An environment-friendly two-component waterborne epoxy zinc-rich special coating composition and its preparation method

A water-based epoxy zinc-rich, coating composition technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problem of poor resistance to neutral salt spray and salt water, foaming, weakening of zinc powder Cathodic protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

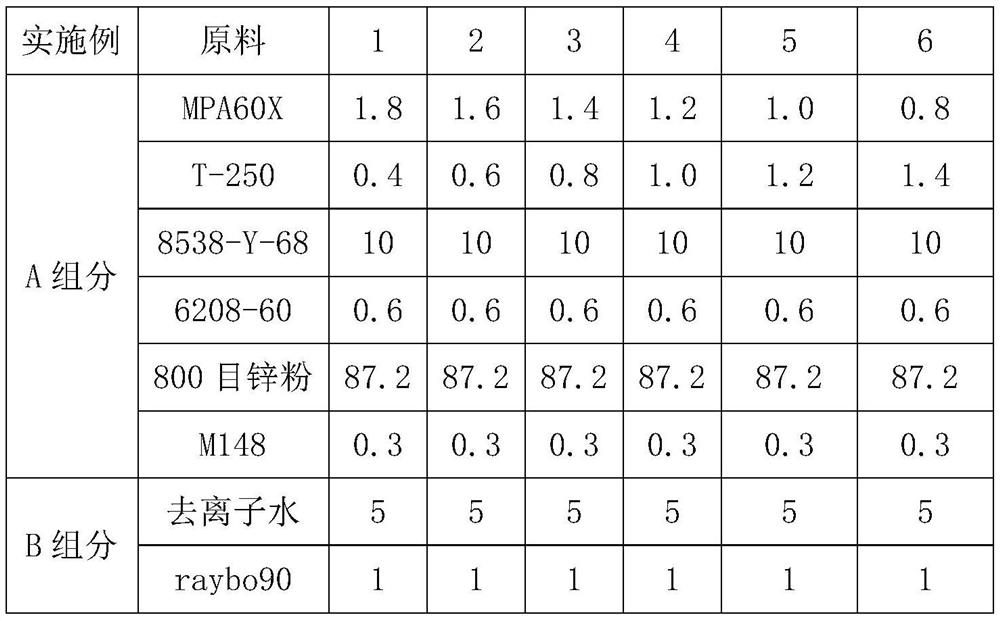

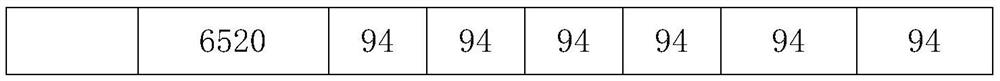

[0055] Embodiment 1-6 concrete proportioning (weight part) is as shown in table 1 below:

[0056] Table 1

[0057]

[0058]

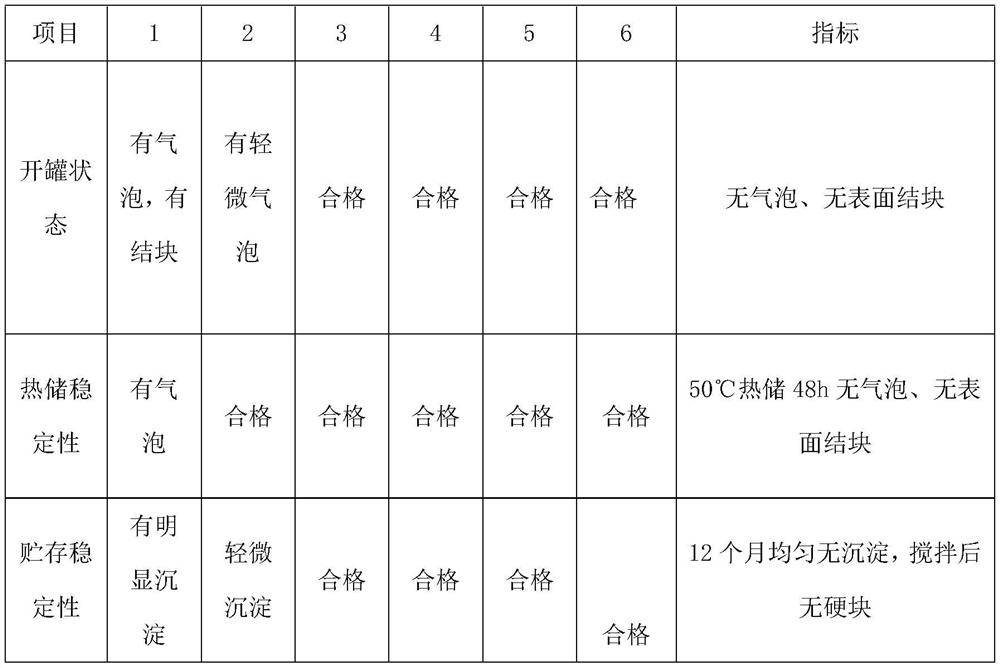

[0059] Stability test:

[0060] 1. According to the ratio of component A in Table 1, add MPA60X rheology agent, T-250 fatty acid amide anti-sedimentation agent and dispersant to 6 container tanks respectively (marked according to the components of Examples 1-6 ), stirring and dispersing at 500-1000 rpm.

[0061] 2. According to the ratio of component A in Table 1, add 800 mesh zinc powder and defoamer to the above 6 containers to obtain component A in the container.

[0062] 3. Fully mix the dissolved epoxy emulsion 6520 and raybo90 anti-flash rust agent according to the ratio of component B in Table 1, and add deionized water to obtain component B.

[0063] 4. Add component B in step 3 to component A in 6 tanks while fully dispersing and stirring, wherein the weight ratio of component A and component B is 4:1.

[0064] 5. After fully stirring a...

Embodiment 7-12

[0081] Spray test 2:

[0082] Table 4

[0083]

[0084] 1. According to the ratio of A component in Table 4, add MPA60X rheological agent, PEDOT, T-250 fatty acid amide anti-settling agent and dispersant to 6 container tanks respectively (according to the components of Examples 7-12 mark), stir and disperse at 500-1000 rpm.

[0085] 2. According to the ratio of component A in Table 1, add 800 mesh zinc powder, 8538-Y-68 amine epoxy curing agent, and defoamer to the above-mentioned 6 containers to obtain component A in the container .

[0086] 3. Fully mix the dissolved epoxy emulsion 6520 and raybo90 anti-flash rust agent according to the ratio of component B in Table 1, and add deionized water to obtain component B.

[0087] 4. Add component B in step 3 to component A in 6 tanks while fully dispersing and stirring, wherein the weight ratio of component A and component B is 4:1, and stir thoroughly for 2-4min until fully blended.

[0088] 5. Add 15-20% water by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com