Waterborne coating structure coating layer with high salt spray resistance

A water-based coating, salt spray-resistant technology, applied in coatings, anti-corrosion coatings, devices for coating liquids on surfaces, etc. Salt spray performance, small thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

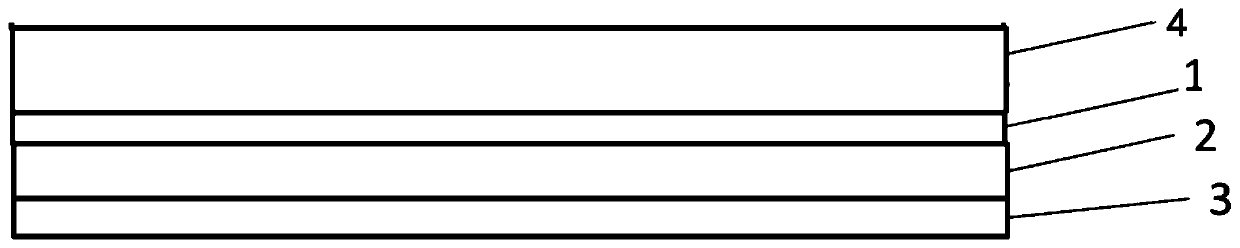

[0060] 1.1 A water-based paint structural coating with high salt spray resistance, the water-based paint structural coating includes:

[0061] The silane film coated on the iron sheet substrate, this silane is mercaptopropyltrimethoxysilane, its thickness is 50nm,

[0062] Coating the chromium-free zinc-aluminum coating on the above-mentioned silane film, the coating liquid used to form the chromium-free zinc-aluminum coating is composed of the following components by weight: 25 parts of zinc powder, 5 parts of aluminum powder, wetting and dispersing 22 parts of agent PEG2000, 2 parts of passivating agent sodium phosphomolybdate, 3 parts of corrosion inhibitor sodium molybdate, 26 parts of water, 7 parts of film-forming agent KH560 and 0.8 part of thickener hydroxyethyl cellulose, the thickness of which is 3 μm, and

[0063] The silane film coated on the chrome-free zinc-aluminum coating, the silane is mercaptopropyltrimethoxysilane, has a thickness of 50 nm.

[0064] 1.2 Th...

Embodiment 2

[0073] 2.1 A water-based paint structural coating with high salt spray resistance, the water-based paint structural coating includes:

[0074] The silane film that is coated on the iron sheet substrate, this silane is two-[3-(triethoxy silicon)-propyl]-tetrasulfide, the thickness of this silane film is 80nm,

[0075] Coating the chromium-free zinc-aluminum coating on the above-mentioned silane film, the coating liquid used to form the chromium-free zinc-aluminum coating is composed of the following components by weight: 25 parts of zinc powder, 5 parts of aluminum powder, wetting and dispersing 22 parts of PEG2000 agent, 2 parts of passivating agent sodium phosphomolybdate, 3 parts of corrosion inhibitor sodium molybdate, 26 parts of water, 7 parts of film forming agent KH560 and 0.8 part of thickener hydroxyethyl cellulose. The thickness of the coating is 5 μm, and

[0076] A silane film coated on the chrome-free zinc-aluminum coating, the silane is 3-aminopropyltriethoxysil...

Embodiment 3

[0088] The water-based paint structural coating prepared by the above-mentioned examples and comparative examples is tested for corrosion resistance under the following conditions: test by GB / T10125: sodium chloride mass concentration: (5 ± 0.5)%, pH value is 6.5~7.2 , the amount of fog falling is 1~2mL / (h·cm 2 ), the nozzle pressure is 78.5~137.3kPa (0.8~1.4kgf / cm 2 ). The corrosion resistance performance obtained from the test is shown in Table 1.

[0089] Table 1:

[0090] Example

[0091] It can be seen from Table 1 that the structural coating formed by sequentially coating silane film, chromium-free zinc-aluminum coating and silane film on the iron sheet substrate can achieve neutral salt spray resistance much longer than that of the single coating on the iron sheet substrate. The sum of the neutral salt spray resistance time achieved when a single layer of chromium-free zinc-aluminum coating is coated on a layer of silane film and an iron sheet substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com