High-precision joining method of uneven surface object picture

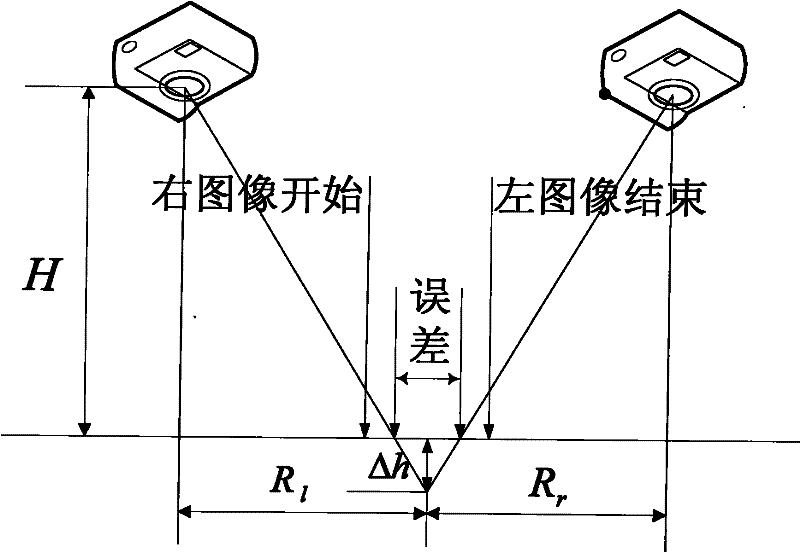

A technology with uneven surface and high precision, applied in image data processing, instruments, calculations, etc., can solve problems such as stitching errors, and achieve the effect of eliminating stitching errors and improving stitching accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] A specific implementation of the present invention will be described in detail below with reference to examples.

[0065] (1) According to the overlapping area in the first image and the second image that need to be spliced, the structured light three-dimensional scanner is used to obtain the five-tuple (x w , Y w ,z w , U r , V r );

[0066] The first image and the second image here are obtained by photographing surface concave-convex objects, and have a partial overlap area. During three-dimensional scanning, it is required to cover at least the part of the surface concave-convex object corresponding to the overlap area to facilitate error correction.

[0067] In the five-tuple, (x w , Y w ,z w ) Is the coordinate of the sampling point in the three-dimensional space (world coordinate system), (u r , V r ) Is the coordinate of the sampling point in the first image;.

[0068] (2) Fitting of the best reprojection plane based on the least square method

[0069] Assuming that the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com