bis(diphenyl phosphate), 1-2 parts of color black, 2-6 parts of inorganic hydroxide, 2-5 parts of heat stabilizer, 5-10 parts of trioctyl citrate, 0.1-0.2 part of an antioxidant, 1-2 parts of antimonous oxide, 0.2-0.4 part of polyethylene wax, 10-20 parts of tributyl citrate ester and 1-2 parts of naphthenic acid metal salt. The cable sheath material special for the ultra-high voltage grid system can be widely applied to an insulation outer sheath of an ultra-high voltage cable needing the special acid-resisting and oil-resisting environment.

Owner:STATE GRID CORP OF CHINA +1

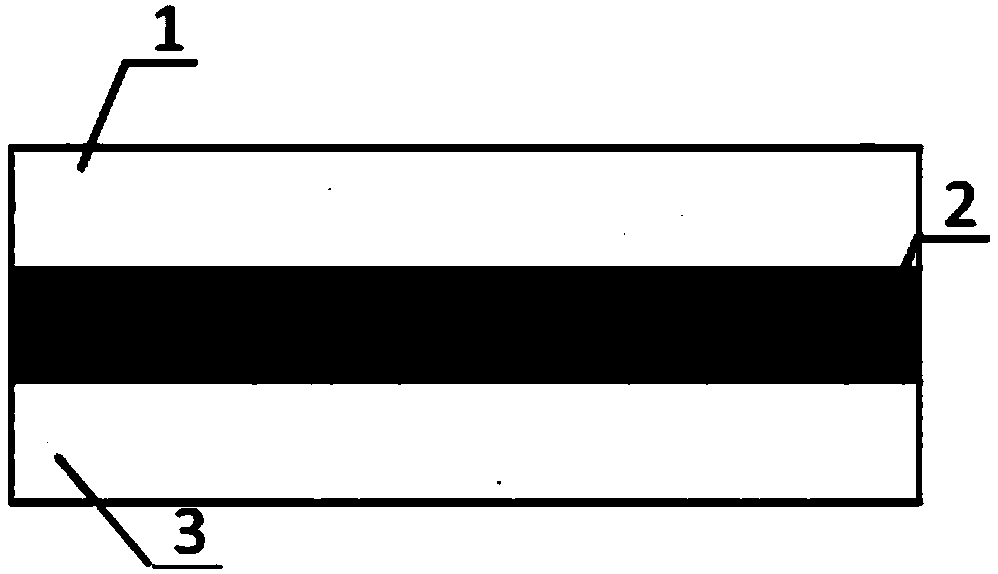

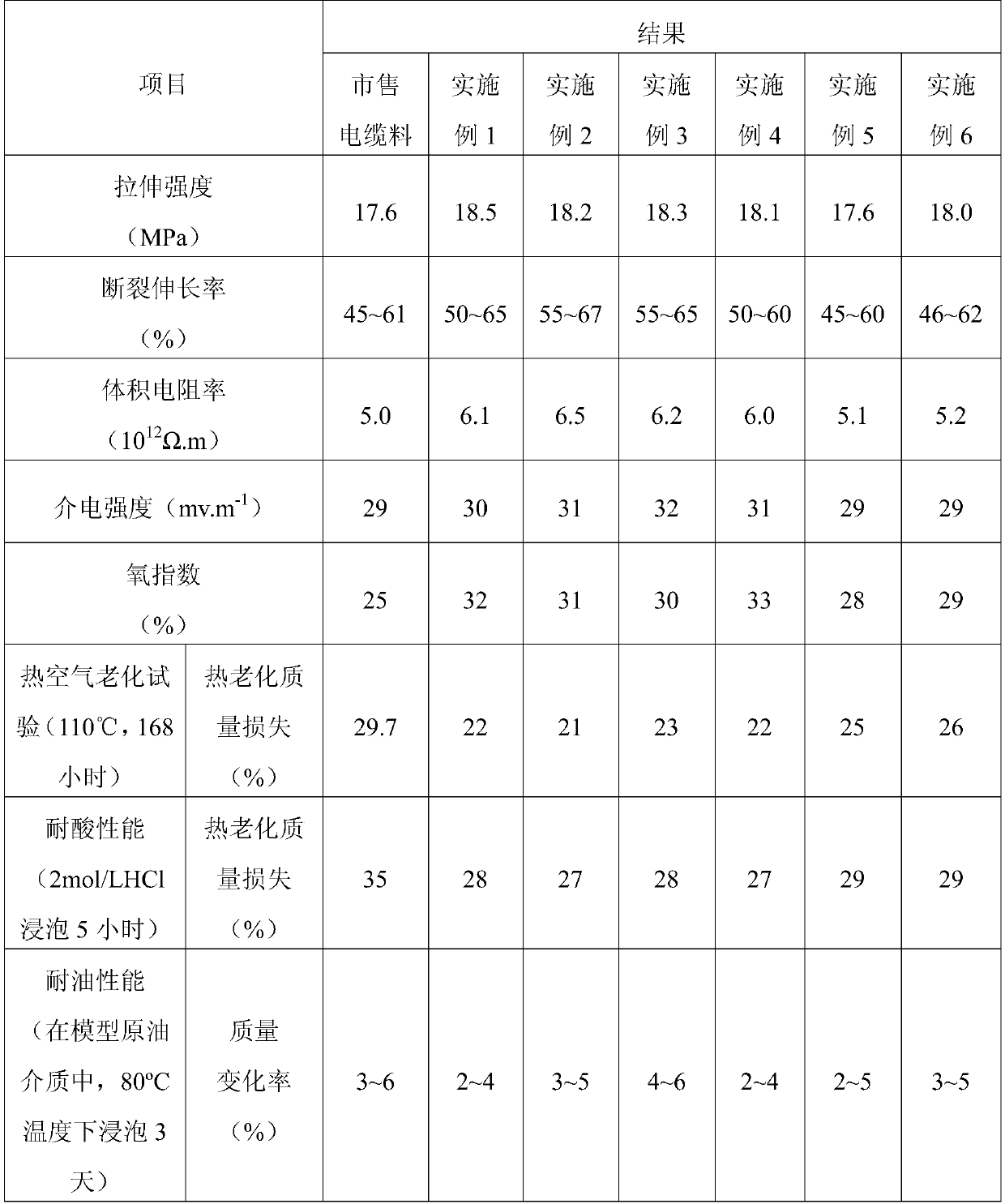

Diaphragm for nickel-cadmium battery, preparation method thereof and battery

InactiveCN101820055BGrowth inhibitionAvoid micro-short circuitCell component detailsNickel accumulatorsNickel cadmiumManganese

The invention provides a diaphragm for a nickel-cadmium battery and belongs to the field of nickel-cadmium batteries. The diaphragm comprises a base material and a manganese salt positioned in pores of the base material and / or on the surface of the base material. The invention also provides a preparation method for the diaphragm for the nickel-cadmium battery, and a nickel-cadmium secondary battery which comprises the diaphragm. The nickel-cadmium secondary battery with the diaphragm can effectively prevent cadmium dendritic crystals from growing, inhibit further growth of the cadmium dendritic crystals, improve charging efficiency in the later charging period and greatly improve slow charging cycle performance, and can be widely applied to the nickel-cadmium batteries.

Owner:BYD CO LTD

A non-fading, flame-retardant, anti-ultraviolet thermoplastic elastomer orange sheath material for AC charging piles and its preparation method

The invention discloses a non-fading, flame-retardant and anti-ultraviolet thermoplastic elastomer orange sheath material for AC charging piles and a preparation method thereof. Components comprising the following parts by weight: 50 parts of polyvinyl chloride resin A; 50 parts of polyvinyl chloride resin B; 43-66 parts of plasticizer; 20-40 parts of nanometer calcium carbonate; 3-6 parts of white carbon black; 4-8 parts of stabilizer; 0.2-0.8 parts of light stabilizer; 1-4 parts of ultraviolet absorber; 3-6 parts of environmentally friendly antimony trioxide; 2-3 parts of processing modification additives; ‑1 serving. The non-fading, flame-retardant and UV-resistant thermoplastic elastomer orange sheath material for AC charging piles of the present invention can be applied to EV-VV and EV-VVPV cables specified in the CQC1103-2014 standard.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Cadmium negative pole, preparation method thereof and secondary nickel-cadmium battery containing same

InactiveCN101609889BIncreased initial capacity playImprove consistencyAlkaline accumulator electrodesNickel accumulatorsElectrical batteryAdhesive

The invention relates to a cadmium negative pole used for a secondary nickel-cadmium battery. The cadmium negative pole comprises a current collector and a negative pole material covered on the current collector, and the negative pole material contains a negative pole active substance and negative pole adhesive, wherein the negative pole material also contains a conductive metallic oxide which contains at least two metallic elements. The growth of cadmium dendritic crystals of a battery prepared by adopting the cadmium negative pole is effectively restrained in a charging process, thereby better meeting the requirements on the low-current charge and the high-current discharge of the battery.

Owner:BYD CO LTD

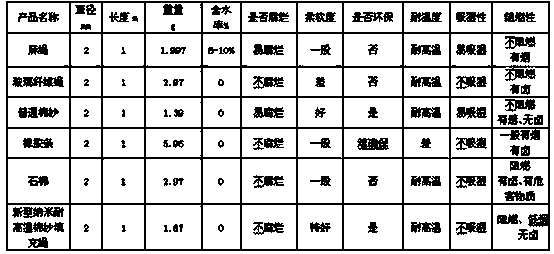

Comprehensive waterproof aluminum alloy power cable with overload resistance and high temperature resistance

InactiveCN105469869AImprove safety and reliabilityStable chemical propertiesPower cables with screens/conductive layersFlexible cablesEnvironmental resistanceBlocking layer

The invention discloses a comprehensive waterproof aluminum alloy power cable with overload resistance and high temperature resistance. The comprehensive waterproof aluminum alloy power cable comprises cable inner cores and cable outer layers wrapped outside the cable inner cores, wherein each cable inner core consists of a conducting cable core and an insulating layer of a conductor water blocking layer from inside to outside in sequence; each cable outer layer consists of a wrapping tape, a comprehensive waterproof layer and a protective jacket from inside to outside in sequence, and a water blocking filler is arranged among the cable inner cores; the insulating layer is made of a 150-DEG C halogen-free flame retardant radiation insulating material; each wrapping tape is a high-expansion water blocking wrapping tape with insulation and hygroscopicity; and the protective jacket is made of a thermoplastic protective jacket material. According to the comprehensive waterproof aluminum alloy power cable, the halogen-free flame retardant radiation insulating material is adopted because of insulation; the aluminum alloy power cable has comprehensive waterproof performance, and is resistant to heat and high temperature, large in carrying capacity, high in overload protection capacity, resistant to aging and cracking, high in bending performance, stable in electrical insulation performance, long in service life, free of hydracid gas release during combustion, non-toxic and environment-friendly, and the power cable is self-extinguished when leaving away from fire, so that the emission of toxic and corrosive gas and the generation of smoke can be greatly reduced.

Owner:SHANGHAI MORN ELECTRIC EQUIPMENT CO LTD

Silicon rubber follow-up treatment agent and preparation method thereof

InactiveCN101544819BWon't hurtPlay a bridging roleAdhesive processes with surface pretreatmentPolyesterPolymer science

The invention relates to the technical field of silicon rubber treatment agents, in particular to a silicon rubber follow-up treatment agent and a preparation method thereof. The silicon rubber follow-up treatment agent is prepared from macromolecule polyester polyol or macromolecule polyester polyether, polyol, vulcabond and latent solvent and plays a role of bridge between bond and colloid. When error adhibiting occurs, reworking is easy, i.e. acetone is directly dropped to the bonding portion to make silicon rubber bonded together to separate from each other, and the silicon rubber can notbe damaged in the peel-off process. The invention avoids waste due to the defect of the prior art and accords with the European union ROHS standard.

Owner:GUANGDONG ZHICHENG CHEM

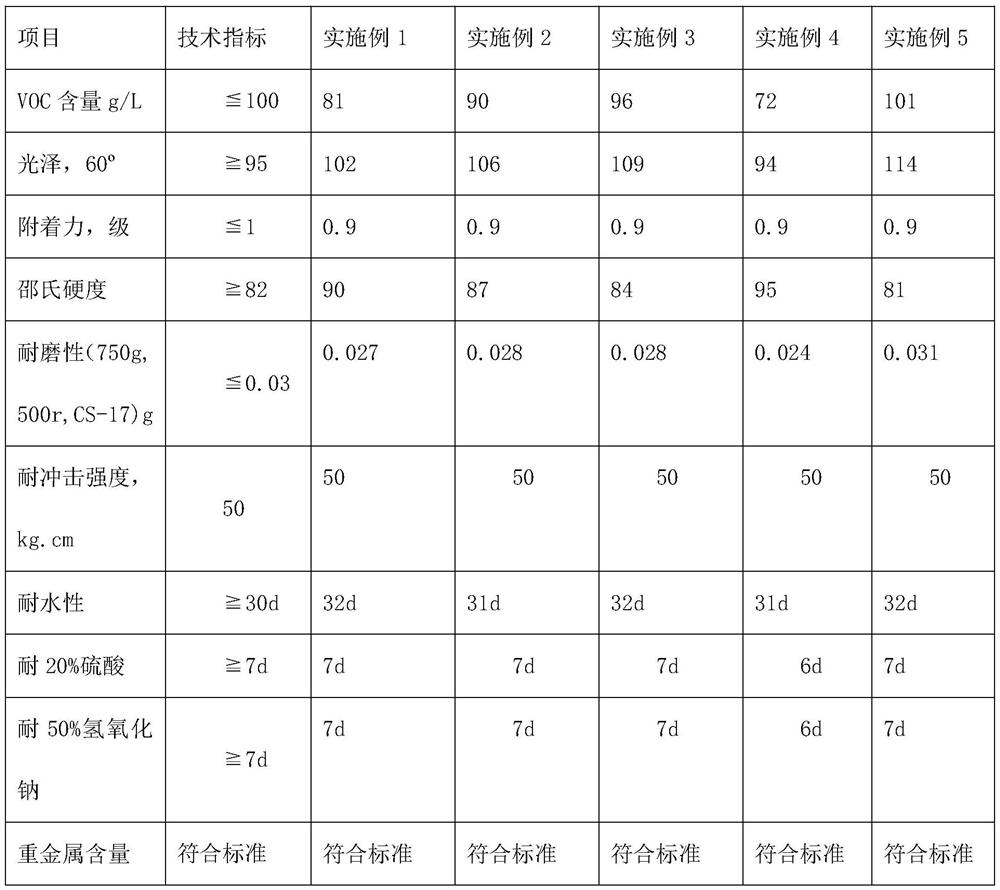

Novel environment-friendly nontoxic epoxy floor coating and preparation method thereof

InactiveCN112574639AMeet emissionsMeet environmental requirementsAntifouling/underwater paintsPaints with biocidesFirming agentReactive diluent

The invention discloses a novel environment-friendly nontoxic epoxy floor coating and a preparation method thereof. The novel environment-friendly nontoxic epoxy floor coating is prepared from a component A and a component B. During use, the two components are mixed; wherein the component A is prepared from the following synthetic raw materials in parts by weight: 40-60 parts of low-molecular-weight epoxy resin, 5-10 parts of a reactive reactive diluent, 0.5-1 part of a dispersing agent, 0.2-0.5 part of a leveling agent, 0.2-0.5 part of an antifoaming agent, 5-10 parts of an organic pigment, 40-50 parts of quartzite and 0.2-0.5 part of a wetting agent; and the component B is a modified alicyclic amine curing agent. The novel environment-friendly non-toxic epoxy floor coating meets the requirements of the market for environment and environmental protection, meets VOC emission, meets the European Union ROHS standard, and is high in decoration, high in corrosion resistance, environmentally friendly, non-toxic and suitable for large-scale application and popularization.

Owner:湖北富莱德力高涂料股份有限公司

Spraying coating material

InactiveCN101250356BSimple processEasy to operateLiquid surface applicatorsCellulose coatingsCelluloseSpray coating

The invention discloses spray plating paint, which comprises components with percentage by weight of 10-22 wt% cellulose resin, 6-12 wt% vinyl chloride-acetate copolymer, 0.25-05 wt% micro-molecular directing auxiliary agent, 1.5-4.0 wt% silver slurry and 61.5-82.3 wt% solvent. The spray plating effect of the paint is same as electroplating products, the paint can be used on various plastic adhesive electric products such as ABS, PC, PC+ ABS and the like, and the spraying technology is simple and can be operated conveniently.

Owner:HUIZHOU CHANGRUNFA PAINT

Flame retardant curing solution and technology for manufacturing halogen free nanometer high temperature resistant cotton yarn filling rope by utilizing same

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

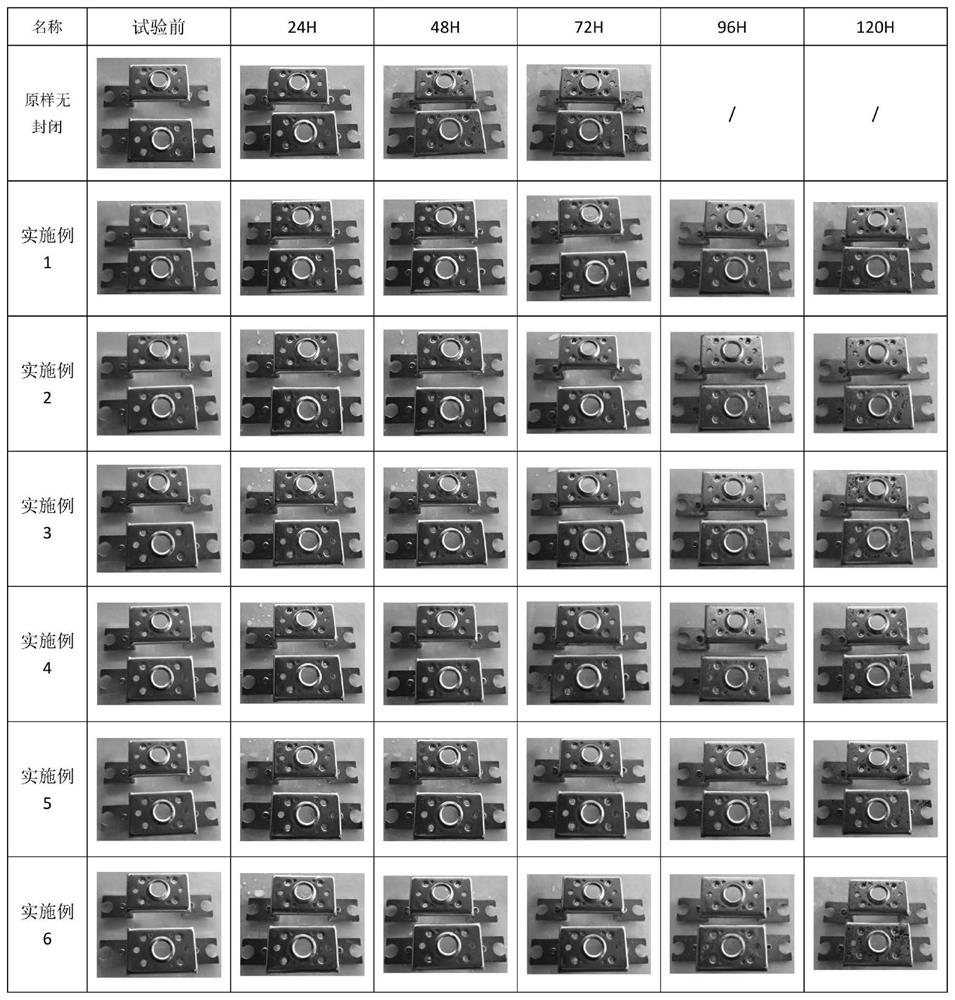

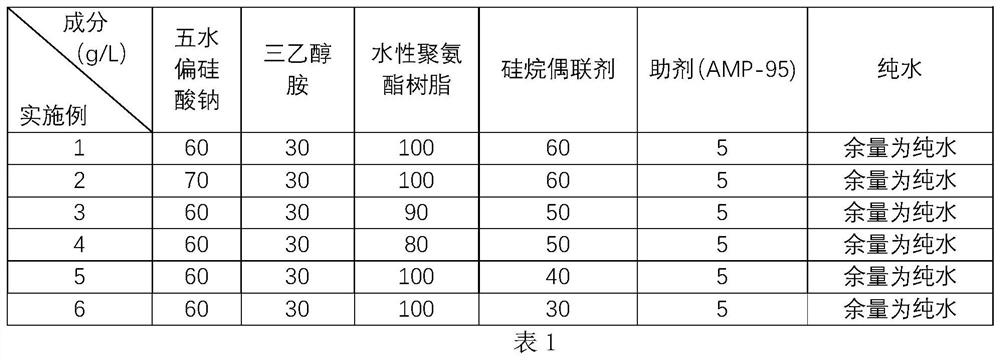

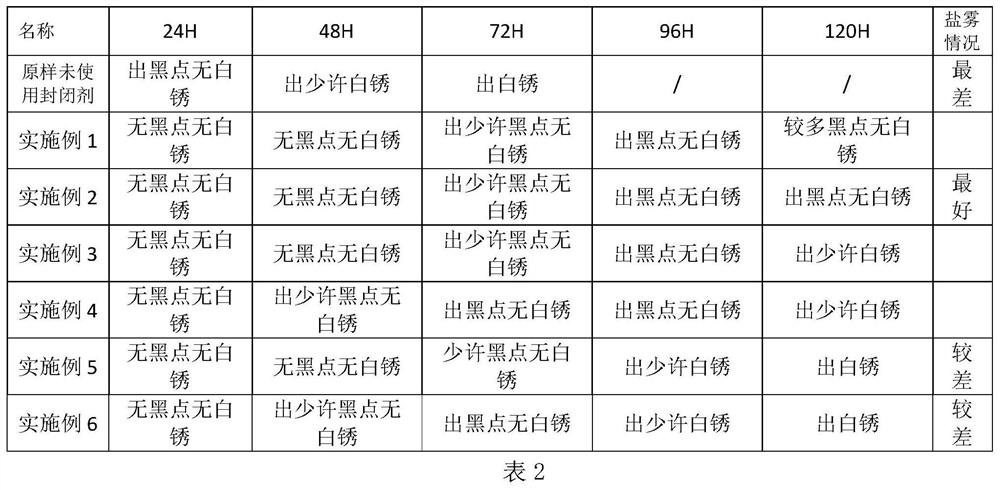

Composite zinc coating sealing agent with excellent scratch resistance and preparation method thereof

InactiveCN111826069AImprove corrosion resistanceImprove scratch resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceSodium metasilicate

The invention discloses a composite zinc coating sealing agent with excellent scratch resistance. The composite zinc coating sealing agent is prepared from the following raw materials in parts by weight and volume: 10 g / L to 200 g / L of sodium metasilicate pentahydrate, 5 g / L to 100 g / L of triethanolamine, 50 g / L to 300 g / L of waterborne polyurethane resin, 10 g / L to 200 g / L of a silane coupling agent and 0.5 g / L to 50 g / L of auxiliaries. The sealing agent has excellent scratch resistance and corrosion resistance. The invention further provides a preparation method of the sealing agent.

Owner:江门市高信科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com