A kind of halogen-free low-smoke flame-retardant rubber for wire and cable and preparation method thereof

A wire and cable, low-smoke flame retardant technology, applied in the field of halogen-free low-smoke flame retardant rubber and its preparation, can solve the problems of high smoke density, difficult escape, human suffocation, etc., achieve good mechanical properties, good flame retardant effect, Promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

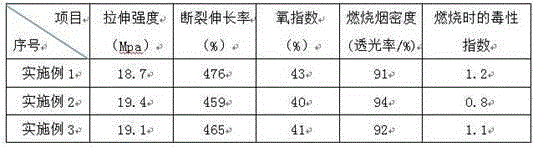

Examples

Embodiment 1

[0012] A halogen-free low-smoke flame-retardant rubber for wire and cable, made of the following raw materials (kg): EPDM rubber 100, methyl vinyl silicone rubber 45, nylon 101030, EPDM rubber grafted Toric anhydride 15, tert-butylcatechol 2, terpene resin 5, rosin glyceride 4, tall oil 10, zinc oxide 3, stearic acid 1, anti-aging agent 4010NA1.5, anti-aging agent 10761, accelerator DTDM2, accelerator Agent DZ1, magnesium hydroxide 16, mica powder 10, resorcinol bis(diphenyl phosphate) 12, thiodipropionic acid 2.5, polytrimethylene adipate 5, dicumyl peroxide 2, three Allyl isocyanurate 1.5, modified filler 18;

[0013] The preparation method of the modified filler is as follows: (1) Weigh sillimanite, oil shale, and attapulgite at a weight ratio of 4:3:2, mix them evenly, grind them, and sieve them, and then pure NH at 650°C 3 Calcined under the atmosphere for 1 h, then pure H at 360 °C 2 Calcined under atmosphere for 2 hours, cooled naturally to room temperature; (2) Take ...

Embodiment 2

[0016] A halogen-free low-smoke flame-retardant rubber for wire and cable, made of the following raw materials (kg): EPDM rubber 120, methyl vinyl silicone rubber 55, nylon 101040, EPDM rubber grafted Toric anhydride 20, tert-butylcatechol 3, terpene resin 8, rosin glyceride 5, tall oil 12, zinc oxide 4, stearic acid 1.5, antioxidant 4010NA2, antioxidant 10761.5, accelerator DTDM2.5, accelerator Agent DZ1.5, magnesium hydroxide 18, mica powder 12, resorcinol bis(diphenyl phosphate) 16, thiodipropionic acid 3.5, polytrimethylene adipate 8, dicumyl peroxide 3 , triallyl isocyanurate 2, modified filler 22;

[0017] The preparation method of the modified filler is as follows: (1) Weigh sillimanite, oil shale, and attapulgite at a weight ratio of 6:4:2.5, mix them evenly, crush them, and sieve them, then pure NH at 700°C 3 Calcined under the atmosphere for 1h, then pure H at 380°C 2 Calcined under atmosphere for 1.5h, cooled naturally to room temperature; (2) Take 22% nano-silica...

Embodiment 3

[0020] A halogen-free low-smoke flame-retardant rubber for wire and cable, made of the following raw materials in parts by weight: EPDM rubber 150, methyl vinyl silicone rubber 65, nylon 101050, EPDM rubber grafted with maleic anhydride 25. Tertiary butyl catechol 4, terpene resin 10, rosin glyceride 6, tall oil 15, zinc oxide 5, stearic acid 2, antioxidant 4010NA2.5, antioxidant 10762, accelerator DTDM3, accelerator DZ2 , magnesium hydroxide 22, mica powder 15, resorcinol bis(diphenyl phosphate) 18, thiodipropionic acid 4.5, polytrimethylene adipate 10, dicumyl peroxide 4, triallyl Base isocyanurate 2.5, modified filler 24;

[0021] The preparation method of the modified filler is as follows: (1) Weigh sillimanite, oil shale, and attapulgite at a weight ratio of 8:5:3, mix them evenly, grind them, and sieve them, and then pure NH at 750°C 3 Calcined under the atmosphere for 0.5h, then pure H at 420°C 2 Calcined under atmosphere for 1h, cooled naturally to room temperature; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com