Moisture measuring device

The technology of a detection device and a moisture meter, which is applied in the direction of material resistance, can solve problems such as inconvenient loading and unloading, limited installation environment, complex equipment, etc., and achieves the effects of convenient disassembly and maintenance, high detection accuracy and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

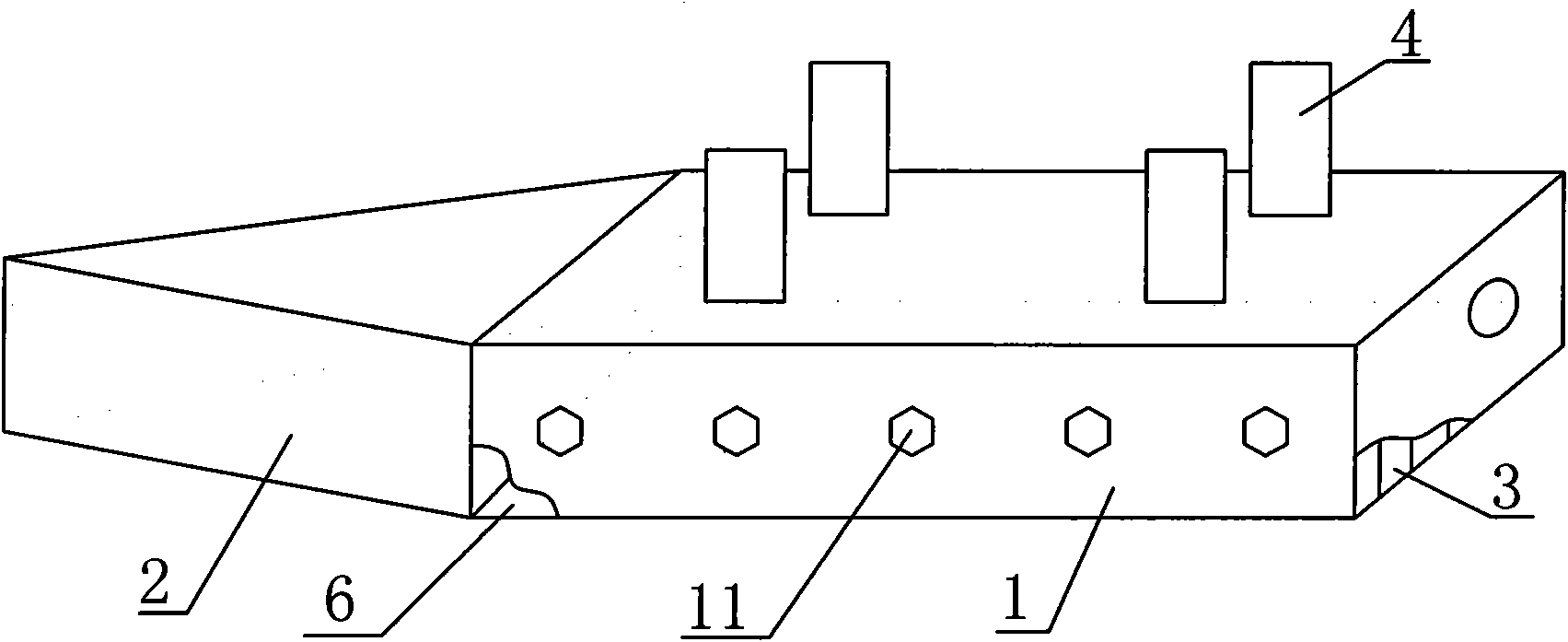

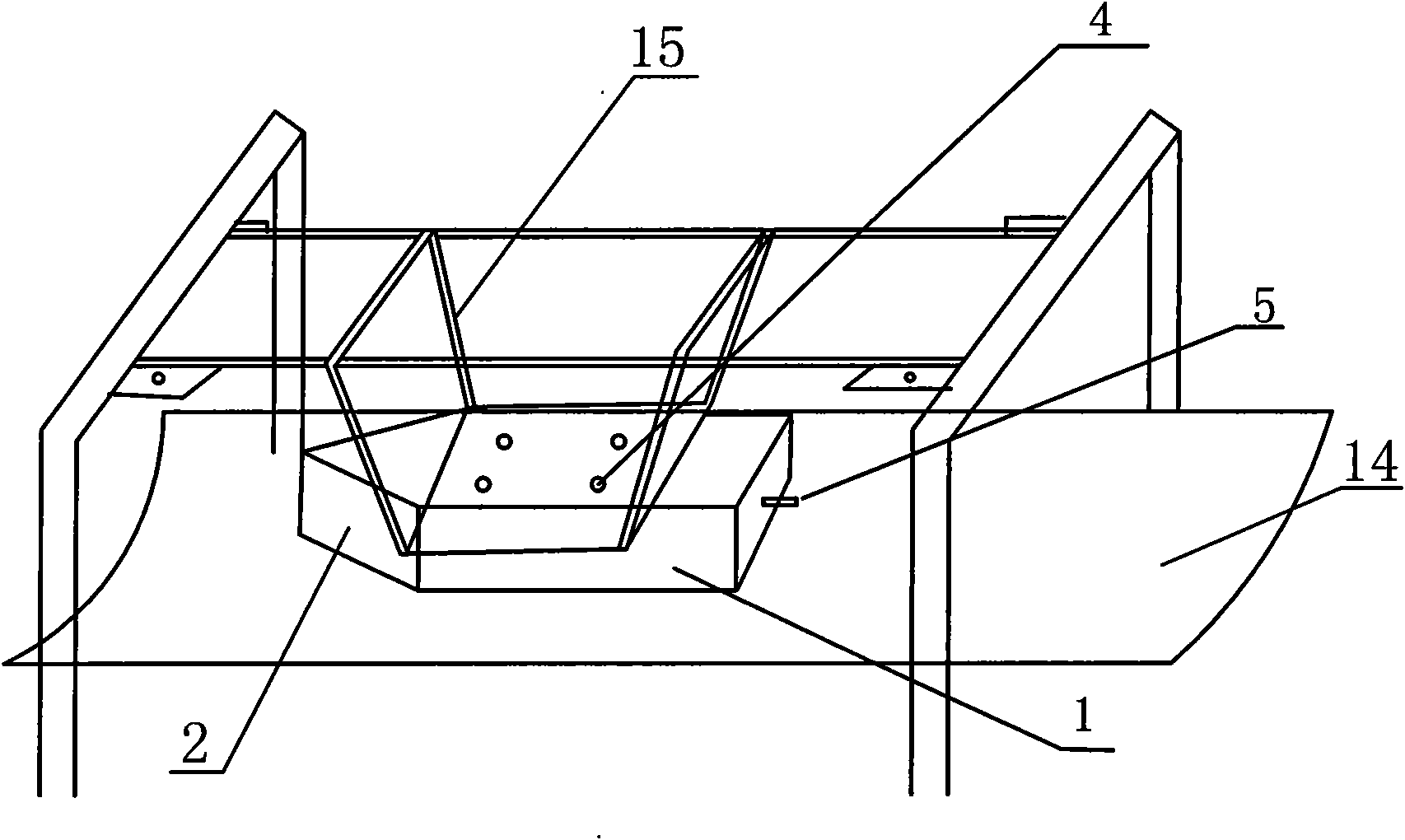

[0026] The moisture meter detection device includes a detection device outer casing 1 , a shunt shaper 2 and an electrode module 3 .

[0027] The lower end of the outer casing 1 of the detection device is an open end, and a plurality of bolts 4 are fixed on the upper surface of the outer casing 1 of the detection device, and an electrode wire socket 5 is fixed on the right end surface of the outer casing 1 of the detection device.

[0028] The shunt shaper 2 is a wedge-shaped body, and its upper and lower end faces are equilateral triangles with the same shape and area. The rear end surface 6 of the shunt shaper 2 is fixedly connected to the front end surface 7 of the outer casing 1 of the detection device.

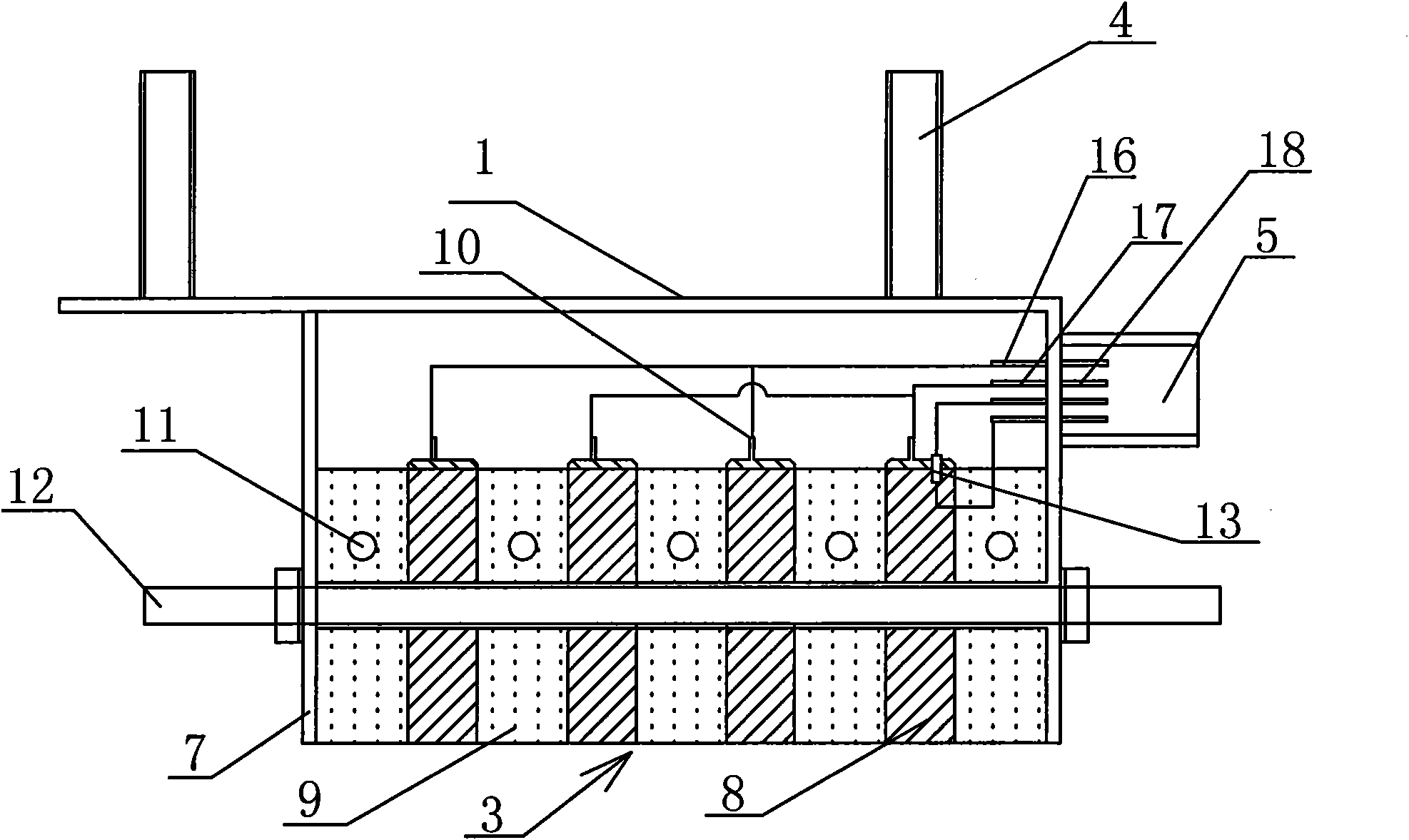

[0029] The electrode module 3 is composed of a conductance electrode assembly and a temperature electrode 13. The conductance electrode assembly includes five ceramic plates 9 arranged in parallel and four metal conduction plates 8 arranged in parallel, and a metal conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com