Cadmium negative pole, preparation method thereof and secondary nickel-cadmium battery containing same

A nickel-cadmium battery and negative electrode technology, which is applied to nickel batteries, battery electrodes, alkaline batteries, etc., can solve the problems of easy enhancement of electrode polarization, poor battery discharge performance, hindering the movement of electrons and ions, etc., so as to improve the initial capacity. , The consistency of the battery is improved, and the effect of small current charging is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

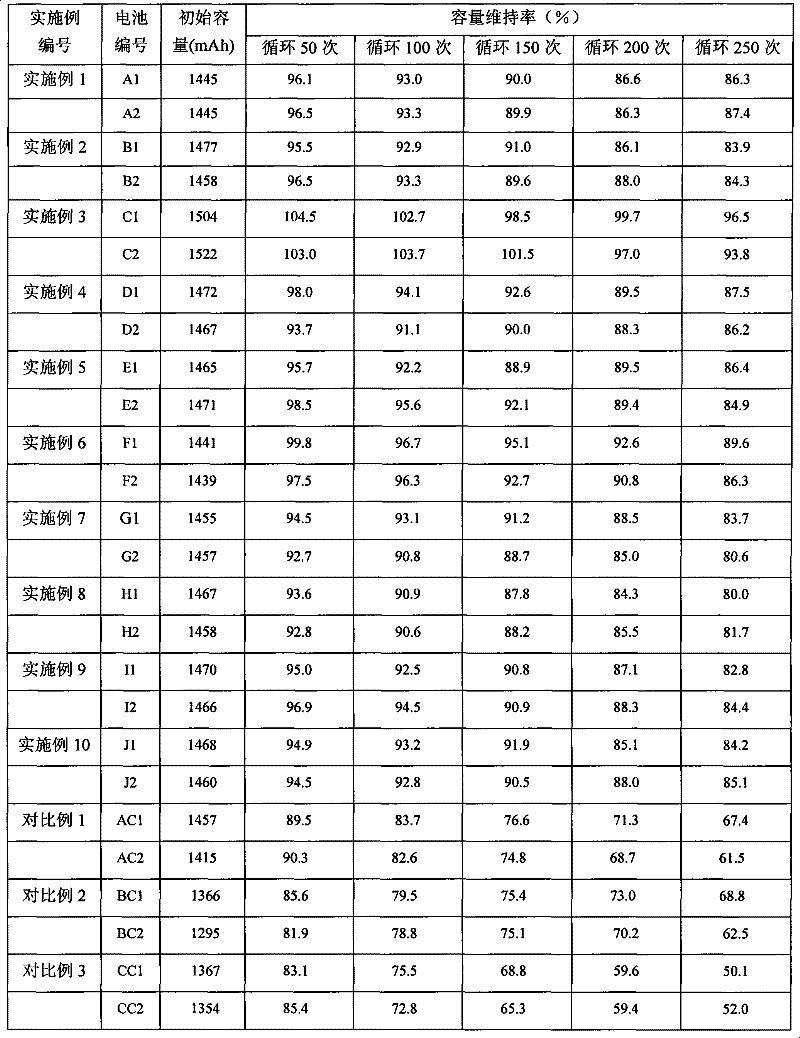

Examples

preparation example Construction

[0024] In the preparation method of the cadmium negative electrode according to the present invention, the raw materials used are as defined above for the cadmium negative electrode in the present invention, and will not be described in detail here.

[0025] The amounts of solvent, negative electrode active material and negative electrode binder in the slurry are known to those skilled in the art. Generally speaking, based on the weight of the negative active material, the content of the solvent may be 15-60% by weight, preferably 15-50% by weight. The solvent may be selected from N-methylpyrrolidone (NMP), dimethylformamide (DMF), diethylformamide (DEF), dimethylsulfoxide (DMSO), tetrahydrofuran (THF) and water and alcohol One or several types; the amount of the solvent can make the paste have viscosity and fluidity, and can be coated on the conductive substrate. Wherein, the methods and conditions of drying and calendering are well known to those skilled in the art.

[002...

Embodiment 1

[0036] This embodiment is used to illustrate the secondary nickel-cadmium battery provided by the present invention

[0037] (1) Preparation of negative electrode

[0038] With 75 kilograms of negative electrode active material cadmium oxide, 5 kilograms of sponge cadmium (Hebei Dacheng Company) and 10 kilograms concentration are the aqueous solution of 3% by weight of hydroxypropyl methylcellulose and 4 kilograms of water, fully stir, then add 1.2 kilograms of solid The polytetrafluoroethylene suspension with a content of 60% by weight, 1.6 kg of an aqueous solution of styrene-butadiene rubber with a concentration of 60% by weight and 1.8 kg of a PVA solution with a concentration of 4% by weight were mixed and stirred evenly, and finally 0.5 kg of conductive metal oxide was added LiMn 2 o 4 , mixed and stirred to form a uniform negative electrode slurry.

[0039] The slurry is evenly coated on a nickel-plated perforated steel strip with a width of 220 mm and a thickness of...

Embodiment 2

[0045] This embodiment is used to illustrate the secondary nickel-cadmium battery provided by the present invention

[0046] (1) Preparation of negative electrode

[0047] With 75 kilograms of negative electrode active material cadmium oxide, 5 kilograms of sponge cadmium (Hebei Dacheng Company) and 0.5 kilogram of graphite, 16 kilograms of concentration are the aqueous solution and 3 kilograms of water of the hydroxypropyl methylcellulose of 3 weight %, fully stir, then Add 1 kg of polytetrafluoroethylene suspension with a solid content of 60% by weight, 1.5 kg of styrene-butadiene rubber aqueous solution with a concentration of 60% by weight, and 1 kg of PVA with a concentration of 10% by weight, mix and stir evenly, and finally add 1.8 kg of conductive metal oxide LiMn 2 o 4 , mixed and stirred to form a uniform negative electrode slurry.

[0048] The slurry is evenly coated on a nickel-plated perforated steel strip with a width of 220 mm and a thickness of 80 microns, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com