Electrical connector for flexible printed circuit board

A technology of flexible circuit boards and electrical connectors, applied in the direction of circuits, connections, fixed connections, etc., can solve the problems of compact connectors, increase the physical size of connectors, etc., and achieve the effect of simple and stable connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

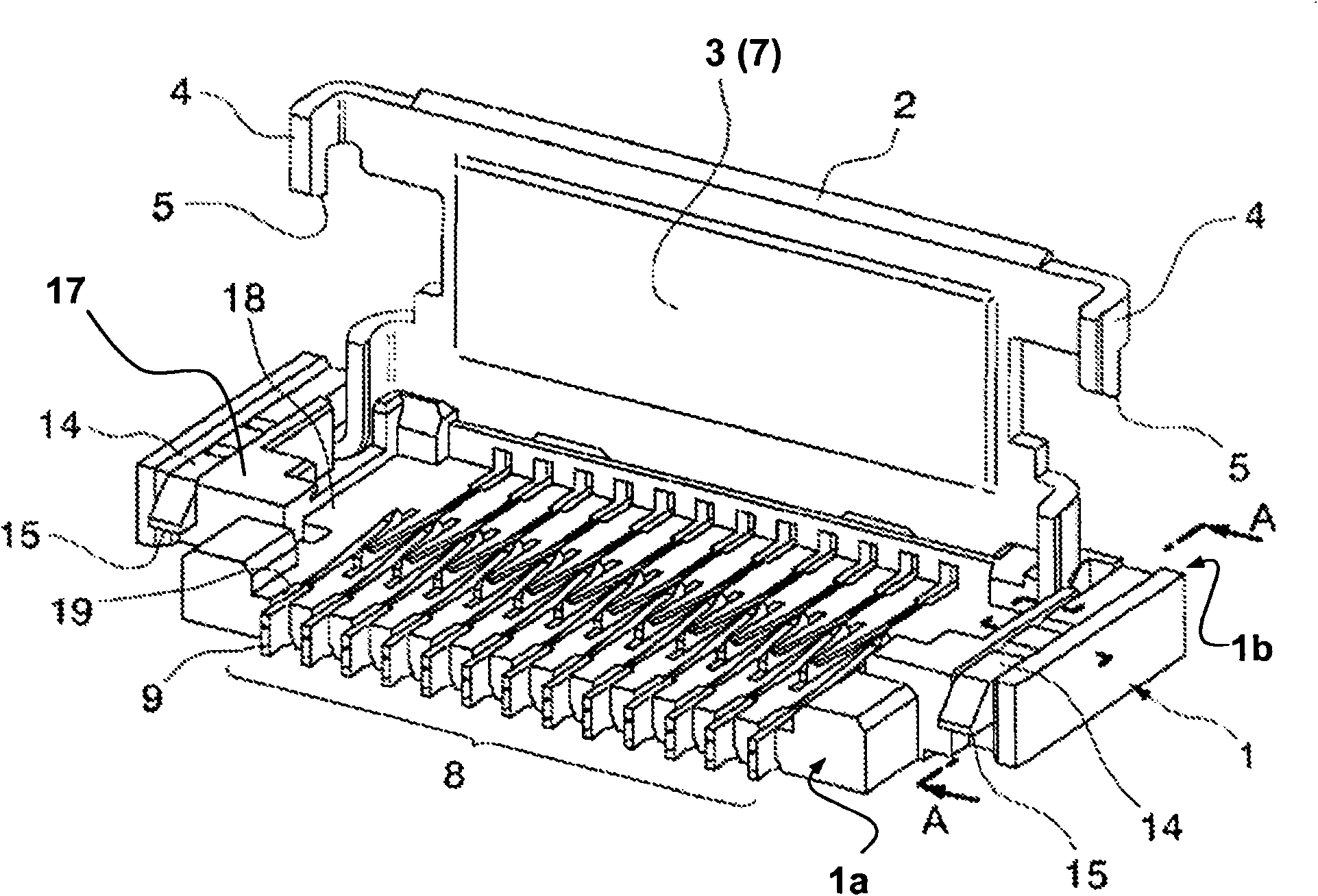

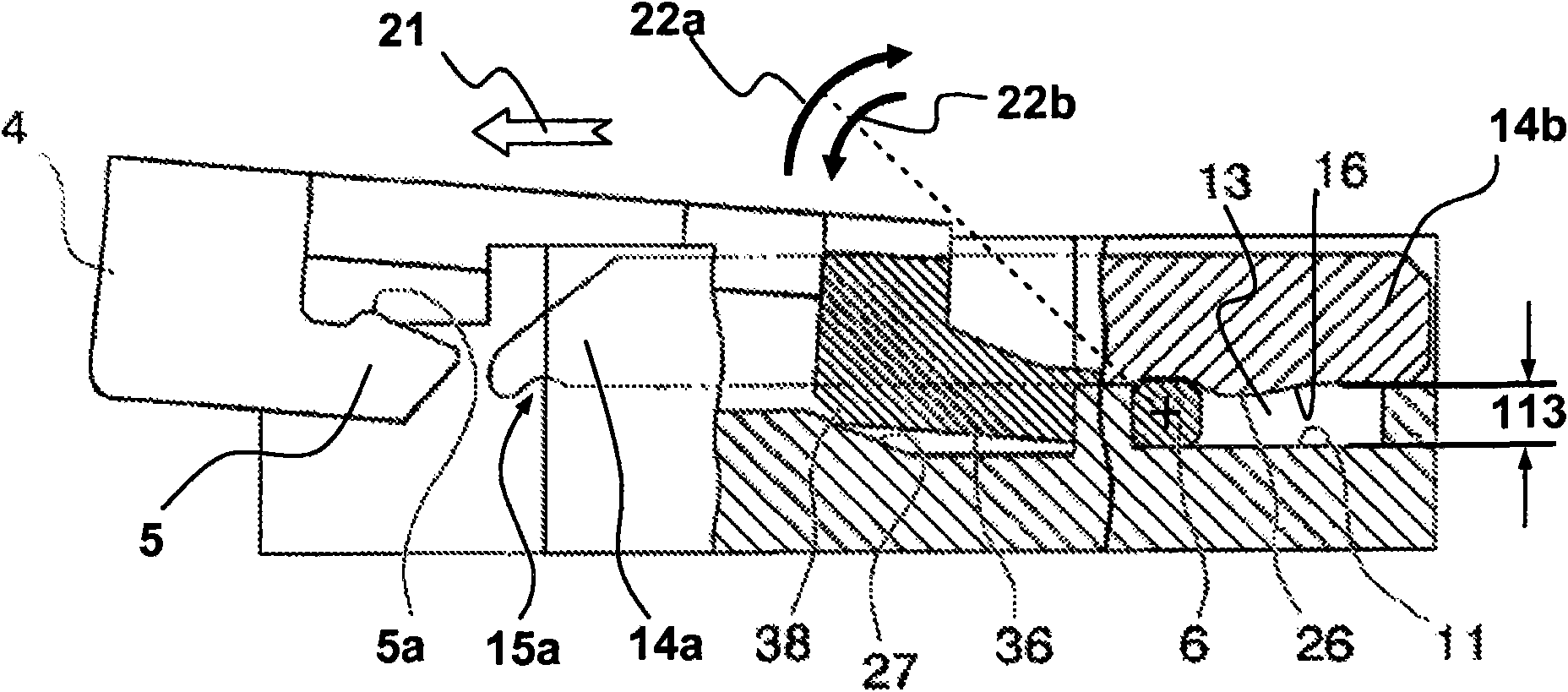

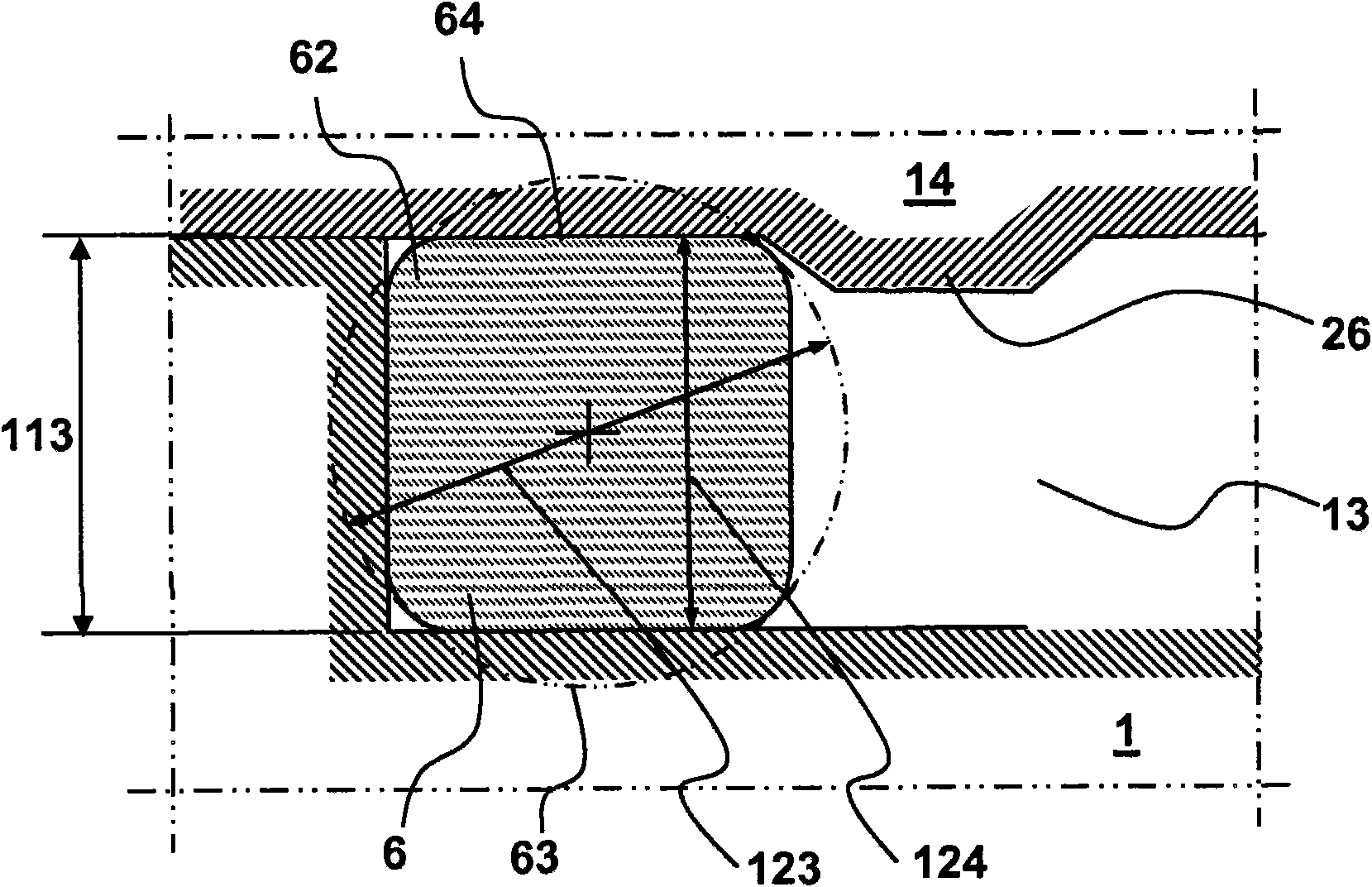

[0023] like figure 1 As shown, an electrical connector according to one embodiment of the present invention has: a main body 1 made of molded resin; an actuator 2 that can be attached to or removed from the main body 1; Lock 14. The main body 1 has a front end 1a and a rear end 1b.

[0024] The main body 1 has a support surface 18 for receiving the distal end of the flexible circuit board 30 . A terminal groove 19 is formed on the supporting surface 18, into which a plurality of terminals 9 constituting the electrode 8 are inserted. The terminal 9 protrudes slightly from the terminal groove 19 so as to contact the flexible circuit board 30 .

[0025] The body 1 has a side wall 17 partially surrounding a support surface 18 . A first slit 12 a parallel to the support surface 18 is formed at a corner portion of the side wall 17 into which a corner portion of the distal end of the flexible circuit board 30 can be inserted.

[0026] in as Figure 4 In an alternative embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com