Composite zinc coating sealing agent with excellent scratch resistance and preparation method thereof

A scratch-resistant, composite technology, used in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor salt spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

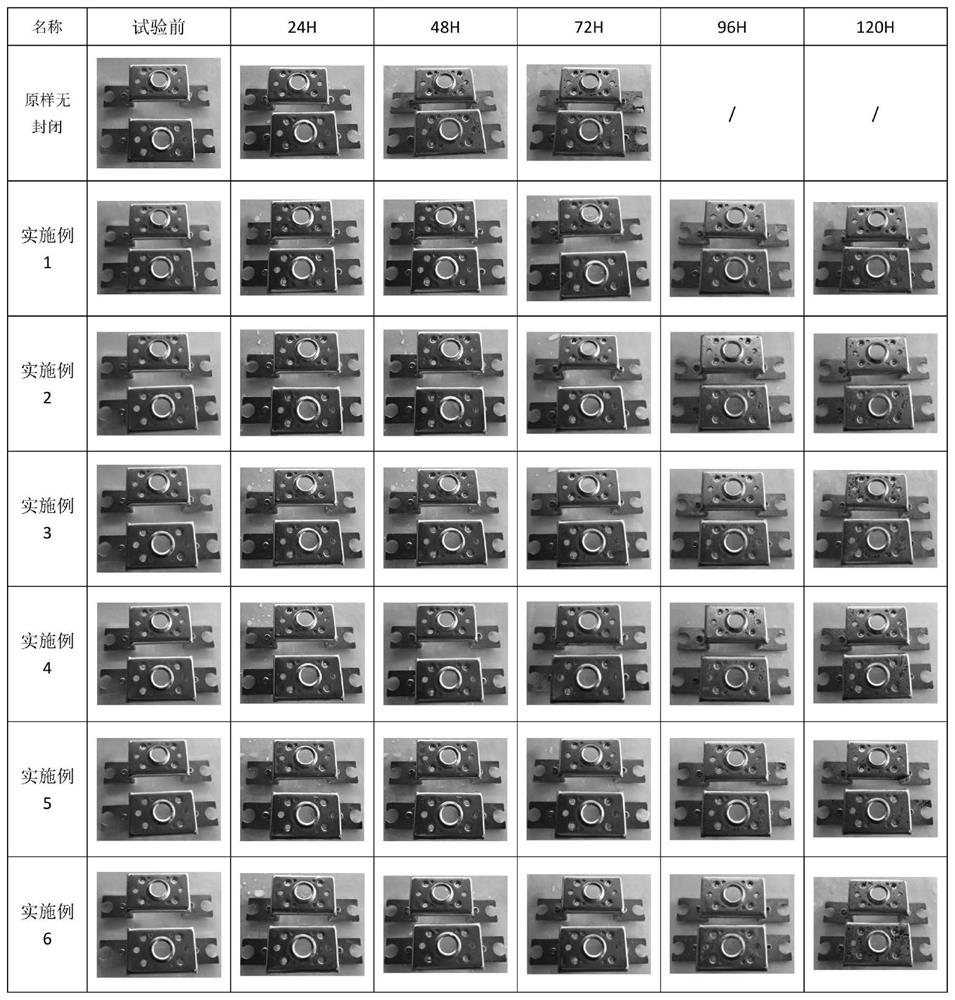

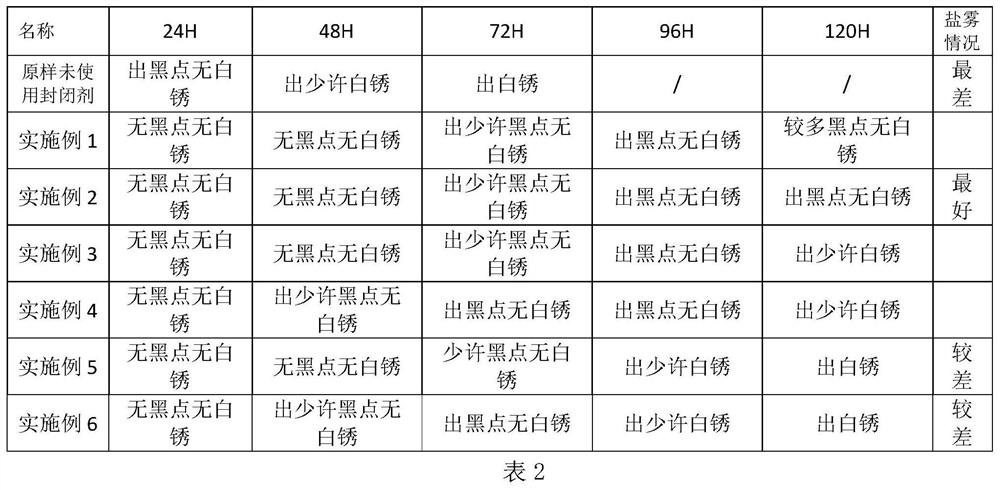

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

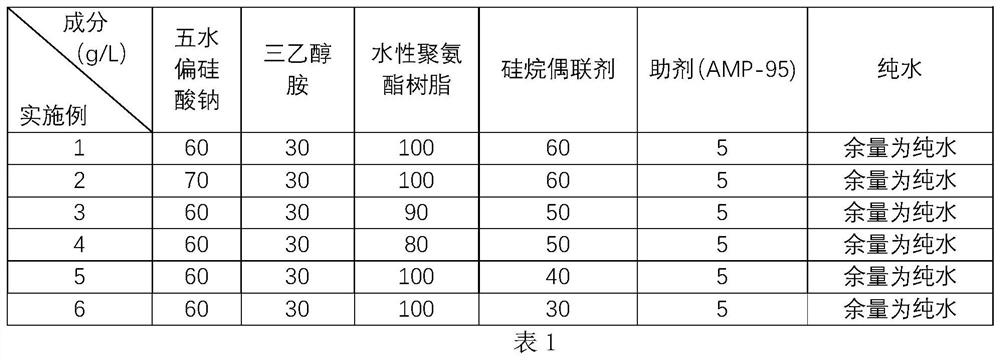

[0025] Composite galvanized layer sealant with excellent scratch resistance, the parts by weight of each component are: sodium metasilicate pentahydrate 10-200g / L, triethanolamine 5-100g / L, water-based polyurethane resin 50-300g / L , silane coupling agent 10-200g / L, additive 0.5-50g / L, sodium metasilicate pentahydrate will re-dissolve a small part after contact with water after being bruised, and can fill the bruised part after dissolution and regenerate Repair the bruised position, when the silane coupling agent encounters water at the bruised position, the part of the coupling agent that has not been hydrolyzed in the previous process will be hydrolyzed, and the surface of the zinc layer at the scratched position will be re-crosslinked to form a film. To repair the role, to achieve self-healing, thereby improving corrosion resistance and sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com