Thick film type antirust coating and preparation method thereof

An anti-rust coating and anti-rust pigment technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of difficult epoxy coatings, stable curing, whitening, etc., to achieve good mechanical properties and anti-corrosion properties, The effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In the embodiments, the following abbreviations or pronouns are adopted:

[0050] YD-128 epoxy resin E1

[0051] YD-75 epoxy resin E2

[0052] BS-F bisphenol F type epoxy resin

[0053] P-BLACK iron oxide black pigment

[0054] BISPHENOL A Diphenolic Propane

[0055] PETROLEUM RESIN petroleum resin

[0056] THIX-1 Hydrogenated castor oil type thickening additive 1

[0057] THIX-2 Polyamide Wax Thickening Additive 2

[0058] E-10 Branched chain alkane hydroxycarboxylate glycidyl ester

[0059] TiO 2 Rutile Titanium Dioxide

[0060] SiO 2 Silicon Dioxide

[0061] TALC talcum powder

[0062] BASO 4 Barium sulfate

[0063] XYL ENE Xylene

[0064] IBA isobutanol

[0065] MXDA m-xylene

[0066] JEF-T Polyetheramine

[0067] Hie-54 Epoxy curing accelerator available from KEUMJUNG

[0068] BENZYLALCOHOL benzyl alcohol

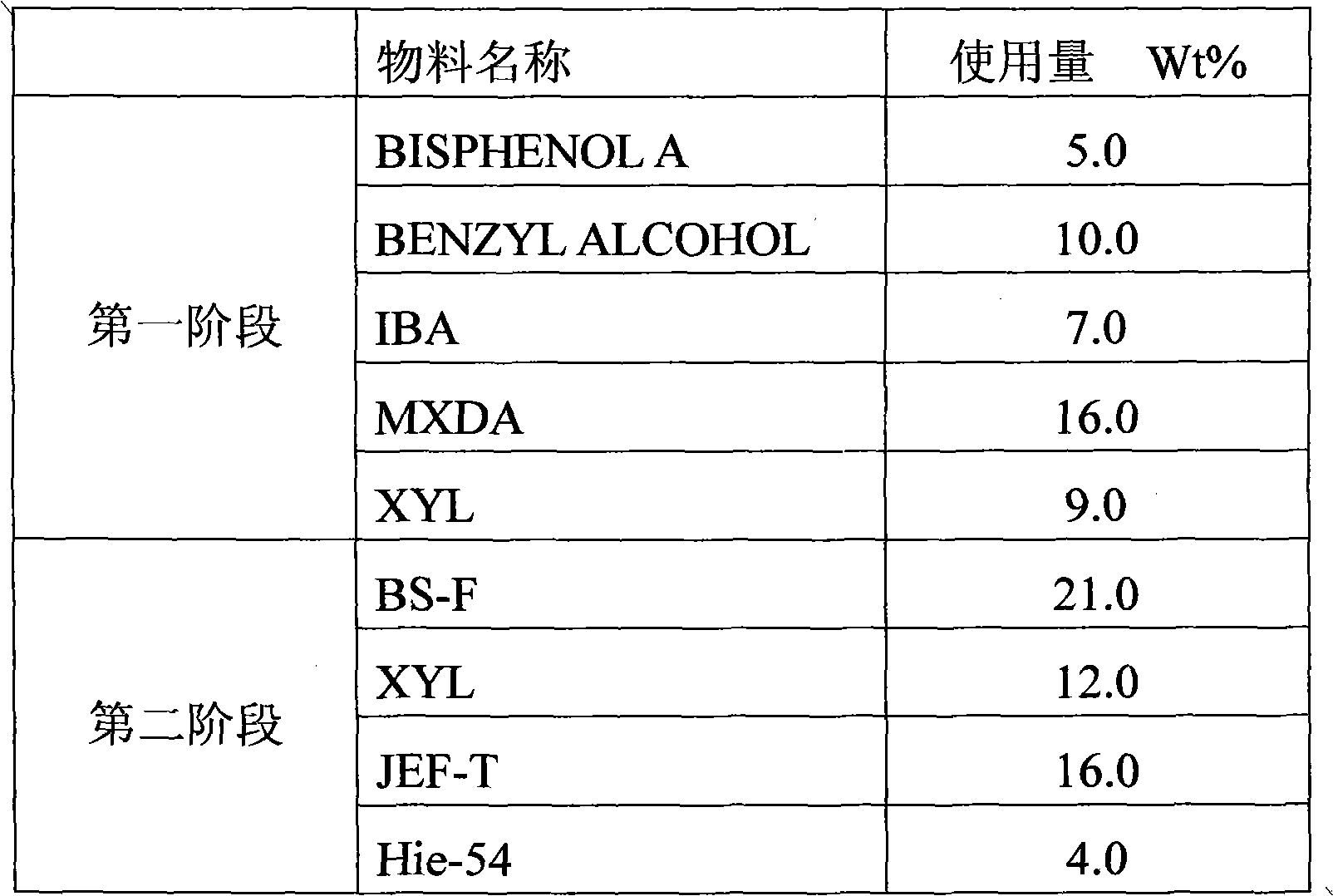

[0069] Table 1 The first component formula table

[0070] Material name

Usage Wt%

BENZYL ALCOHOL

...

Embodiment 2

[0095] Weigh the components in Table 4, Table 5 and Table 6 corresponding to Example 2.

[0096] (1) Preparation of the first component base coating: heat epoxy resin, petroleum resin, anti-rust filler, anti-rust pigment and base coating solvent to 40°C-70°C, stir and mix evenly.

[0097] (2) Preparation of the second component curing agent: heat the epoxy resin, aromatic diamine, and curing agent solvent to 90° C. to 100° C., stir and mix evenly.

[0098] (3) Prepare the third component diluent: mix the aromatic hydrocarbon and alcohol evenly at room temperature.

[0099] Weigh the first component base paint, the second component curing agent and the third component diluent prepared above according to the mass ratio of 85:15:3, stir and mix evenly.

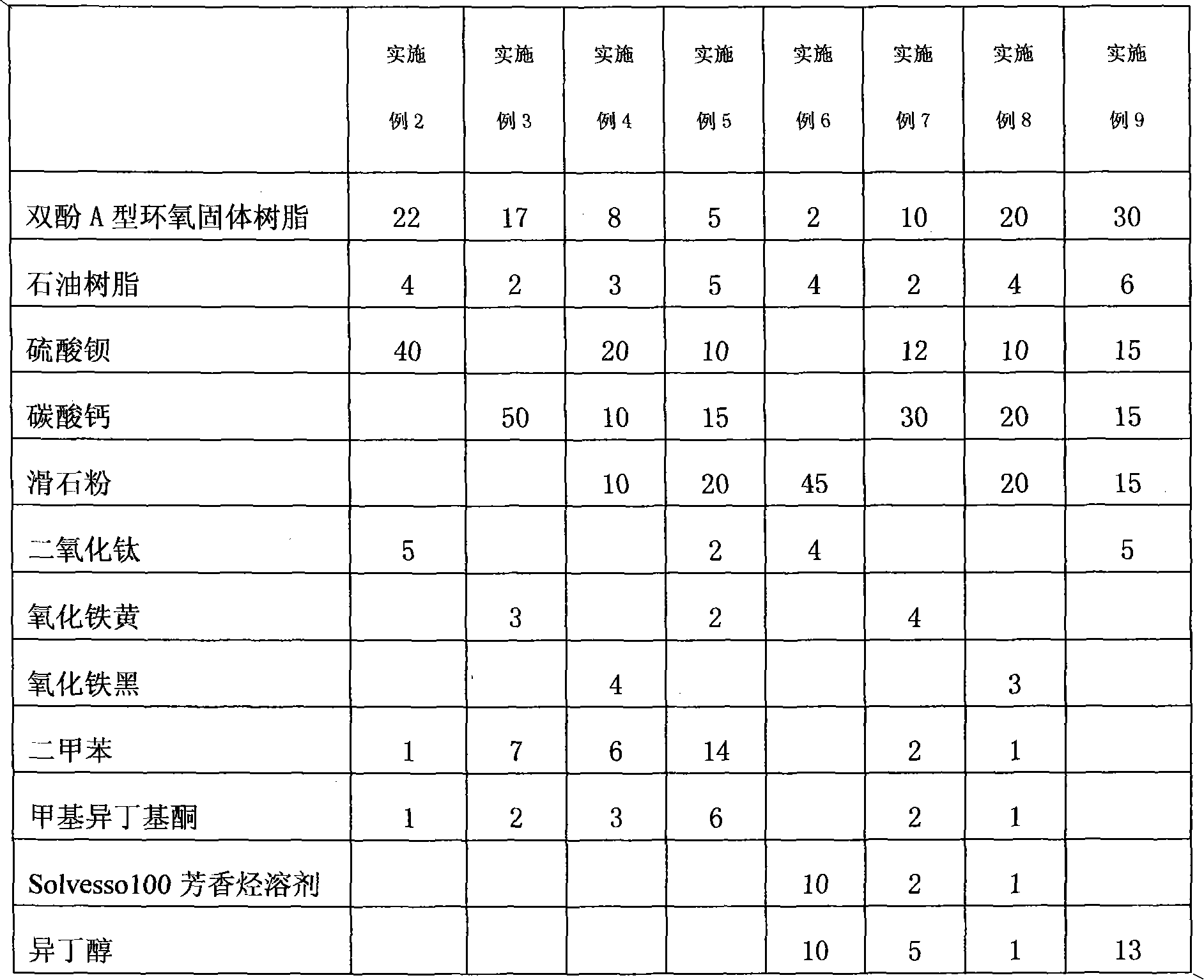

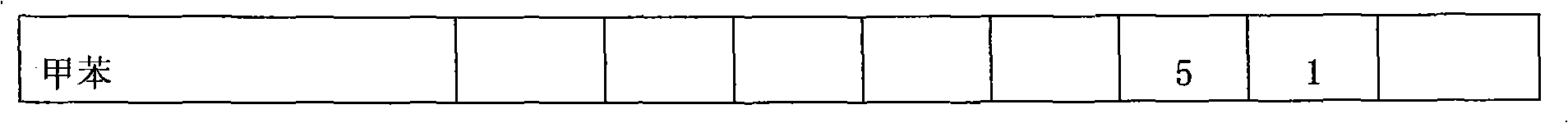

[0100] Table 4 Thick-film anti-rust coating first component matrix coating component list Unit: kg

[0101]

[0102]

[0103] Table 5 Formulation of the second component curing agent for thick film antirust coatings Unit:...

Embodiment 3

[0108] Weigh the components in Table 4, Table 5 and Table 6 corresponding to Example 3. The method in Example 2 was used to prepare the first component base paint, the second component curing agent and the third component diluent respectively.

[0109] Weigh the first component base coating, the second component curing agent and the third component diluent prepared above according to the mass ratio of 87:12:3, stir and mix evenly. The thick-film antirust paint of the present invention can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com