Steam dryer

A dryer and steam technology, applied in the direction of drying solid materials, non-progressive dryers, drying, etc., to achieve the effect of improving filling degree, increasing contact area and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

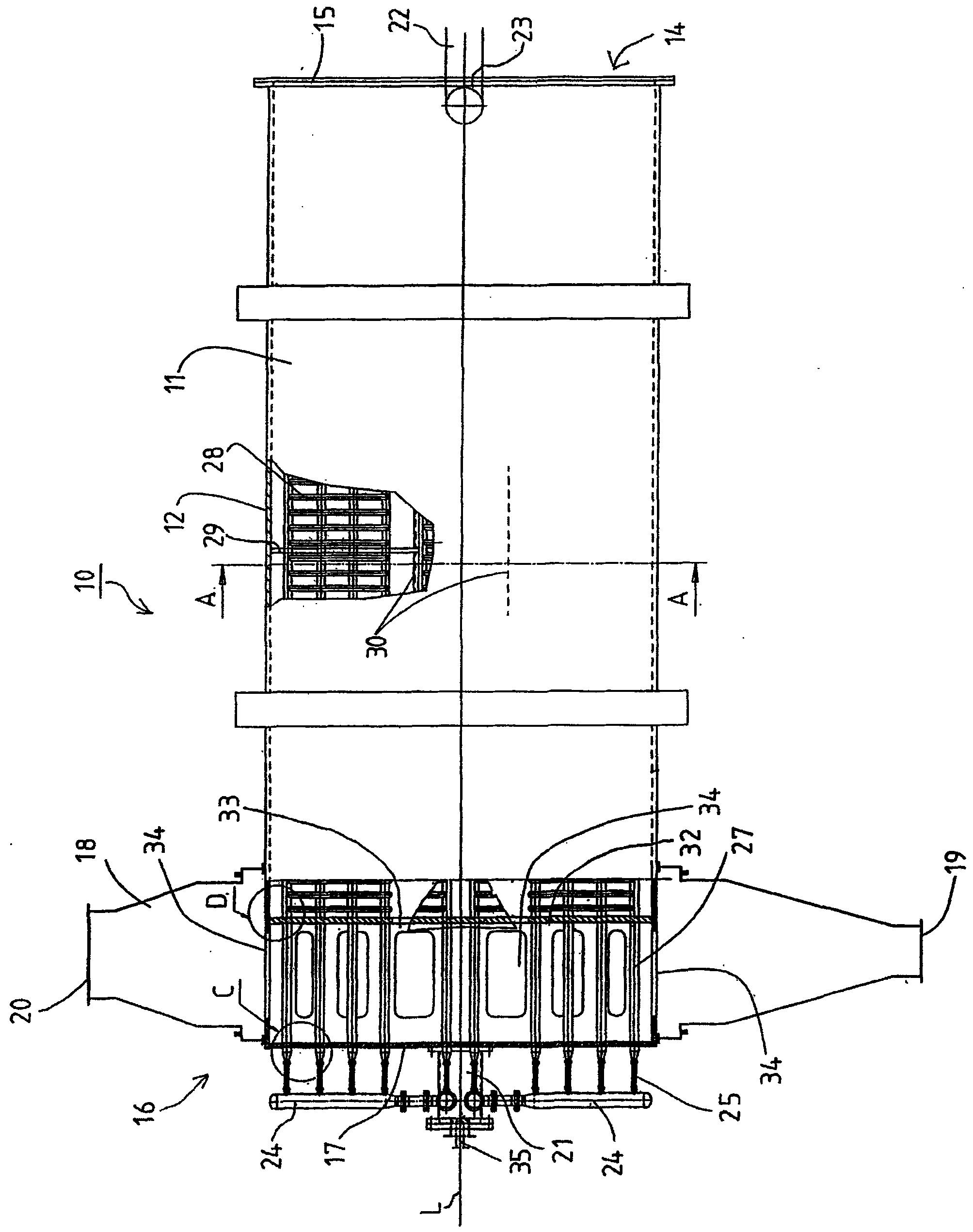

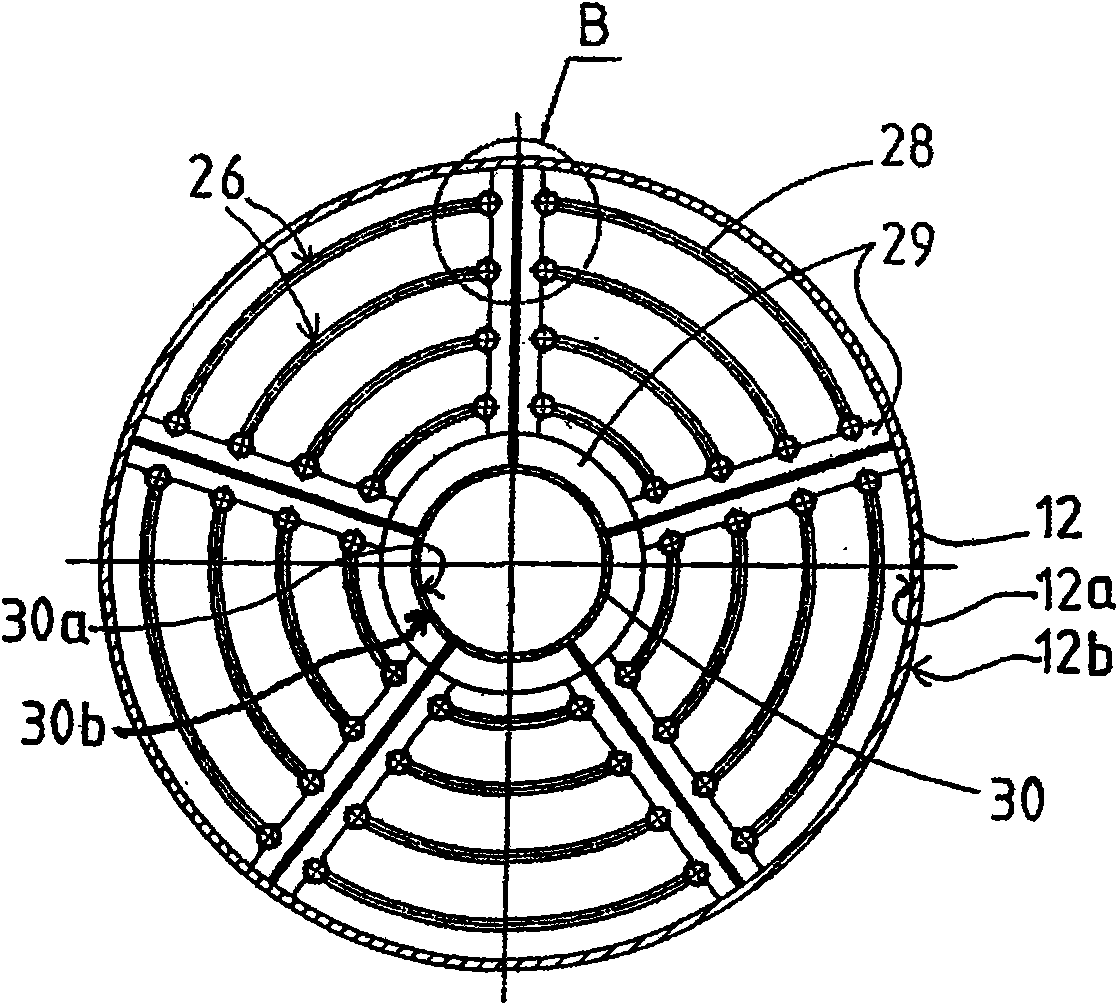

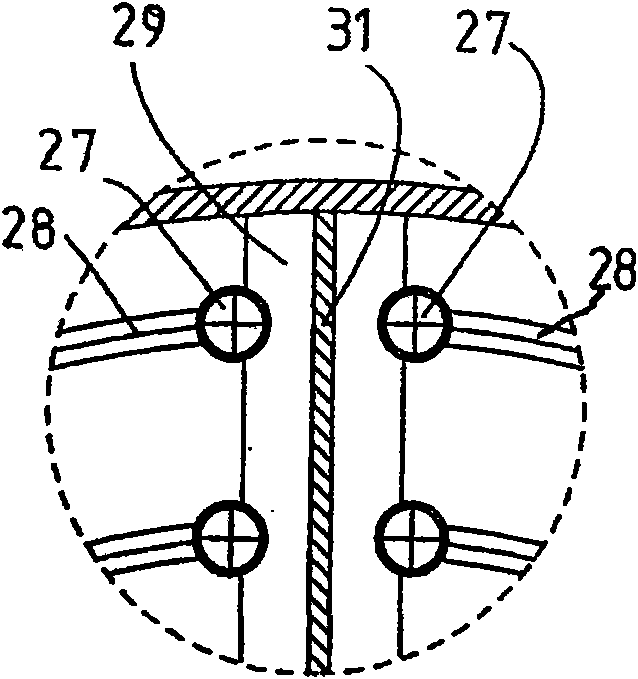

[0030] figure 1 A medium steam dryer is indicated generally by the reference numeral 10 . The steam dryer 10 comprises a cylindrical rotatable drum 11 having an outer shell 12 with an inner surface 12a and an outer surface 12b. The steam pipe member 26 is installed inside the drum 11 to rotate with the drum 11 . The drum 11 has a feed end 14 constructed and arranged to receive wet or liquid material into said drum 11 , the feed end 14 being defined by a feed end plate 15 . The drum 11 also has a discharge end 16 constructed and arranged to discharge off-gas and dry material or residual liquid from said drum 11 , the discharge end 16 being defined by a discharge end plate 17 .

[0031] The fixed end chamber 18 is configured and arranged axially between the discharge end plate 17 and the feed end plate 15 of the drum 11 in the area of the discharge end 16 such that the discharge end plate 17 is located at the The outside of the discharge end chamber 18. Such as figure 1 Sai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com