Water-based single-component high-corrosion-resistance primer-topcoat paint and preparation method of water-based single-component high-corrosion-resistance primer-topcoat paint

A single-component, water-based technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as long construction period, complicated coating process, poor surface smoothness, etc., and achieves convenient preparation, improved performance indicators, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The water-based one-component high anticorrosion bottom-surface all-in-one paint of the present embodiment comprises: 55 parts of water-based carbon-titanium hyperbranched silicone acrylic resin, 0.6 part of cosolvent, 13.4 parts of distilled water, 0.2 part of pH regulator, 0.1 part of defoamer, dispersant 1 part, 1.6 parts of coalescent additive, 0.6 part of anti-flash rust additive, 6.5 parts of antirust pigment, 15 parts of pigment, 5 parts of filler, 0.5 part of thickener I, and 0.5 part of thickener II.

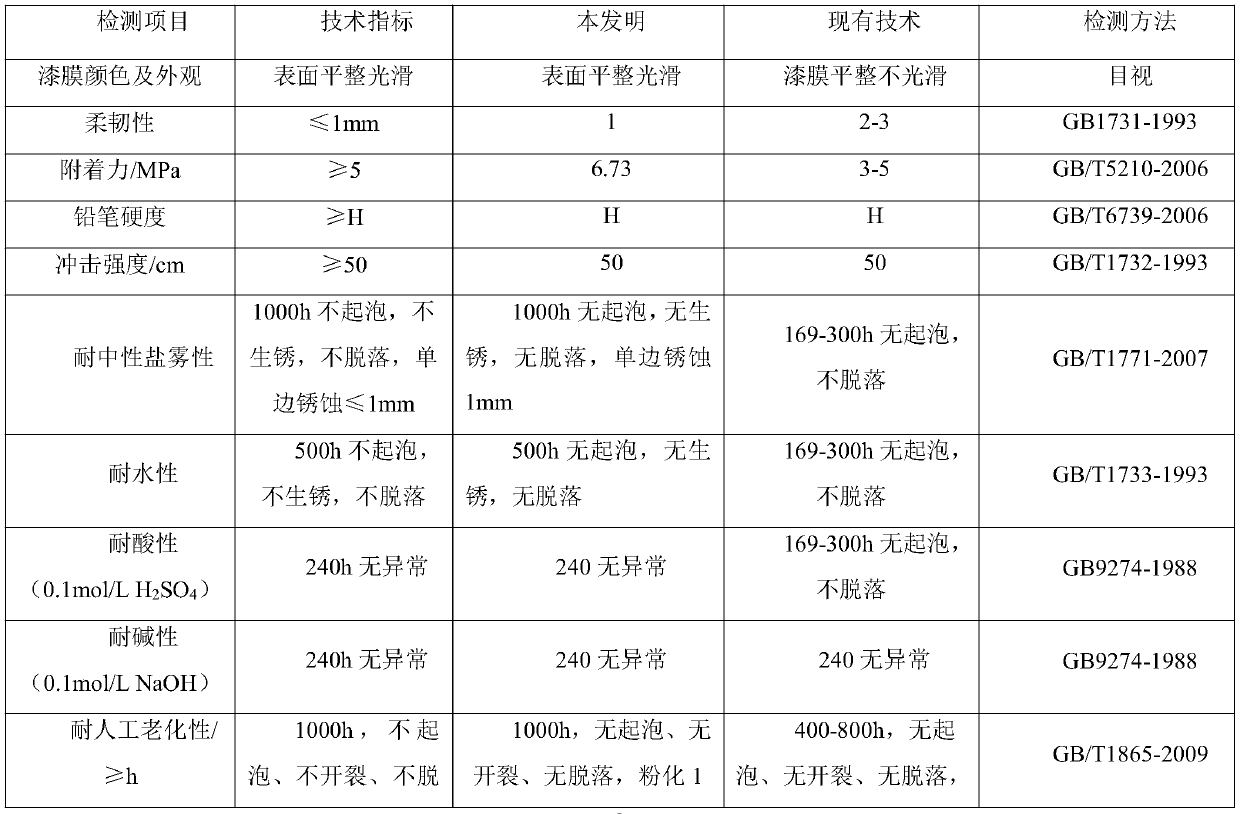

[0020] Adjust to the appropriate viscosity with water, spray the board, and maintain. The measured technical indicators are shown in Table 1:

[0021]

[0022]

[0023] Table 1 Product Performance Results Table

Embodiment 2

[0025] The water-based one-component high anticorrosion bottom and surface all-in-one paint of the present embodiment comprises:

[0026] 50 parts of water-based carbon-titanium hyperbranched silicone acrylic resin, 0.6 parts of co-solvent, 18.5 parts of distilled water, 0.2 parts of pH regulator, 0.1 part of defoamer, 1 part of dispersant, 1.5 parts of film-forming aid, 0.6 part of anti-flash rust additive 6.5 parts of antirust pigment, 15 parts of pigment, 5 parts of filler, 0.5 part of thickener I, and 0.5 part of thickener II.

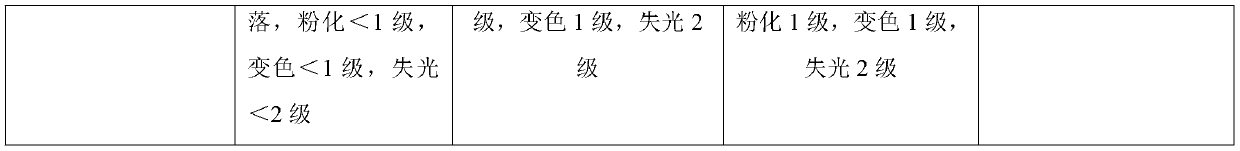

[0027] In this embodiment, the water is adjusted to a suitable viscosity, the plate is sprayed, and the maintenance is carried out. The technical indicators measured are shown in Table 2:

[0028]

[0029]

[0030] Table 2 Product Performance Results Table

Embodiment 3

[0032] The water-based one-component high anticorrosion bottom-surface all-in-one paint of the present embodiment comprises: 55 parts of water-based carbon-titanium hyperbranched silicone acrylic resin, 0.6 part of cosolvent, 13.4 parts of distilled water, 0.2 part of pH regulator, 0.1 part of defoamer, dispersant 1 part, 1.6 parts of coalescent additive, 0.5 part of anti-flash rust additive, 3.5 parts of antirust pigment, 15 parts of pigment, 8.1 part of filler, 0.5 part of thickener I, and 0.5 part of thickener II.

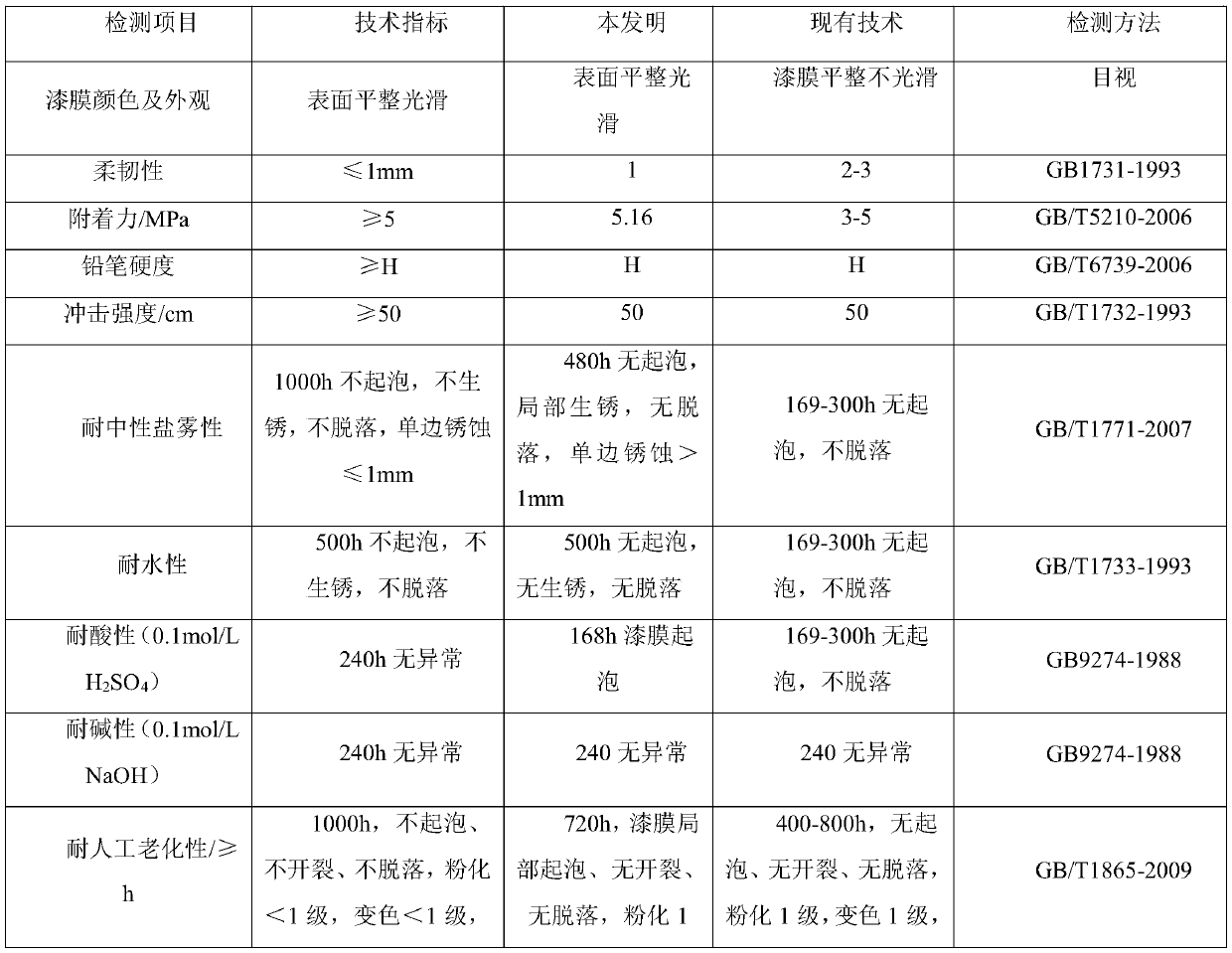

[0033] In this embodiment, the water is adjusted to a suitable viscosity, the plate is sprayed, and the maintenance is carried out. The technical indicators measured are shown in Table 3:

[0034]

[0035]

[0036] Table 3 product performance result table

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com