Highly corrosion-resistant zinc coating sealing agent

A galvanized layer, high corrosion resistance technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of poor salt spray performance of the coating, sticking tools, etc., to achieve excellent environmental performance, convenient production control, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

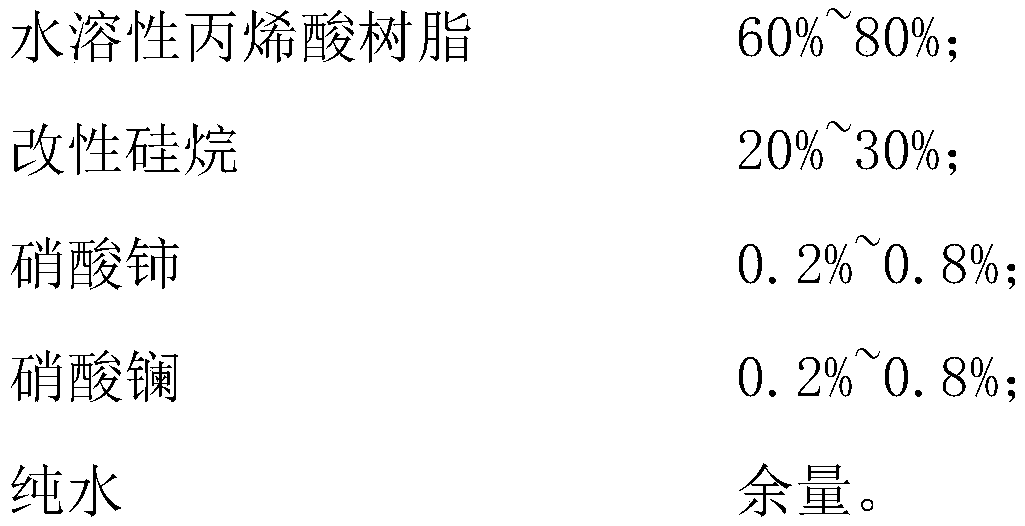

Embodiment 1

[0031] (1) First add 4.4 parts of pure water to the container, add 0.8 part of cerium nitrate and 0.8 part of lanthanum nitrate at a rotating speed of 150 rpm, until completely dissolved;

[0032] (2) Add 60% water-soluble acrylic resin in the stirring tank, and slowly add the dissolving solution obtained in step (1) at a speed of 120 rpm until uniformly stirred;

[0033] (3) Add 30 parts of polyethylene glycol-14 dimethylsiloxane into the stirring tank at a rotating speed of 100 rpm until it is evenly stirred.

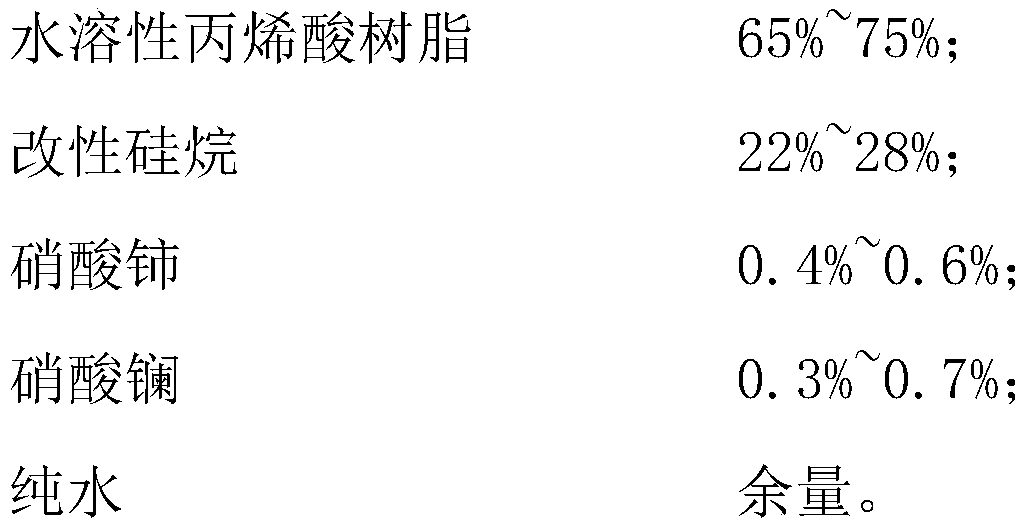

Embodiment 2

[0035] (1) First add 3.6 parts of pure water to the container, and add 0.2 part of cerium nitrate and 0.2 part of lanthanum nitrate at a speed of 150 rpm until the dissolution is complete;

[0036] (2) Add 76 water-soluble acrylic resins in the stirring tank, and slowly add the dissolving solution obtained in step (1) at a speed of 120 rpm until uniformly stirred;

[0037] (3) Add 20 parts of polyethylene glycol / polypropylene glycol-14 / 4-dimethylsiloxane into the stirring tank at a rotational speed of 100 rpm until it is evenly stirred.

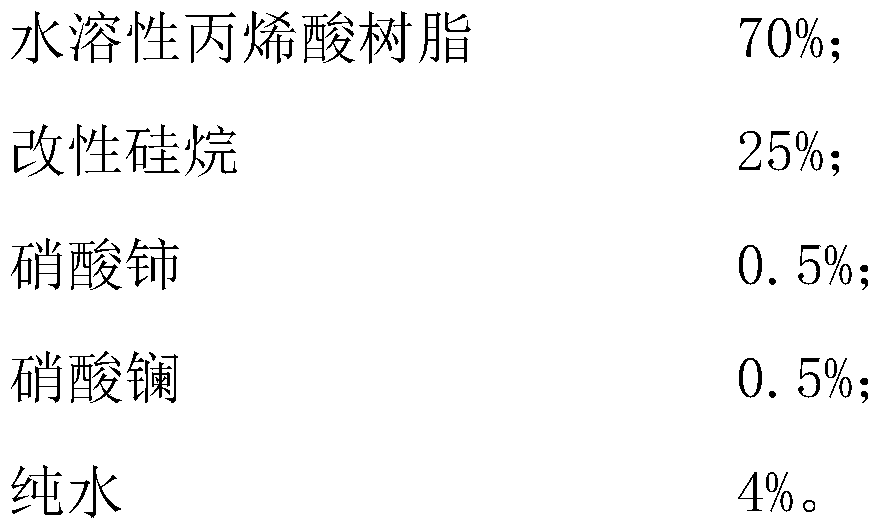

Embodiment 3

[0039] (1) First add 3.8 parts of pure water to the container, and add 0.6 part of cerium nitrate and 0.6 part of lanthanum nitrate at a speed of 150 rpm until completely dissolved;

[0040] (2) Add 70% of water-soluble acrylic resin in the stirring tank, and slowly add the solution obtained in step (1) at a speed of 120 rpm until uniformly stirred;

[0041] (3) Add 25 parts of polyethylene glycol-6 acetate siloxane into the stirring tank at a rotational speed of 100 rpm, until it is evenly stirred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com