High-insulation shielding wrapping tape and preparation method thereof

A high insulation and taping technology, applied in the direction of insulated conductors, insulated cables, chemical instruments and methods, etc., can solve the problems of no insulating protective layer, shielding tape is easy to conduct electricity, electric shock, etc., and achieves the effect of strong temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 The preparation method of high insulation shielding tape

[0022] 1) Use high elastic insulating cloth made of functional composite fibers; use polyester filament 50-150dtex for warp yarn, density 30-40 threads / cm, choose medium alkali or alkali-free weft yarn, 45 double strands or 21-33 single strands Silk, density 10-20 / cm.

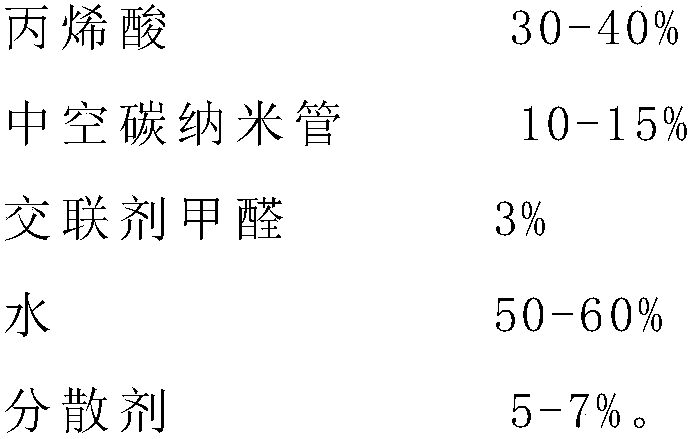

[0023] 2) Use polymerization technology to make high-viscosity conductive composite binder: mainly use nano-conductive hollow carbon nanotubes and water-based acrylic emulsion, add cross-linking agent, dispersant and water, stir at high speed under normal temperature and high pressure conditions, that is A binder is obtained; the composition and percentage of the binder are: 30% of acrylic acid, 10% of hollow carbon nanotubes, 3% of crosslinking agent formaldehyde, 50% of water, and 7% of dispersant.

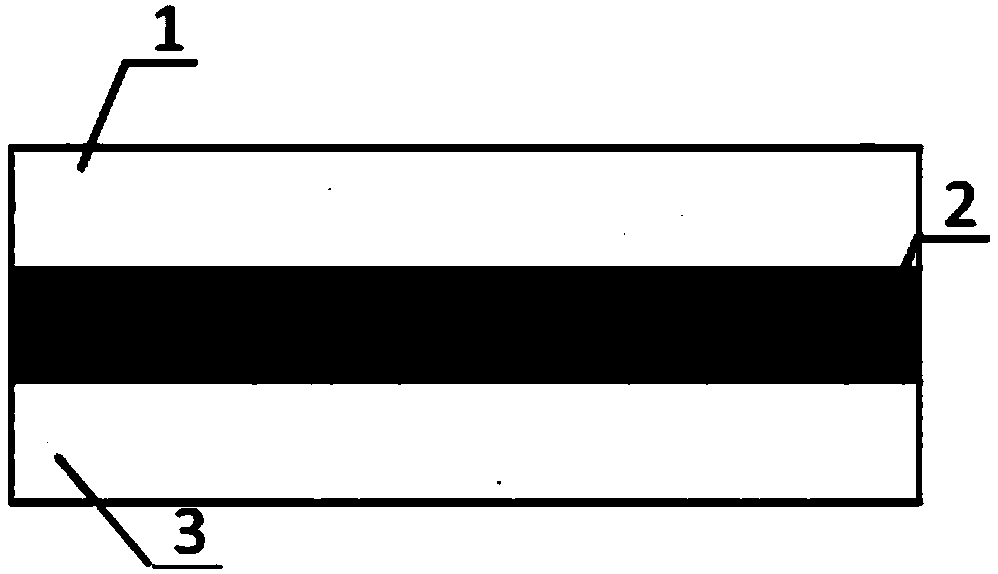

[0024] 3) High-speed dry laminating machine and foam spraying glue coating technology are used to compound high-elastic insulating c...

Embodiment 2

[0026] Embodiment 2 The preparation method of high insulation shielding tape

[0027] 1) Use high elastic insulating cloth made of functional composite fibers; use polyester filament 50-150dtex for warp yarn, density 30-40 threads / cm, choose medium alkali or alkali-free weft yarn, 45 double strands or 21-33 single strands Silk, density 10-20 / cm.

[0028] 2) Use polymerization technology to make high-viscosity conductive composite binder: mainly use nano-conductive hollow carbon nanotubes and water-based acrylic emulsion, add cross-linking agent, dispersant and water, stir at high speed under normal temperature and high pressure conditions, that is A binder is obtained; the composition and percentage of the obtained binder are: 30% of acrylic acid, 10% of hollow carbon nanotubes, 3% of crosslinking agent formaldehyde, 52% of water, and 5% of dispersant.

[0029] 3) High-speed dry laminating machine and foam spraying glue coating technology are used to compound high-elastic ins...

Embodiment 3

[0031] Embodiment 3 The preparation method of high insulation shielding tape

[0032] 1) Use high elastic insulating cloth made of functional composite fibers; use polyester filament 50-150dtex for warp yarn, density 30-40 threads / cm, choose medium alkali or alkali-free weft yarn, 45 double strands or 21-33 single strands Silk, density 10-20 / cm.

[0033] 2) Use polymerization technology to make high-viscosity conductive composite binder: mainly use nano-conductive hollow carbon nanotubes and water-based acrylic emulsion, add cross-linking agent, dispersant and water, stir at high speed under normal temperature and high pressure conditions, that is A binder is obtained; the composition and percentage of the binder are: 30% of acrylic acid, 12% of hollow carbon nanotubes, 3% of crosslinking agent formaldehyde, 50% of water, and 5% of dispersant.

[0034] 3) High-speed dry laminating machine and foam spraying glue coating technology are used to compound high-elastic insulating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com