End sampler for planetary exploration

A sampler and planetary technology, applied in the field of space resource detection, can solve problems such as the inability to meet the quality constraints of the detector system, the inability to directly connect the manipulator, and the loss of flexibility, and achieve good motion symmetry, compact structure, and power consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

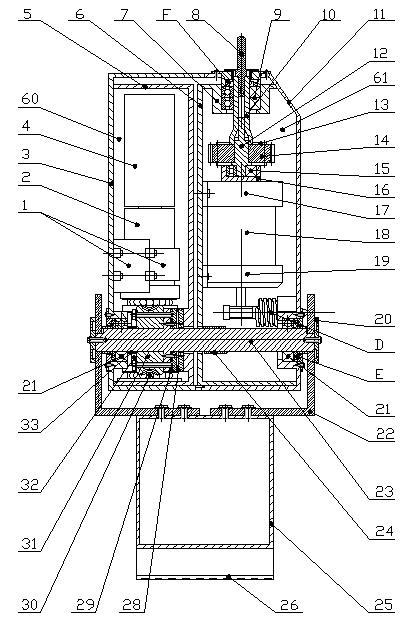

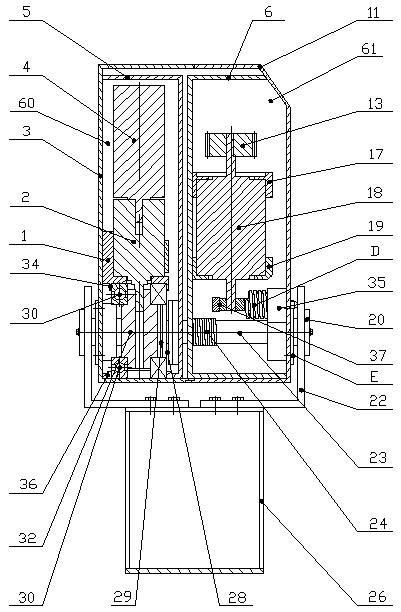

[0009] Specific implementation mode one: combine Figure 1-Figure 4 and Figure 7 , Figure 9-Figure 11 To illustrate this embodiment, the terminal sampler for planetary exploration in this embodiment includes an excavation input device A, an excavation output device B, a first shell 3, a second shell 11, a first inner shell 5, and a second inner shell 6; The first outer shell 3 and the second outer shell 11 are interlocked to form a housing, the first inner shell 5 and the second inner shell 6 are placed in the housing, and the first inner shell 5 and the first outer shell 3 form a first chamber 60, the second inner shell 6 and the second outer shell 11 enclose a second chamber 61;

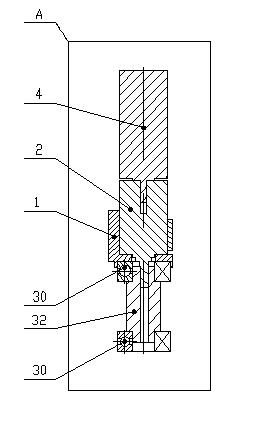

[0010] The excavation input device A is installed in the first chamber 60, and the excavation input device A is composed of the excavation input device support frame 1, the planetary gear reducer 2, the first DC brushless motor 4, the worm 32 and two thrust The ball bearing 30 is composed of t...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 7 Describe this embodiment, the first labyrinth sealing device E of this embodiment is composed of a first outer flange 42, a first sealing ring 43 and a first inner ring 44, and the first outer flange 42 is set in the first inner ring. On the outer shoulder of the ring 44 , the seal between the first outer flange 42 and the first inner ring 44 is sealed by a sealing ring 43 . So arranged, the internal drive and transmission components are protected from planetary surface dust. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 , Figure 5 and Figure 8-Figure 11To illustrate this embodiment, the terminal sampler for planetary detection in this embodiment is also added with a grinding device C, which is composed of a grinding head 8, a second labyrinth sealing device F, and a double angular contact ball bearing. 9. Second sleeve 10, grinding output shaft 12, grinding device input gear 13, grinding device output gear 14, single angular contact ball bearing 15, double output DC brushless motor upper support frame 17, double output DC The brushless motor 18 is composed of a lower support frame 19 of the dual-output brushless DC motor; the upper part of the dual-output brushless DC motor 18 is fixedly installed in the upper support frame 17 of the dual-output brushless DC motor, The bottom of the motor 18 is fixedly installed in the lower support frame 19 of the dual-output brushless DC motor, the upper output shaft of the dual-output brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com