Fuel cell with humidity control

A fuel cell and battery technology, applied in fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of complicated humidification device, increase of water vapor, and interruption of normal operation of batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For the sake of clarity, the same elements in different drawings have the same reference numerals, moreover, as is done in the representation of integrated components, the different drawings are not to scale.

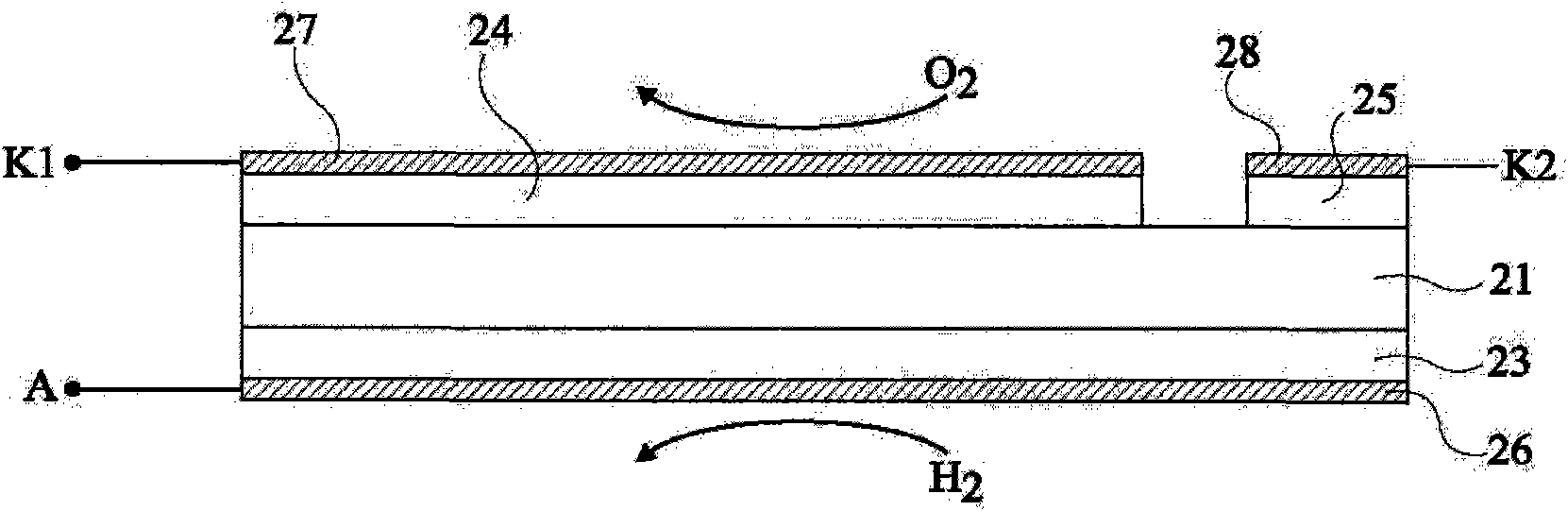

[0026] image 3 Highly schematically shown (similar to figure 1 ) A general structure of a fuel cell according to one embodiment of the present invention. The fuel cell is divided into a main cell and an auxiliary cell sharing the same electrolyte 21 . The lower surface side has a catalyst layer 23 and a conductive layer 26 . Arranged on the upper surface side are a first main catalyst layer 24 and a second subsidiary catalyst layer 25, which are separated and plated with metal plating layers 27 and 28, respectively. Thus, the battery comprises a single anode A and two cathodes K1 and K2. as combined below Figure 6 As explained, the cathode K2 is located, for example, on the periphery with respect to the cathode K1. Since the electrolyte is water permeable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com