Chain for vehicle

A technology for chains and vehicles, applied in the direction of chain rings, transmission chains, etc., can solve the problems of loose structure, inability to select odd and even numbers, affecting the strength of chain pieces, etc., and achieve the effect of prolonging the service life, improving the overall strength and improving the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

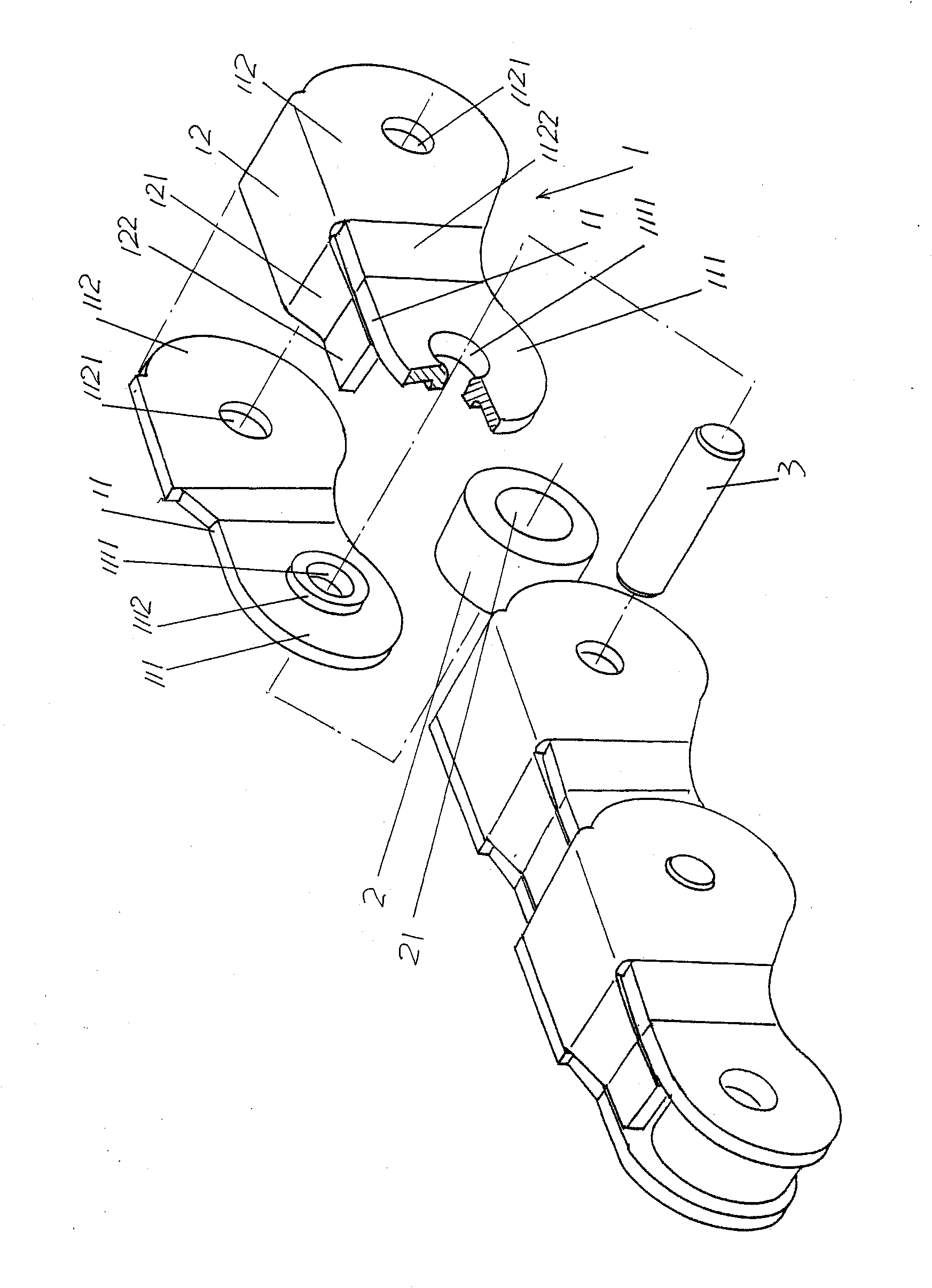

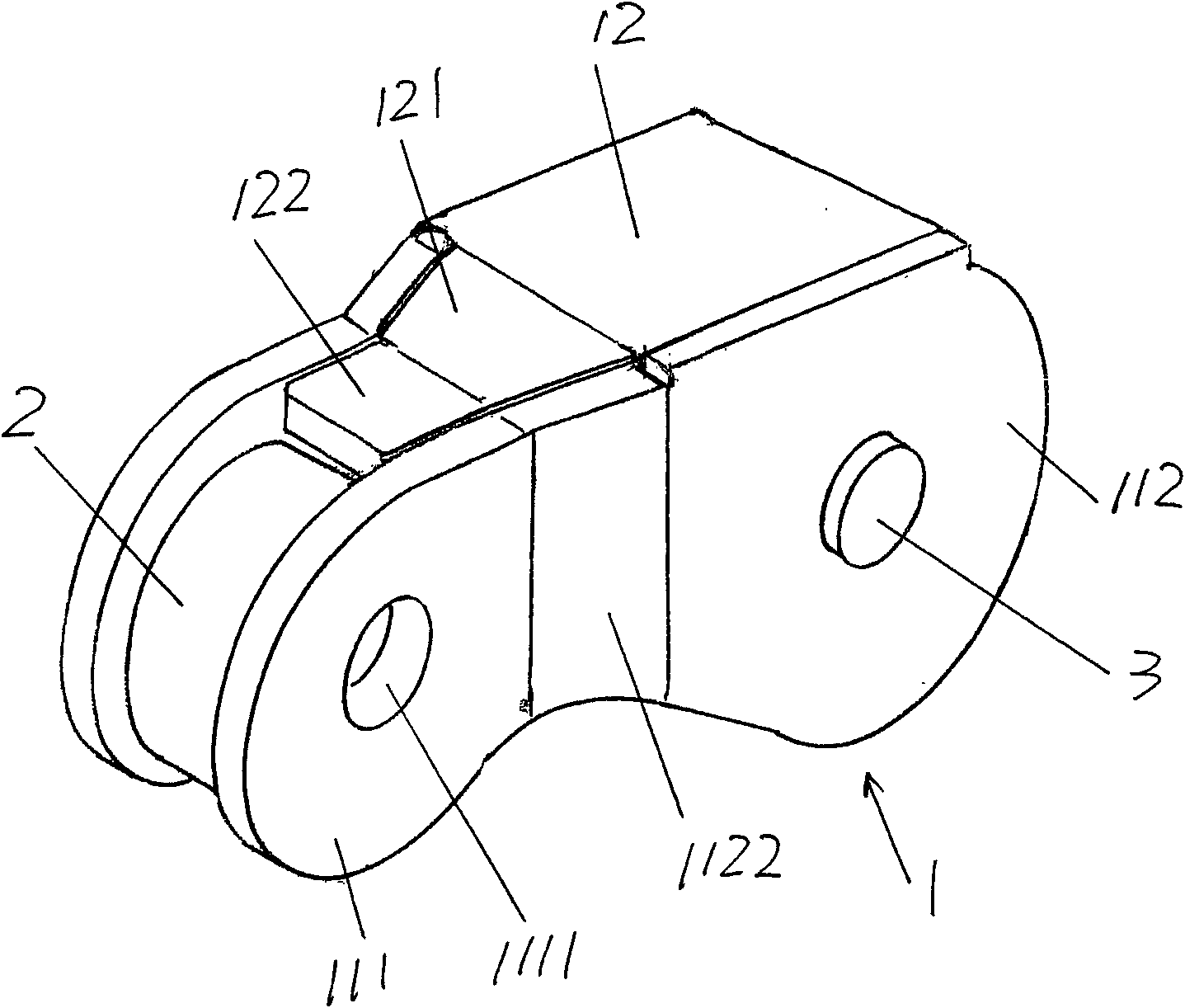

[0020] Please see figure 1 with figure 2 , in this example, although in figure 1 only shows the chain link body 1 of three units, but it is obviously not limited by the number shown in the figure, as long as it is based on the structural form shown in the figure and in accordance with the applicant's detailed description below, the chain link body of the required number can be made 1, and the rollers 2 and hinge shafts 3 matching the number of the chain link body 1 are repeatedly connected to obtain a chain of required length. The materials of the chain link body 1, the roller 2 and the hinge shaft 3 mentioned above are all metal.

[0021] It is composed of a pair of chain pieces 11 parallel to each other and a tongue-shaped sealing plate 12 for closing one of the upper and lower openings of the chain piece 11 formed between the pair of chain pieces 11 in the length direction. is the chain link body 1, with current consisting of figure 1 The position state shown is an exa...

Embodiment 2

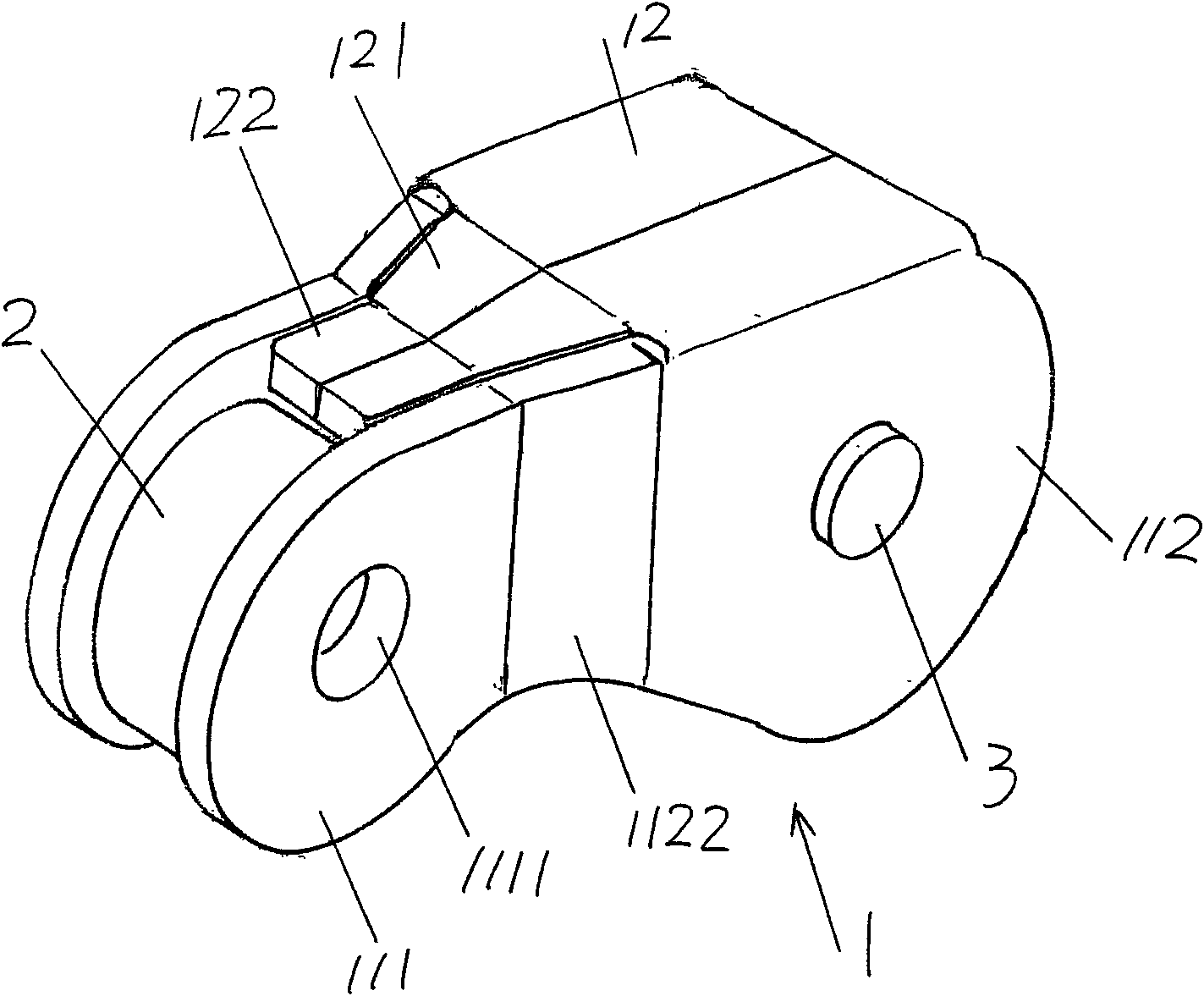

[0025] please see image 3 , the number of tongue-shaped sealing plates 12 is a pair, and one of the tongue-shaped sealing plates 12 is formed on one of the connecting large mortar plates 112 in a pair of connecting large mortar plates 112, that is, it is formed by bending on the connecting large mortar plates 112, And another tongue-shaped sealing plate 12 is then formed on another connecting large mortar plate 112 in a pair of connecting large mortar plates 112, promptly forms at another connecting large mortar plate 112 bending. Depend on image 3 As shown, the mutual junctions of a pair of tongue-shaped sealing plates 12, more specifically, the joints in the longitudinal direction of each other are friendly joints, which is like two doors on the same door frame of a building seen in daily life. cooperation relationship. All the other are the same as the description to embodiment 1.

[0026] In summary, the vehicle chain provided by the present invention makes up for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com