A non-fading, flame-retardant, anti-ultraviolet thermoplastic elastomer orange sheath material for AC charging piles and its preparation method

A thermoplastic elastomer and anti-ultraviolet technology, which is applied in the field of cable sheathing materials, can solve the problems of cable aging, easy fading, and affecting the appearance of cables, and achieve the effect of high cost performance and great price advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

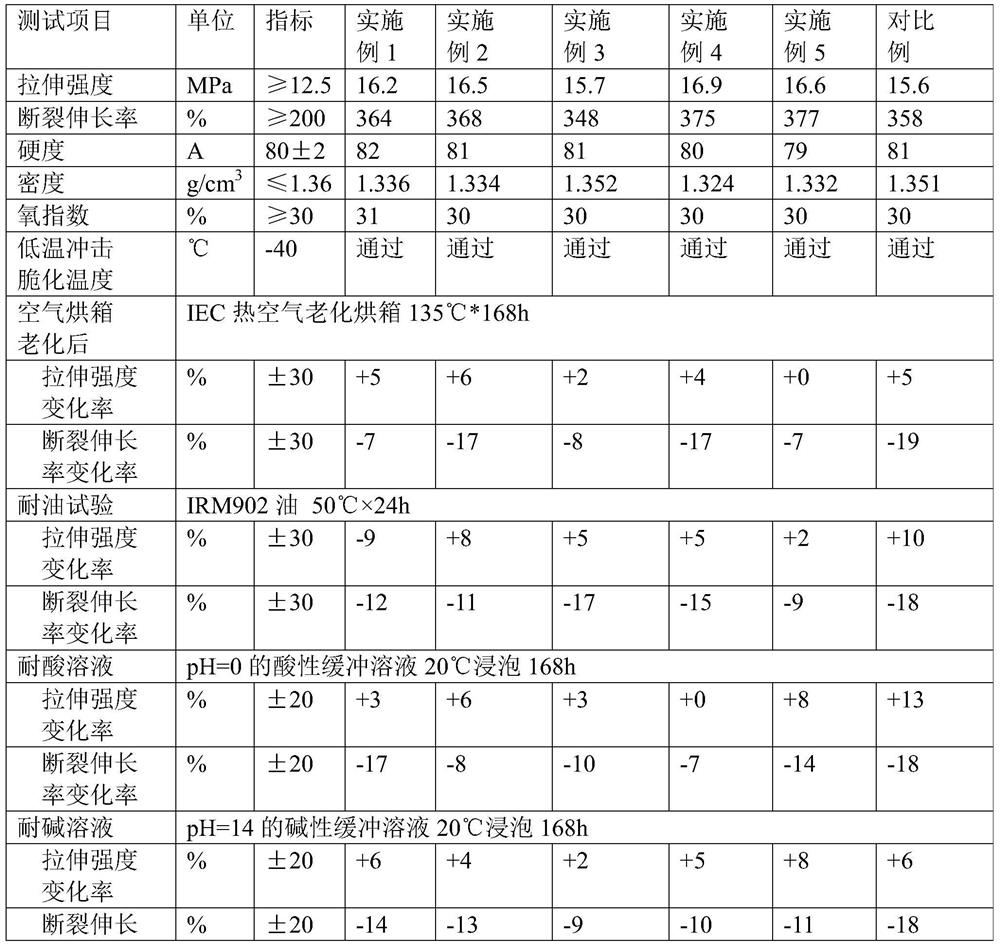

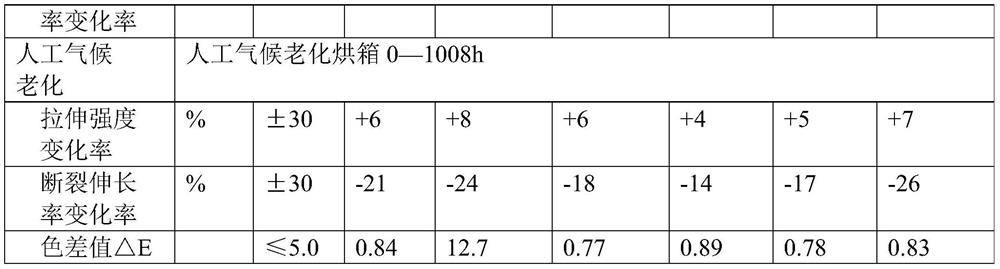

Examples

Embodiment 1

[0039] 1. Experimental materials

[0040] 50 parts of polyvinyl chloride resin A (TPH-31); 50 parts of polyvinyl chloride resin B (S-65); 30 parts of plasticizer diisoundecyl phthalate; 15 parts of plasticizer adipic acid polyester 5 parts of plasticizer dioctyl adipate; 10 parts of nano-calcium carbonate; 5 parts of white carbon black (R972); 6 parts of environmentally friendly calcium-zinc composite stabilizer (MC91660KA); 0.5 part of light stabilizer (944); 2 parts of ultraviolet absorber (UV531); 5 parts of antimony trioxide; 2.5 parts of processing modifier (P551A); non-fading pigment powder: K2915 red 0.15 part, H10G yellow 0.25 part and R902 titanium dioxide: 0.4 part.

[0041] 2. Preparation method:

[0042] a, 50 kilograms of polyvinyl chloride resin A (TPH-31), 50 kilograms of polyvinyl chloride resin B (S-65), 30 kilograms of plasticizer diisoundecyl phthalate; plasticizer adipic acid 15 kg of polyester; 5 kg of plasticizer dioctyl adipate; 10 kg of nano-calcium c...

Embodiment 2

[0046] 1. Experimental materials

[0047]50 parts of polyvinyl chloride resin A (TPH-31); 50 parts of polyvinyl chloride resin B (S-65); 30 parts of plasticizer diisoundecyl phthalate; 15 parts of plasticizer adipic acid polyester 5 parts of plasticizer dioctyl adipate; 10 parts of nano-calcium carbonate; 5 parts of white carbon black (R972); 6 parts of environmentally friendly calcium-zinc composite stabilizer (MC91660KA); 0.5 part of light stabilizer (944); 2 parts of ultraviolet absorber (UV531); 5 parts of antimony trioxide; 2.5 parts of processing modifier (P551A); ordinary pigment powder: 0.15 parts of red pigment powder (sunfast red), yellow pigment powder (HR-2 yellow ) 0.25 parts and titanium dioxide: 0.4 parts. 2. Preparation method:

[0048] a, 50 kilograms of polyvinyl chloride resin A (TPH-31), 50 kilograms of polyvinyl chloride resin B (S-65), 30 kilograms of plasticizer diisoundecyl phthalate; plasticizer adipic acid 15 kg of polyester; 5 kg of plasticizer di...

Embodiment 3

[0052] 1. Experimental materials

[0053] 50 parts of polyvinyl chloride resin A (TPH-31); 50 parts of polyvinyl chloride resin B (S-65); 30 parts of plasticizer diisoundecyl phthalate; 15 parts of plasticizer adipic acid polyester 5 parts of plasticizer dioctyl adipate; 15 parts of nano-calcium carbonate; 3 parts of white carbon black (R972); 7 parts of environment-friendly calcium-zinc composite stabilizer (MC91660KA); 0.8 part of light stabilizer (944); 1.2 parts of ultraviolet absorber (UV531); 4 parts of antimony trioxide; 2 parts of processing modifier (P551A); non-fading pigment powder: K3690 red 0.15 part, K1090 yellow 0.25 part and R902 titanium dioxide: 0.4 part.

[0054] 2. Preparation method:

[0055] a, 50 kilograms of polyvinyl chloride resin A (TPH-31), 50 kilograms of polyvinyl chloride resin B (S-65), 30 kilograms of plasticizer diisoundecyl phthalate; plasticizer adipic acid 15 kg of polyester; 5 kg of plasticizer dioctyl adipate; 15 kg of nano-calcium carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com