Novel environment-friendly nontoxic epoxy floor coating and preparation method thereof

An epoxy floor and environmental protection technology, applied in epoxy resin coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as low VOC emissions, low odor, and unsatisfactory resistance to strong acids and alkalis and high corrosion performance , achieve high corrosion resistance, high decoration, and meet the effect of VOC emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

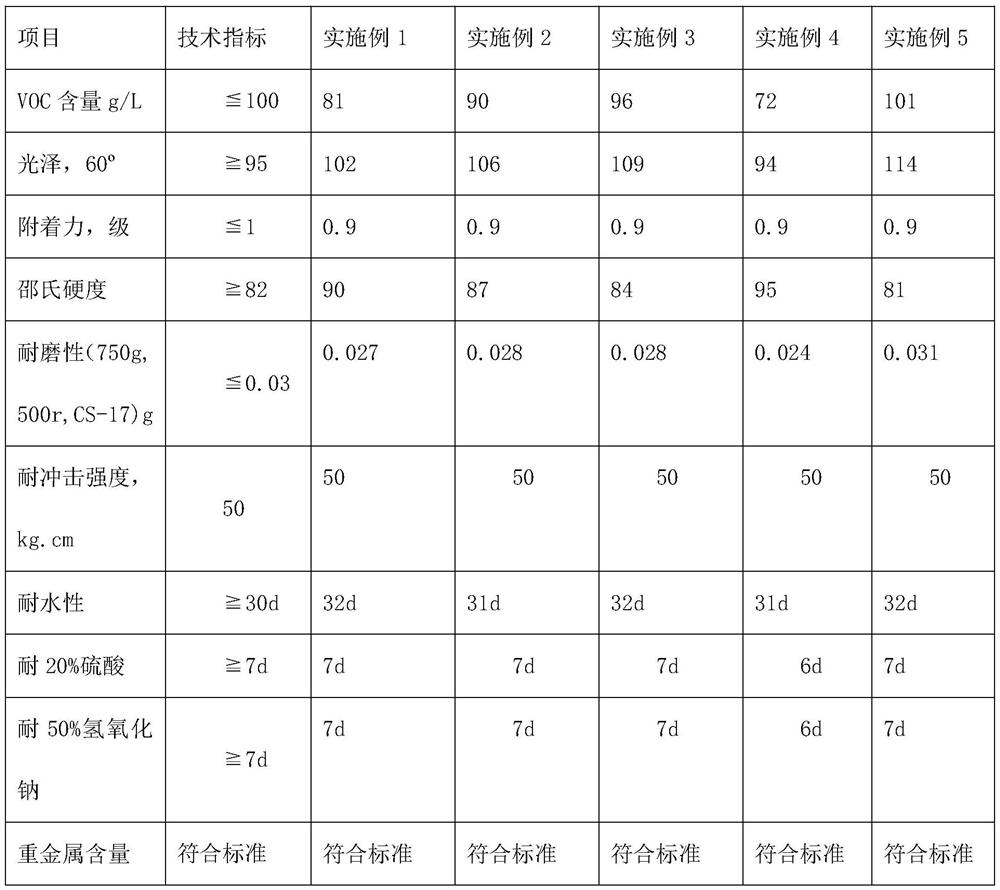

Examples

Embodiment 1

[0024] A kind of above-mentioned high weather resistance self-cleaning anti-icing coating comprises two kinds of components of A and B, and its preparation method comprises the steps:

[0025] Weigh the following materials in parts by mass, including 40 parts of epoxy resin E-44, 10 parts of glycidyl neodecanoate, 0.5 parts of leveling agent, 0.5 parts of defoamer, 5 parts of organic pigments, 50 parts of quartz stone, 0.5 parts of wetting agent;

[0026] Pour the material in the previous step into the mixing hopper, mix, use a mixer to stir in the mixing process, and control the stirring speed at 400-500 revolutions per minute;

[0027] Pour the material mixed in the previous step onto the paint disperser, and add 1 part of low molecular weight polyethylene wax, and the paint disperser disperses the material at a high speed to disperse evenly;

[0028] The uniformly dispersed material is put into a three-roller machine to grind the material. During the grinding process, the ...

Embodiment 2

[0033] A kind of above-mentioned high weather resistance self-cleaning anti-icing coating comprises two kinds of components of A and B, and its preparation method comprises the steps:

[0034] Weigh the following materials in parts by mass, including 50 parts of epoxy resin E-44, 8 parts of glycidyl neodecanoate, 0.5 parts of leveling agent, 0.5 parts of defoamer, 10 parts of organic pigments, 45 parts of quartz stone, 0.5 parts of wetting agent;

[0035] Pour the material in the previous step into the mixing hopper, mix, use a mixer to stir in the mixing process, and control the stirring speed at 400-500 revolutions per minute;

[0036] Pour the material mixed in the previous step onto the paint disperser, and add 1 part of low molecular weight polyethylene wax, and the paint disperser disperses the material at a high speed to disperse evenly;

[0037] The uniformly dispersed material is put into a three-roller machine to grind the material. During the grinding process, the ...

Embodiment 3

[0042] A kind of above-mentioned high weather resistance self-cleaning anti-icing coating comprises two kinds of components of A and B, and its preparation method comprises the steps:

[0043] Weigh the following materials in parts by mass, including 60 parts of epoxy resin E-44, 5 parts of glycidyl neodecanoate, 0.5 parts of leveling agent, 0.5 parts of defoamer, 5 parts of organic pigments, 40 parts of quartz stone, 0.5 parts of wetting agent;

[0044] Pour the material in the previous step into the mixing hopper, mix, use a mixer to stir in the mixing process, and control the stirring speed at 400-500 revolutions per minute;

[0045] Pour the material mixed in the previous step onto the paint disperser, and add 1 part of low molecular weight polyethylene wax, and the paint disperser disperses the material at a high speed to disperse evenly;

[0046] The uniformly dispersed material is put into a three-roller machine to grind the material. During the grinding process, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com