Hollow glass window of buckle type aluminum wood composite profile framework

A technology of composite profiles and aluminum alloy profiles, which is applied to the installation of wing frames, window glass, parallel glass structures, etc., can solve the problems of splitting and loosening, user loss, and inconvenient disassembly of replacement frames, and achieve the effect of avoiding distortion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

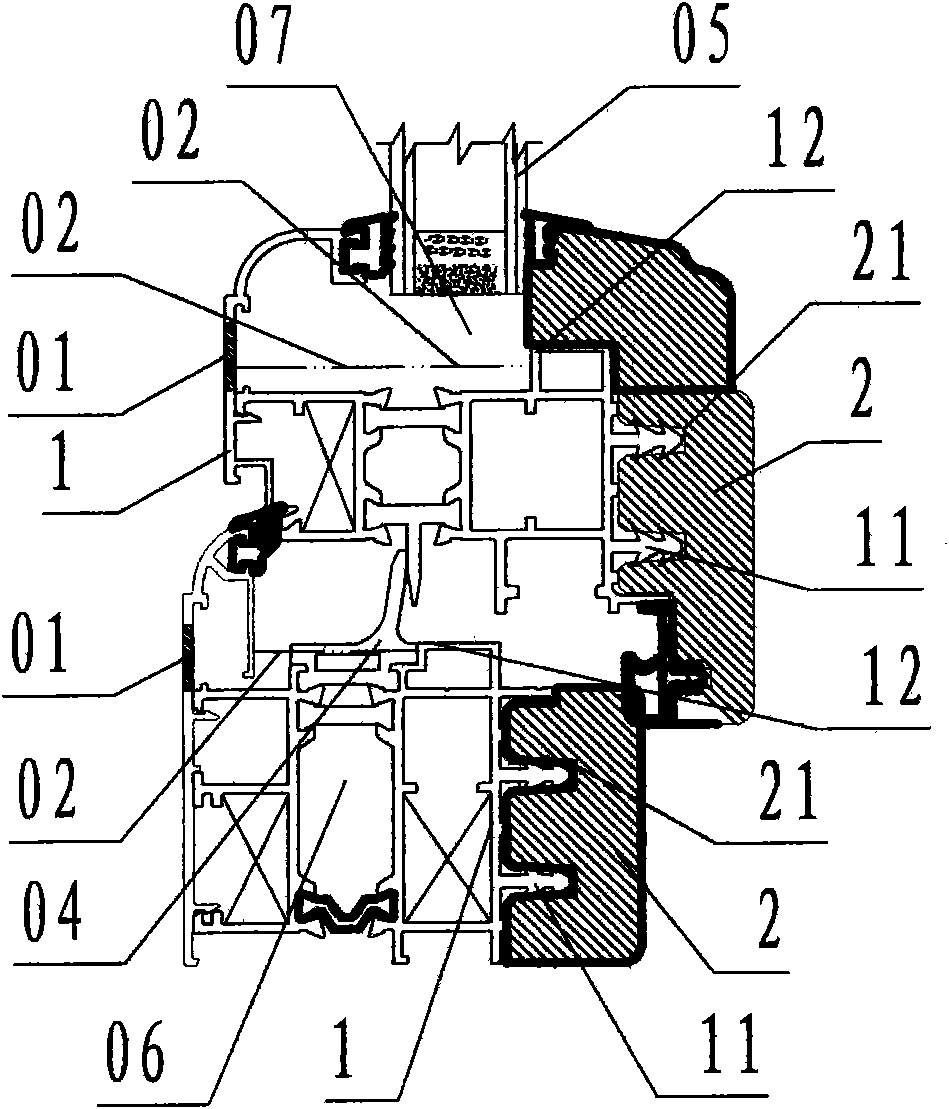

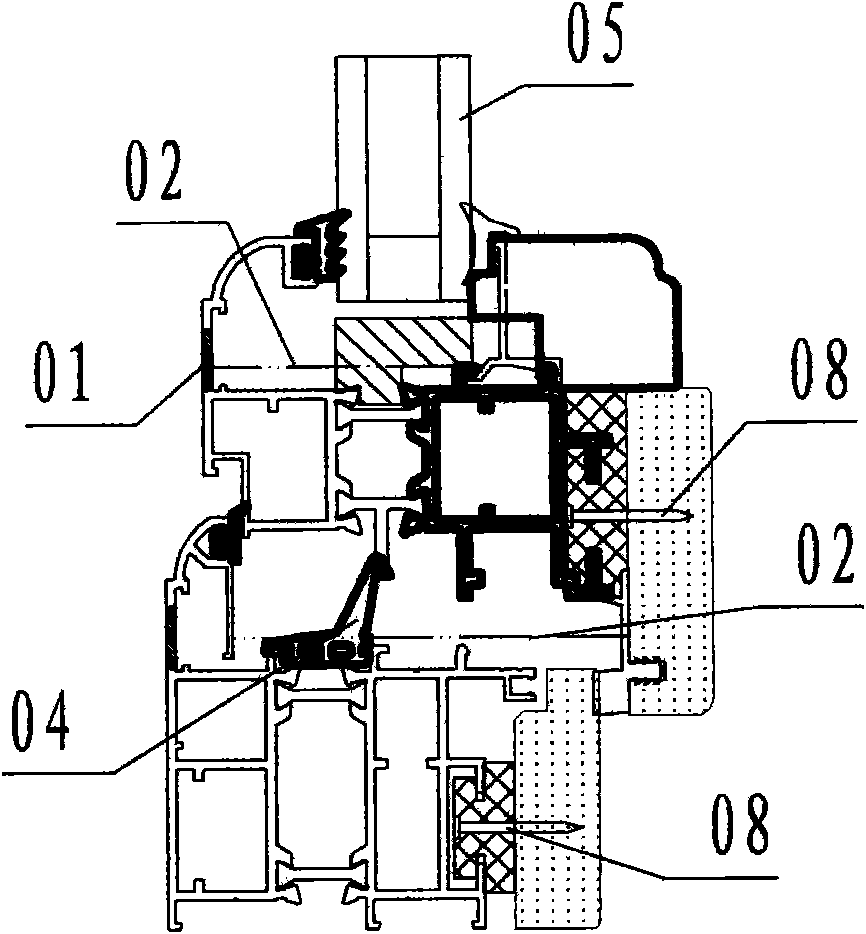

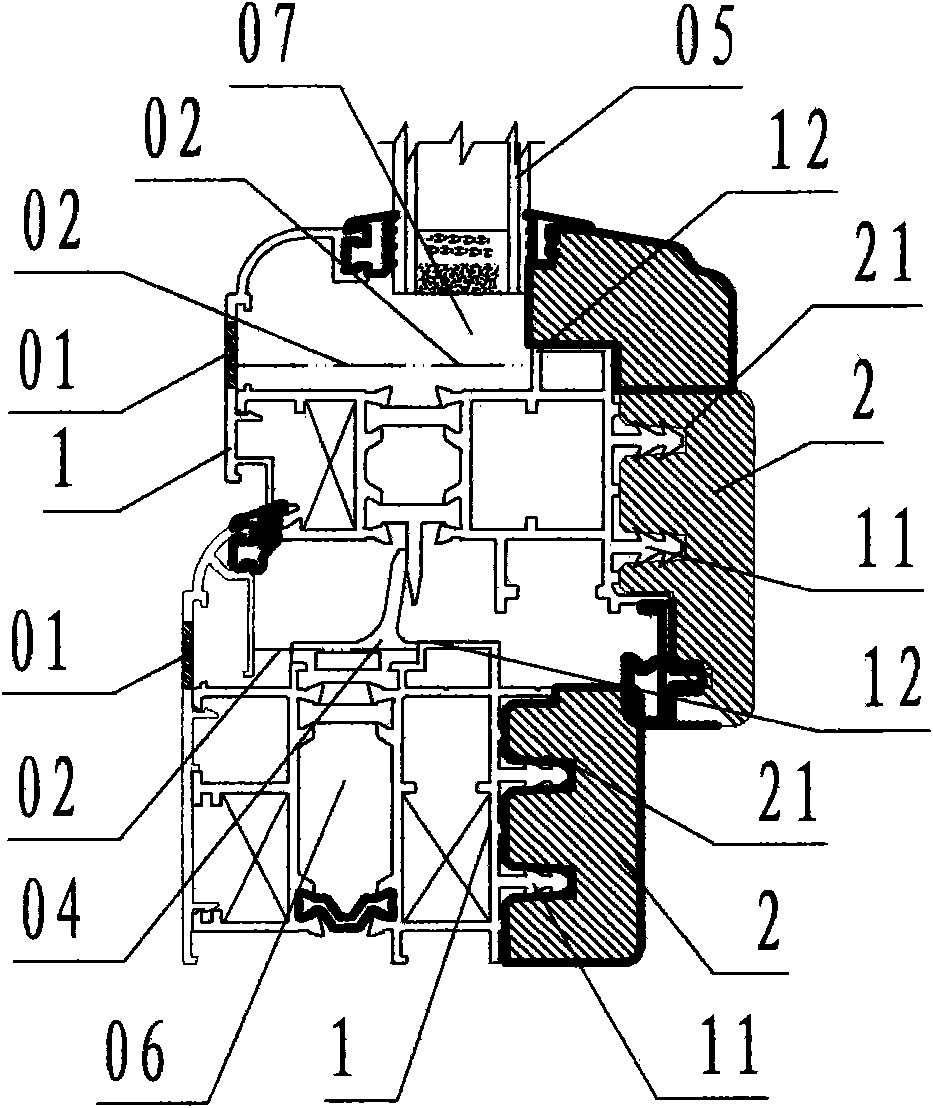

[0019] refer to figure 1 , a gusset-type aluminum-wood composite profile frame hollow glass window of the present invention, comprising a gusset-type aluminum-wood composite profile and an insulating glass 05, wherein: the gusset-type aluminum-wood composite profile is composed of an aluminum alloy profile 1 and a wooden profile 2 The composite aluminum-wood composite profile is connected and combined through the tenon rail 11 and the tenon groove 21; wherein, the aluminum alloy profile 1 is the aluminum alloy part of the aluminum-wood composite profile that constructs the frame of the window frame 06 and the window sash 07, and is formed by a drawing process. The long hollow thin-walled aluminum alloy profile made; the aluminum alloy profile 1 includes the aluminum alloy profile 1 for window frame 06 and sash 07; the aluminum alloy profile 1 for window frame 06 is used to construct the inner frame of window frame 06 On one side, along the drawing direction of the aluminum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com