Assembly device, set of two parts assembled by such a device and warp frame of a machine for forming the shed including such a set

A technology of fastening device and forming machine, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve problems such as incompatibility, and achieve the effect of compact device and suitable for disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

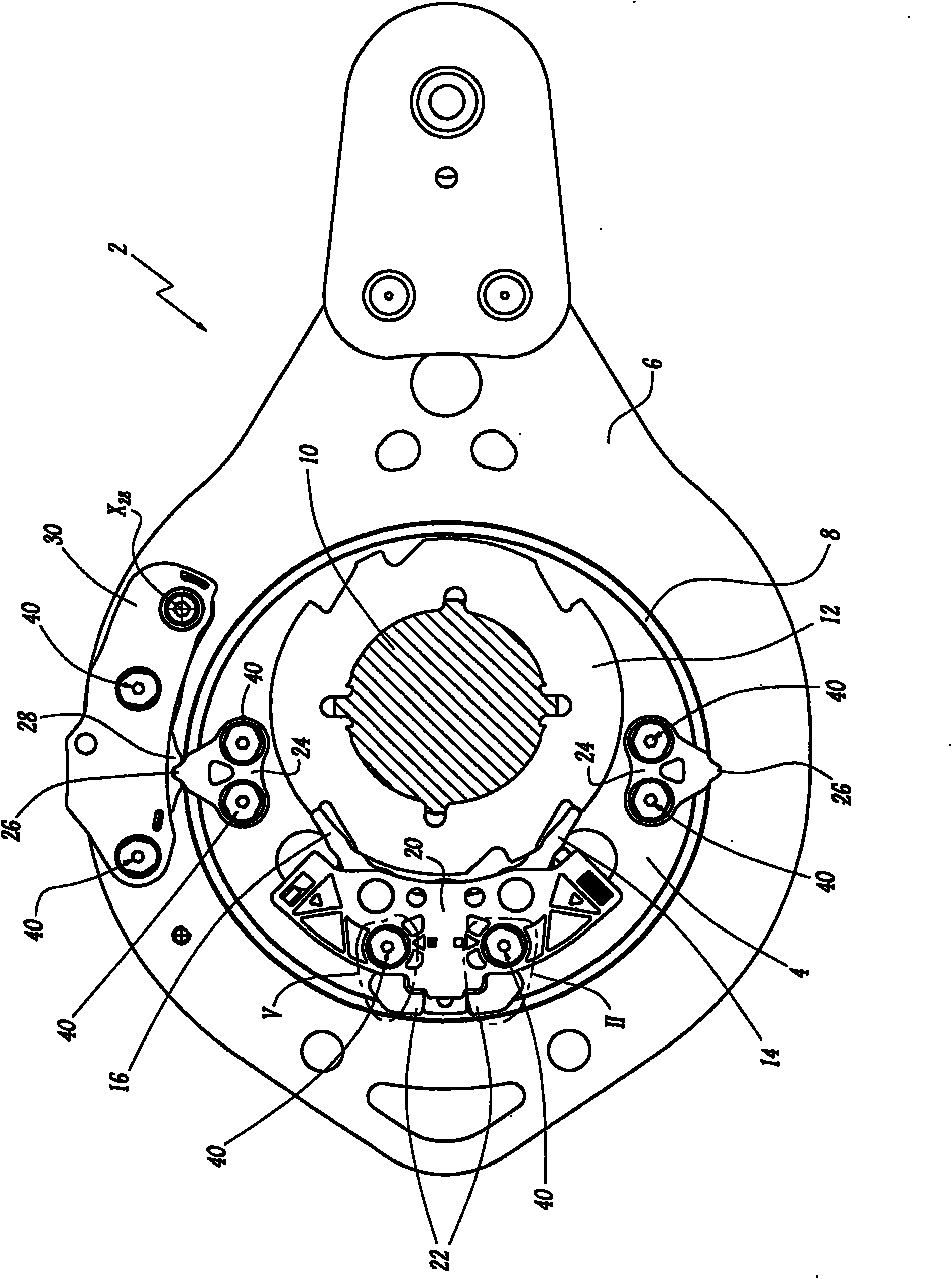

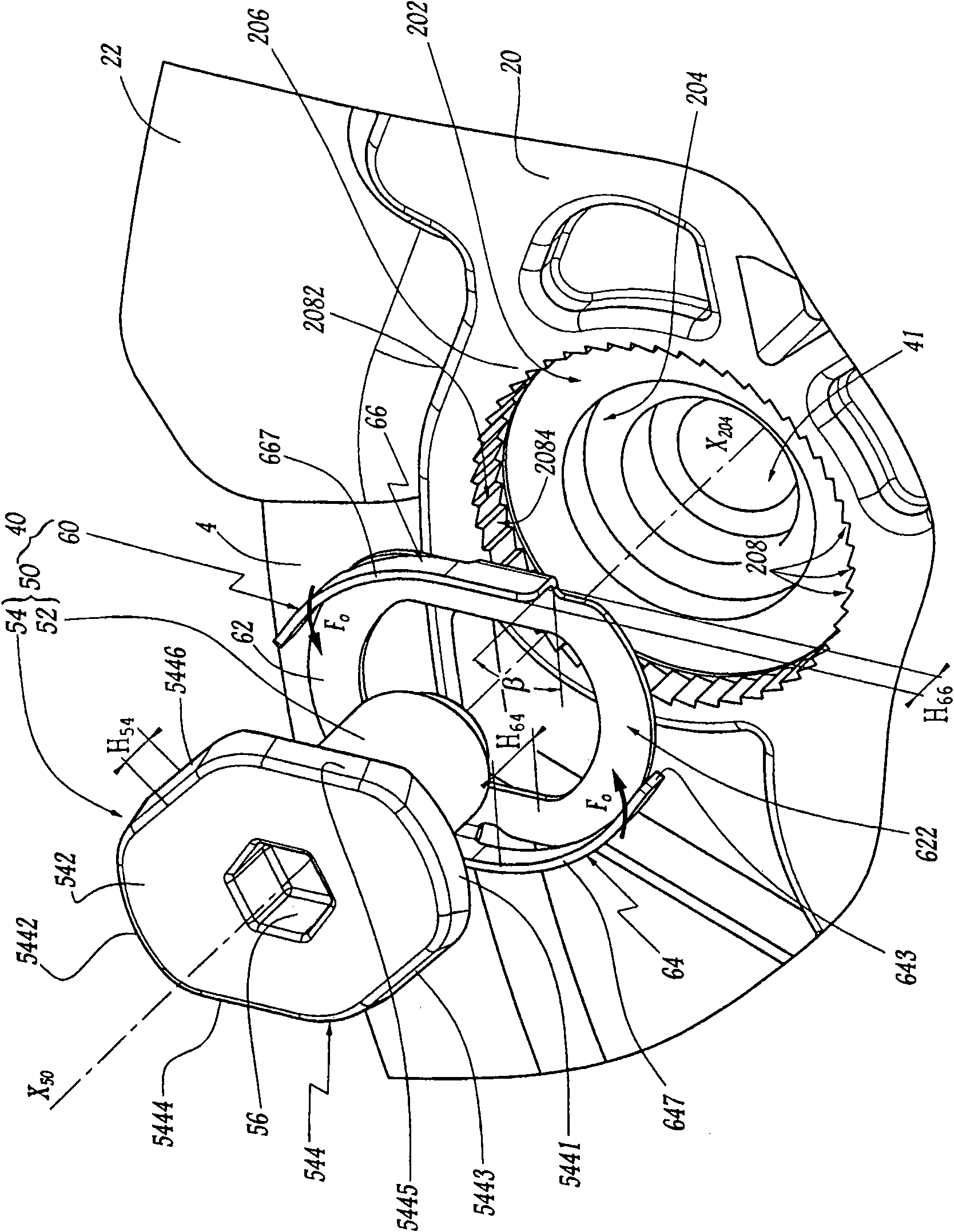

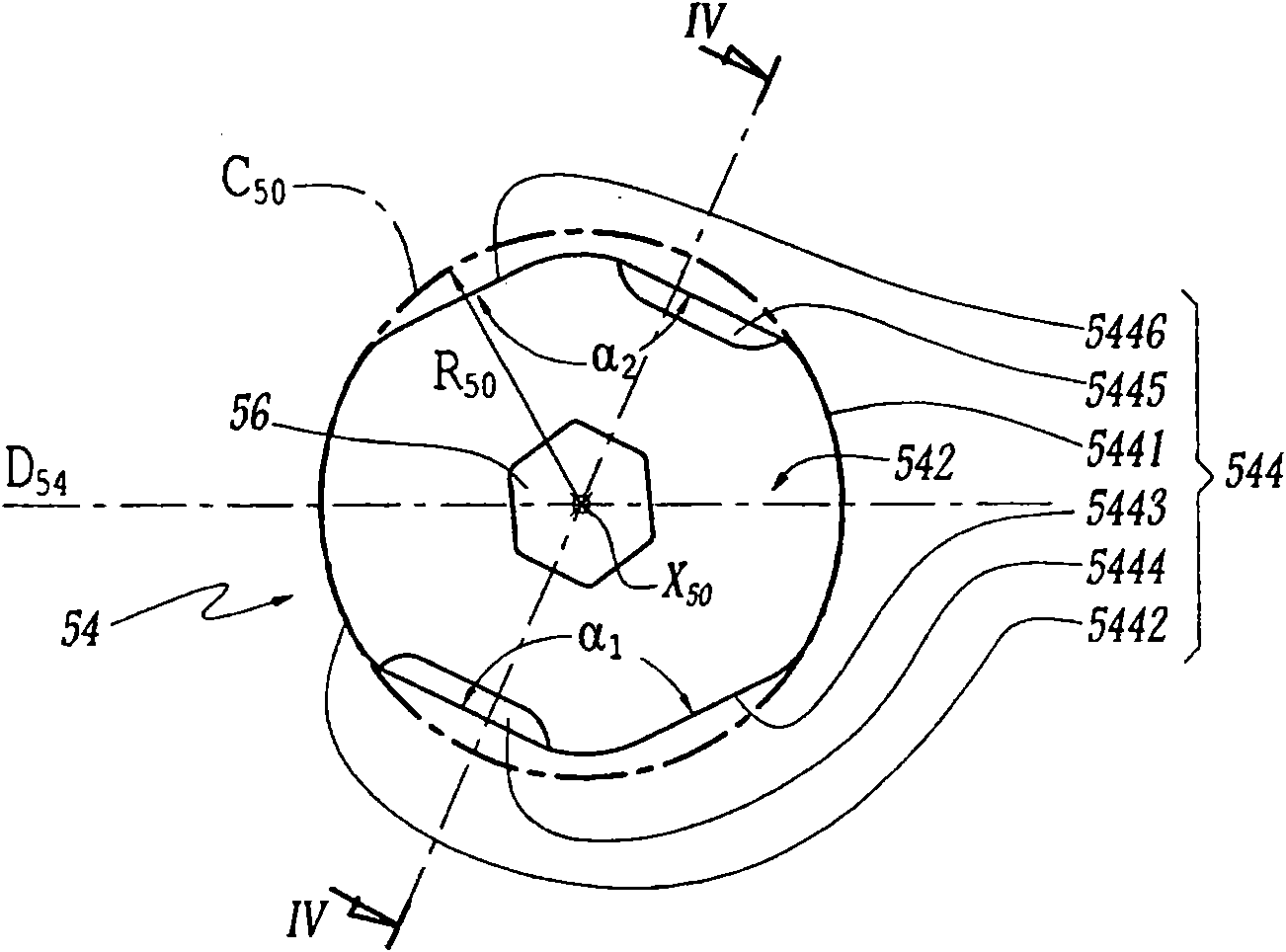

[0030] figure 1 A part of the heald frame lifting unit 2 shown in includes an eccentric disk 4 with an opening for an oscillating connecting rod 6 movably mounted thereon, with ball bearings 8 arranged between them. The connecting rod 6 is intended to be connected to a pulling mechanism engaged with the heald frame by means (not shown) comprising a pivot arm. The main shaft 10 driven by intermittent rotation rotates together with the drive disc 12 and pauses every half circle. Detents 14 and 16 controlled in a known manner selectively fasten the eccentric disc 4 to the disc 12 according to the movement transmitted to the heald frame. Detent pins 14 and 16 are made by Figure 2-Figure 7 The plastic material cap 20 of the eccentric disk 4 is held against the eccentric disk 4 by two fastening means 40 shown in detail in . Two guide members 22, generally called "ramps", are provided between the cap 20 and the eccentric disc 4, and they protrude radially from the (not shown) ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com