Protective face shield of ordinary AC welding machine

A technology of alternating current and electric welding machine, which is applied in eye masks and ophthalmic surgery, etc. It can solve the problems of arc stabbing and inability to see the position of the work object clearly, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0014] The first embodiment of the present invention:

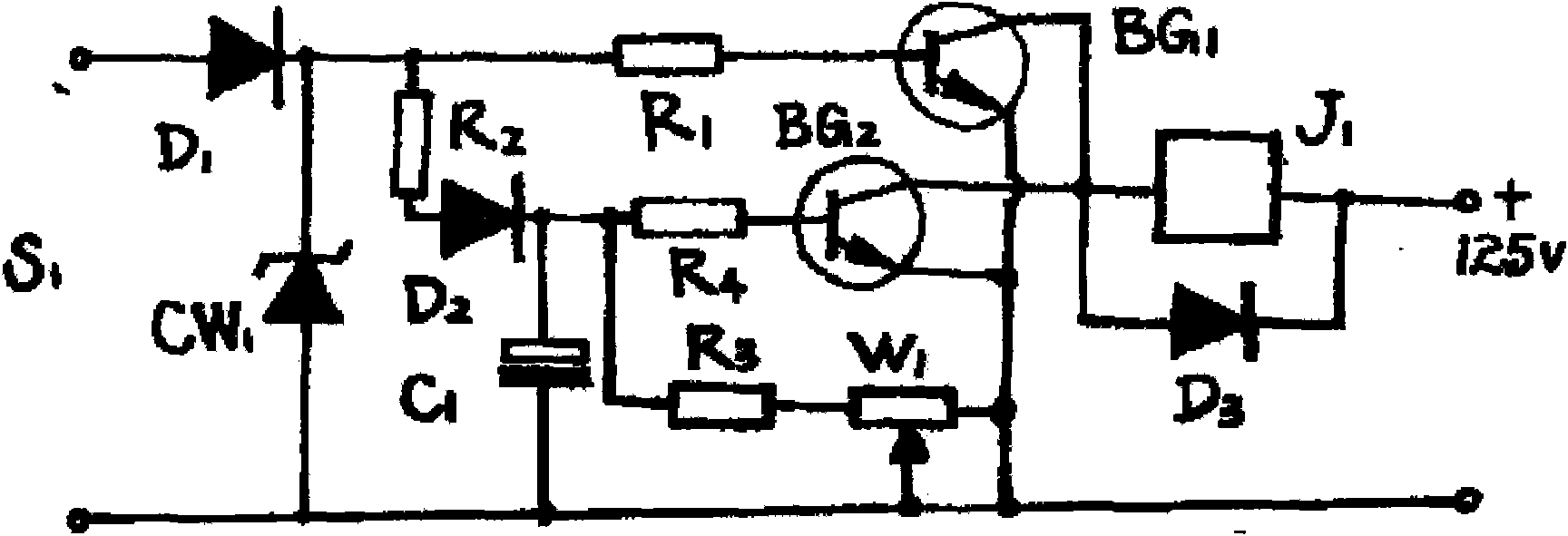

[0015] See figure 1 At the moment when the welding torch is working, the induction probe induces a 4-50 volt AC signal from the welding output line stream. After rectification and voltage stabilization, it is directly applied to BG1 as a base bias voltage through R1 to make BG1 conductive. The breaker J works as an electromagnet that controls the up and down displacement of the welding glass (that is, the color change of the mask), thereby realizing the automation of the mask.

Example

[0016] The second embodiment of the present invention:

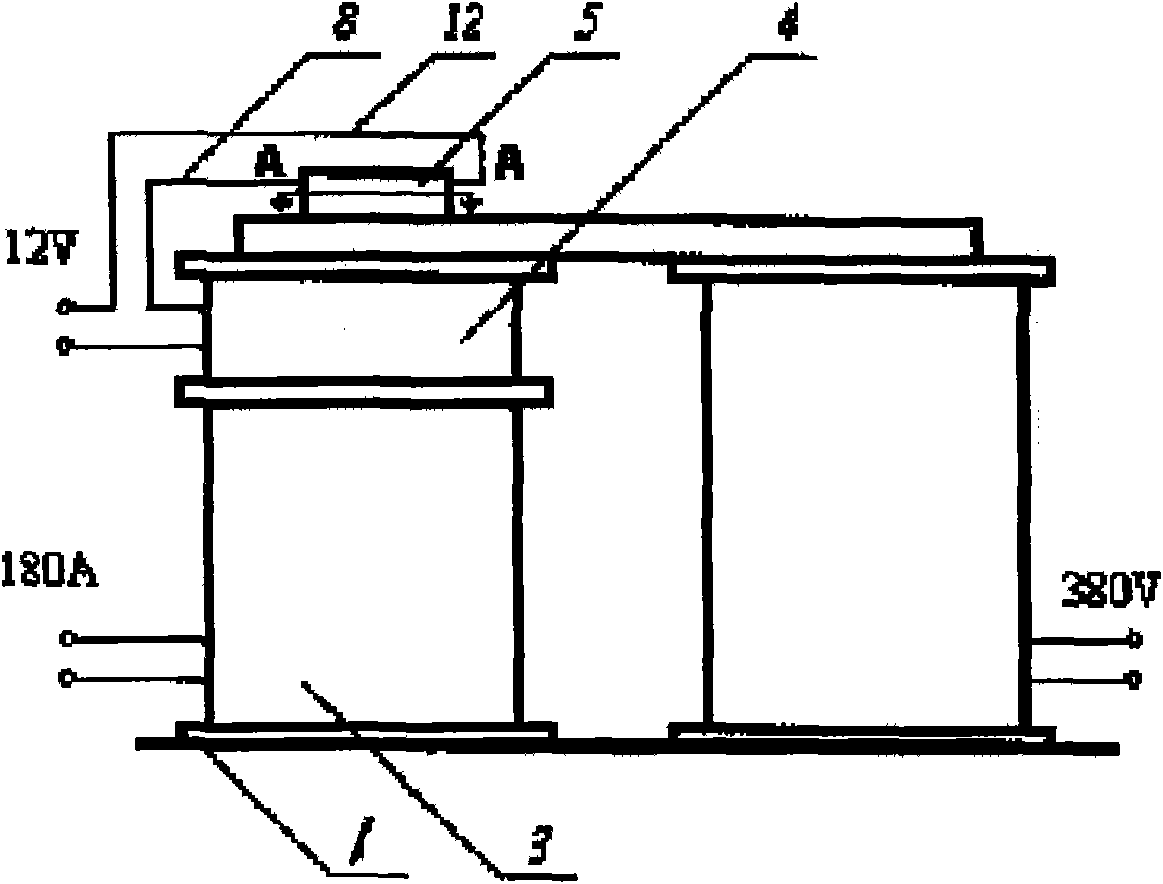

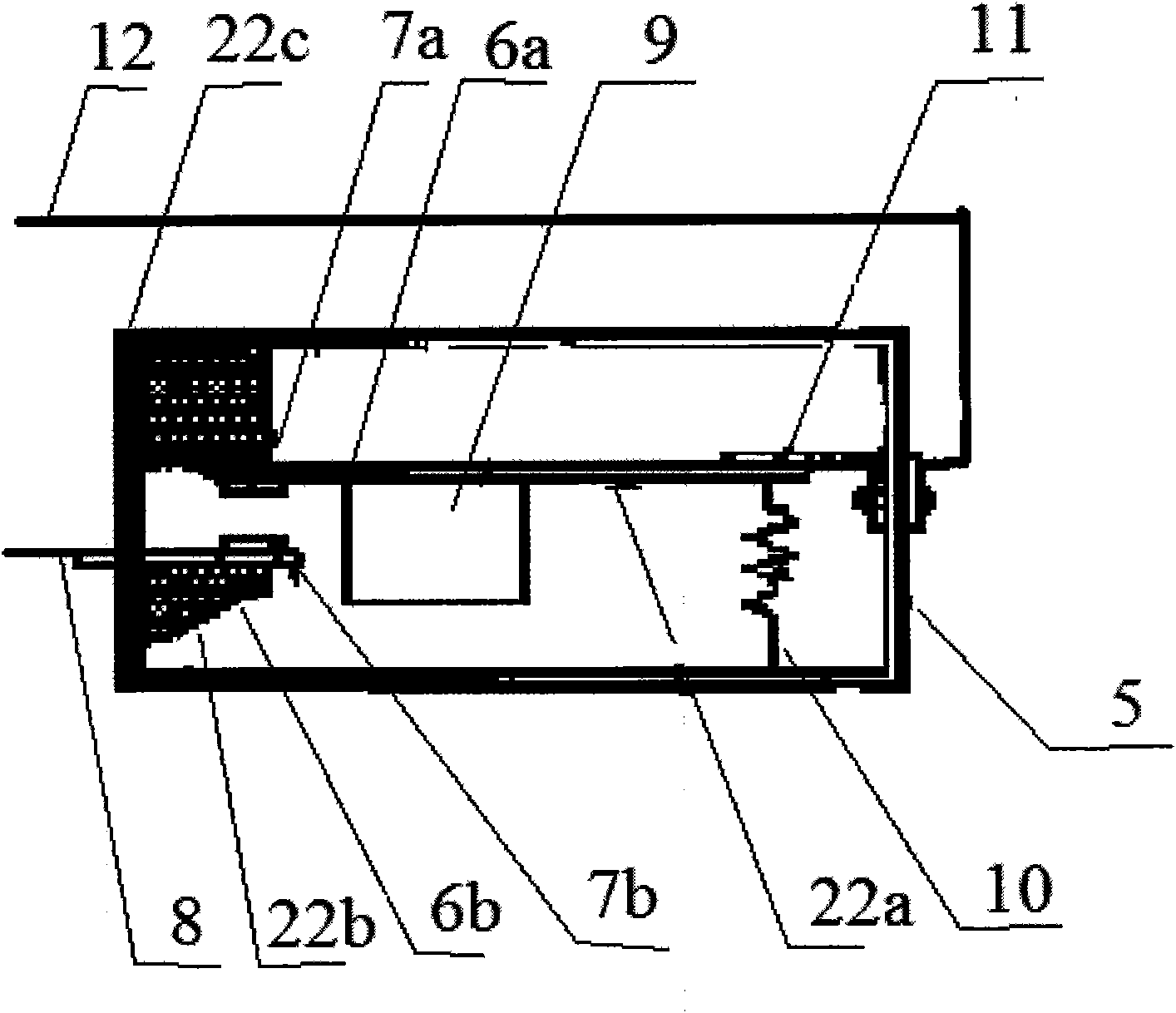

[0017] See figure 1 , 2 6. The present invention is composed of an electric welding machine 1 and a welding cap 2. The upper end of the electric welding machine 1 output H1 coil 3 is separately provided with an attached coil 4 with a voltage of 12V, and a magnetic switch 5 is provided on the outer wall of the electric welding machine 1 The switch is a square box with upper and lower metal sheets 6ab parallel to the bottom surface of the box. The contact bumps 7a on the inner surface of the front end of the ten metal sheets 6a are aligned with the contact bumps 7b on the inner surface of the lower metal sheet 6b. The sheet 6b is connected to the wire 8 at the other end of the outside of the box. The upper metal sheet 6a is provided with a square iron sheet 9 in the center of the inner surface. A spring 10 is provided between the inner surface of the upper metal sheet 6a and the bottom surface of the box. The positioning shee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap