Diaphragm for nickel-cadmium battery, preparation method thereof and battery

A nickel-cadmium battery and diaphragm technology, which is applied in the direction of nickel storage battery, alkaline storage battery, battery pack parts, etc., can solve the cycle performance degradation? Low-level problems, to achieve the effect of improving charging efficiency, increasing the rate of oxygen absorption by the negative electrode, and preventing growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention discloses a method for preparing a diaphragm for a nickel-cadmium battery. The base material is dipped in an aqueous solution of manganese salt, taken out after dipping, and dried. The soaking time is not particularly limited, as long as the substrate can be completely wetted, the soaking time in the embodiment of the present invention is preferably 30-50 min. The drying method is a general drying method known to those skilled in the art, such as natural drying or heating drying, etc., and the temperature of heating drying generally does not exceed 180°C.

[0017] The concentration of the manganese salt in the aqueous solution containing the manganese salt can be any concentration, preferably the weight percentage of the manganese salt in the aqueous solution containing the manganese salt is 0.6%-12%.

[0018] A secondary nickel-cadmium battery, the battery includes a pole core and an alkaline electrolyte, the pole core and the alkaline electrolyte are sea...

Embodiment 1

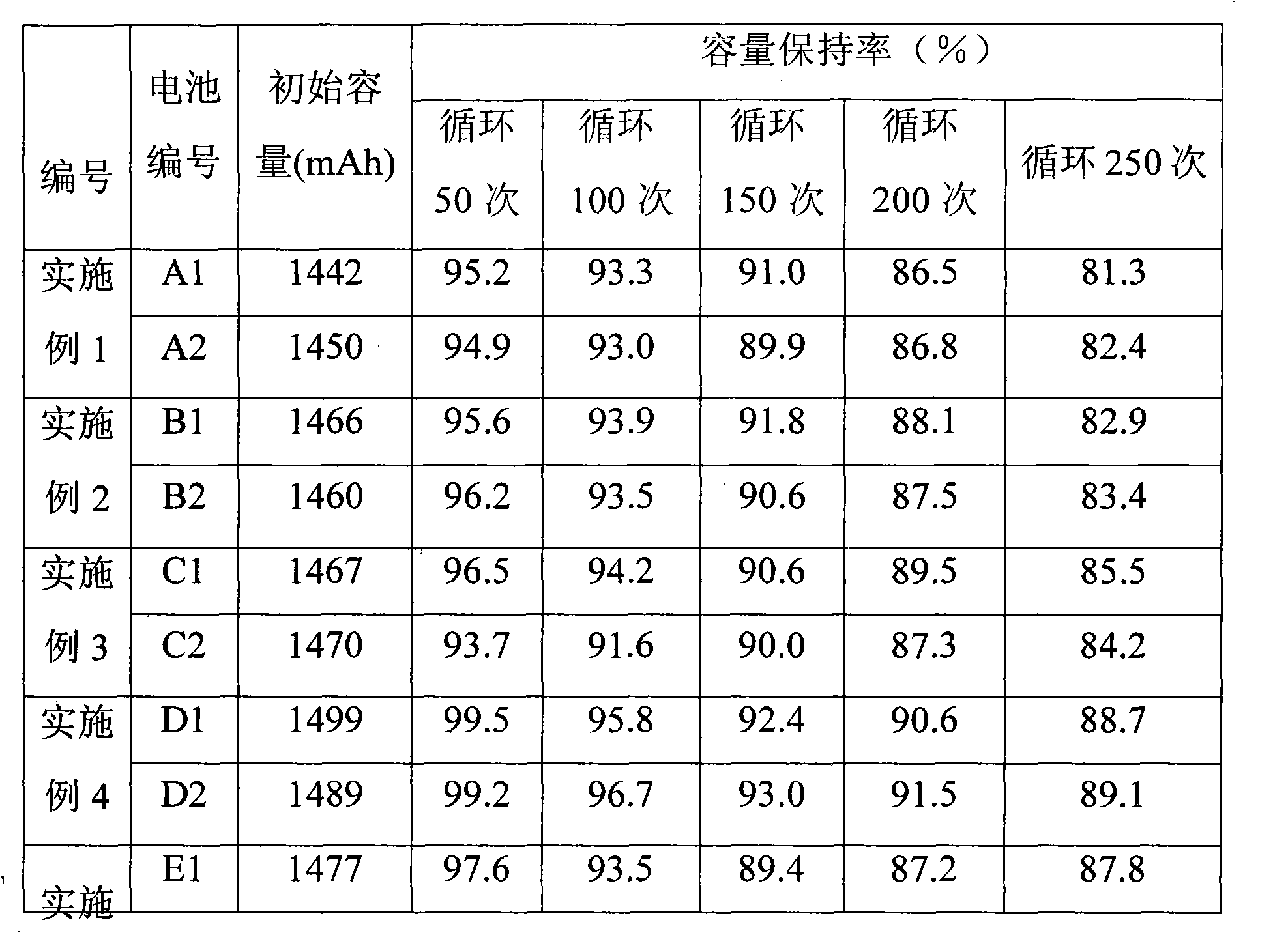

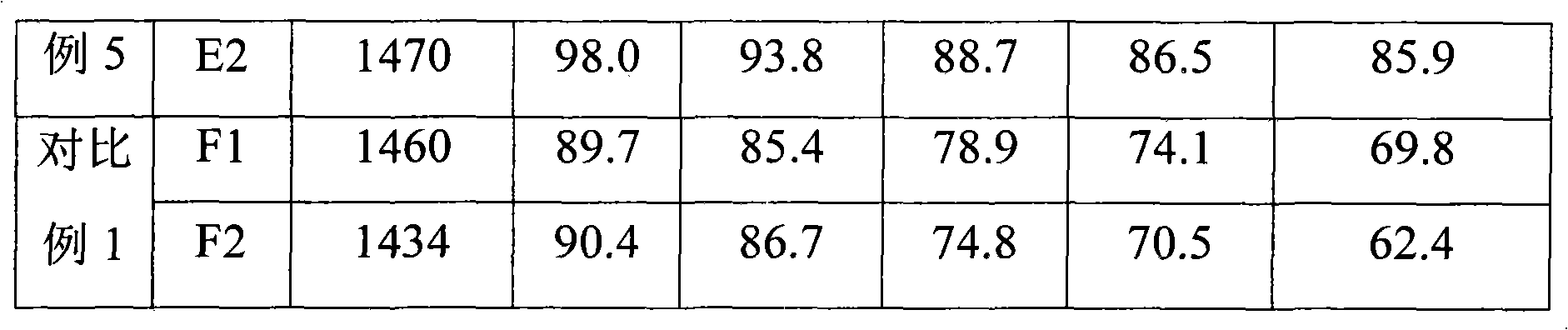

[0025] This embodiment is used to illustrate the secondary nickel-cadmium battery provided by the present invention

[0026] (1) Preparation of diaphragm

[0027] Set the areal density to 60g / m 2 Nylon fiber paper with a liquid absorption rate of 300% is continuously passed through a certain 0.6wt% manganese sulfate solution, and the immersion time of the diaphragm in the solution is guaranteed to be 30 minutes. After immersion, the nylon fiber paper is taken out and dried at 45°C. Cutting and cutting to make the finished separator paper, the size of the separator paper is 445mm×34.5mm×0.15mm. The measured content of manganese salt in the diaphragm is 5g / m 2 . The method for measuring the manganese salt content in the diaphragm after impregnation is: weigh the weight of the diaphragm before impregnation, and record it as X g / m 2 , the weight of the membrane after dipping and drying, denoted as Y g / m 2 , then the content of manganese salt in the diaphragm is (Y-X)g / m 2 . ...

Embodiment 2

[0035] This embodiment is used to illustrate the secondary nickel-cadmium battery provided by the present invention

[0036](1) Preparation of diaphragm

[0037] Set the areal density to 60g / m 2 Diaphragm nylon fiber paper with a liquid absorption rate of 300% is continuously passed through a certain 4.2%wt manganese sulfate solution, and the soaking time is 50 minutes. After dipping, the nylon fiber paper is taken out, dried at 45°C, and cut and cut. Finished separator paper, the size of separator paper is 445mm×34.5mm×0.15mm. The measured content of manganese salt in the diaphragm is 15g / m 2 .

[0038] (2) Preparation of negative electrode

[0039] With 75 kilograms of negative electrode active material cadmium oxide, 5 kilograms of sponge cadmium (Hebei Dacheng Company) and 10 kilograms concentration are the aqueous solution of 3% by weight of hydroxypropyl methylcellulose and 4 kilograms of water, fully stir, then add 1.2 kilograms of solid The polytetrafluoroethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com