Coloring treatment method of metal zipper component and metal zipper

A metal zipper and processing method technology, applied in the field of zipper, can solve the problems of few types of zipper processing and limited material selection, and achieve the effects of low cost, high efficiency and simple processing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

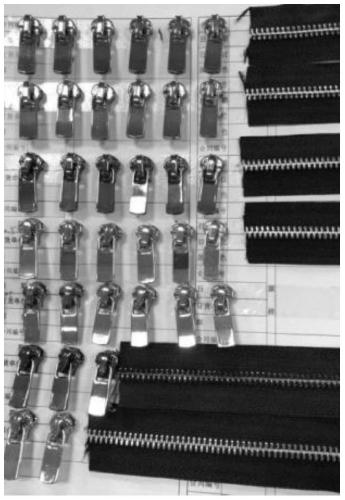

Image

Examples

Embodiment 1

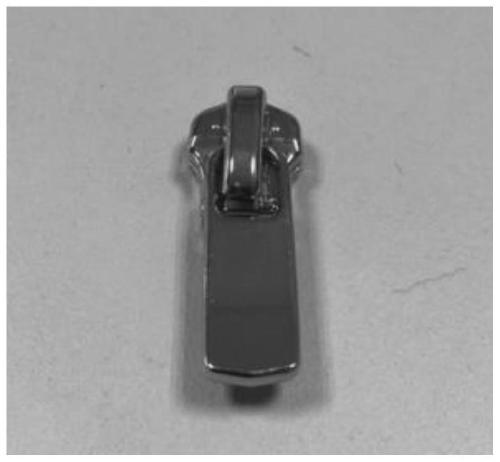

[0056] 1. Put the 50g slider (such as figure 2 As shown, the copper-zinc alloy material, the model is No. 5) is polished in a common way in the industry, and then washed 3 times with clean water before use;

[0057] 2. Use 3% alkaline degreaser to degrease the polished slider. The degreasing temperature is 65°C-75°C. After 3-5 minutes of degreasing, immediately wash it with water for 3 times, and set it aside;

[0058] 3. Activate the degreased slider with 3% activation solution, wash it with water for 3 times after 30 seconds, and set it aside;

[0059] 4. Electroplate the activated slider into a nickel color, and then wash it with water for 4 times before use; the thickness of the coating is 0.08-0.1mm;

[0060] 5. Dry the electroplated slider at 120°C for 5 minutes. After cooling down, perform the industry-wide oil sealing (transparent frame) treatment (use the transparent frame oil A agent + B agent mentioned above), and then Drying at 120°C for 10 minutes; the thicknes...

Embodiment 2

[0075] 1. Polish the 50g slider (copper-zinc alloy material, model No. 5) with the general method in the industry, and then wash it with clean water for 3 times before use;

[0076] 2. Use 3% alkaline degreaser to degrease the polished slider. The degreasing temperature is 65°C-75°C. After 3-5 minutes of degreasing, immediately wash it with water for 3 times, and set it aside;

[0077] 3. Activate the degreased slider with 3% activation solution, wash it with water for 3 times after 30 seconds, and set it aside;

[0078] 4. Chemically tin-plate the activated slider, and then wash it with water for 4 times before use; the thickness of the coating is 0.08-0.1mm;

[0079] 5. Dry the electroless-plated slider at 120°C for 5 minutes, carry out the industry's general oil sealing (transparent frame) treatment (same as Example 1), and then dry it at 120°C for 10 minutes;

[0080] 6. Put the slider of Guohaola rack into the coloring solution for coloring. The coloring formula is as fo...

Embodiment 3

[0092] 1. Polish the 50g slider (copper-zinc alloy material, model No. 5) with the general method in the industry, and then wash it with clean water for 3 times before use;

[0093] 2. Use 3% alkaline degreaser to degrease the polished slider. The degreasing temperature is 65°C-75°C. After 3-5 minutes of degreasing, immediately wash it with water for 3 times, and set it aside;

[0094] 3. Activate the degreased slider with 3% activation solution, wash it with water for 3 times after 30 seconds, and set it aside;

[0095] 4. Electroplate the activated slider into a nickel color, and then wash it with water for 4 times before use; the thickness of the coating is 0.08-0.1mm;

[0096] 5. Dry the electroplated slider at 120°C for 5 minutes, carry out the industry general oil sealing (transparent frame) treatment (same as Example 1), and then dry at 120°C for 10 minutes;

[0097] 6. Put the slider of Guohaola rack into the coloring solution for coloring. The coloring formula is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com