Flame retardant curing solution and technology for manufacturing halogen free nanometer high temperature resistant cotton yarn filling rope by utilizing same

A manufacturing process and high-temperature-resistant technology, which is applied in cable/conductor manufacturing, textile and paper making, conductors, etc., can solve the problems of high price, large specific gravity, and no flame retardancy, and achieve the effect of low price and light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

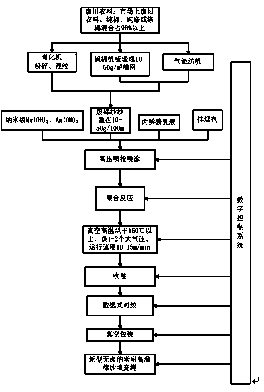

[0027] The present invention carries out according to the following processing steps:

[0028] 1) Raw materials: Waste and old clothing materials on the market (pure cotton, pure polyester or polyester-cotton blends account for more than 98%), which are crushed and twisted into shredded cotton by bale opening machines, opening machines or greening machines;

[0029] 2) The broken cotton is combed into 10g / m by carding machine 2 Cotton net is spun into waste cotton yarn through air spinning machine, and its yarn weight is 10g / 100m;

[0030] 3) The mass percentage is: nano-scale Mg (OH) 2 , AL (OH) 3 A mixed solution of 75%, 24.5% acrylic acid emulsion, and 0.5% water-soluble neutral smoke suppressant zinc aluminate is evenly sprayed on the surface of the above-mentioned waste cotton yarn by a high-pressure spray gun, and the spray volume is 90g / m 2 ;

[0031] 4) Polymerization reaction: At a high temperature of 150°C, the above mixed solution and waste cotton yarn ar...

Embodiment 2

[0038] The present invention carries out according to the following processing steps:

[0039] 1) Raw materials: Waste and old clothing materials on the market (pure cotton, pure polyester or polyester-cotton blends account for more than 98%), which are crushed and twisted into shredded cotton by bale opening machines, opening machines or greening machines;

[0040] 2) The broken cotton is combed into 15g / m by carding machine 2 The cotton net is then spun into waste cotton yarn through an air spinning machine, and the yarn weight is 50g / 100m;

[0041] 3) The mass percentage is: nano-scale Mg (OH) 2 , AL (OH) 3 A mixed solution of 90%, 9% acrylic acid emulsion, and 1% water-soluble neutral smoke suppressant zinc aluminate is evenly sprayed on the surface of the above-mentioned waste cotton yarn by a high-pressure spray gun, and the spray volume is 120g / m 2 ;

[0042] 4) Polymerization reaction: At a high temperature of 180°C, the above mixed solution and waste cotton ...

Embodiment 3

[0049] The present invention carries out according to the following processing steps:

[0050] 1) Raw materials: Waste and old clothing materials on the market (pure cotton, pure polyester or polyester-cotton blends account for more than 98%), which are crushed and twisted into shredded cotton by bale opening machines, opening machines or greening machines;

[0051] 2) The broken cotton is combed into 12g / m by carding machine 2 The cotton net is spun into waste cotton yarn through air spinning machine, and the yarn weight is 30g / 100m;

[0052] 3) The mass percentage is: nano-scale Mg (OH) 2 , AL (OH) 3 A mixed solution of 80%, 19.2% acrylic acid emulsion, and 0.8% water-soluble neutral smoke suppressant zinc aluminate is evenly sprayed on the surface of the above-mentioned waste cotton yarn by a high-pressure spray gun, and the spray volume is 100g / m 2 ;

[0053] 4) Polymerization reaction: At a high temperature of 160°C, the above mixed solution and waste cotton ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com