Impact tester of single soldered ball

A tester and single-welding technology, which is applied in impact testing, testing material strength using one impact force, testing of machine/structural components, etc., can solve the problems of lengthy, complicated testing process, low precision, etc., and achieve accurate initial conditions , convenient positioning, and enhanced application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

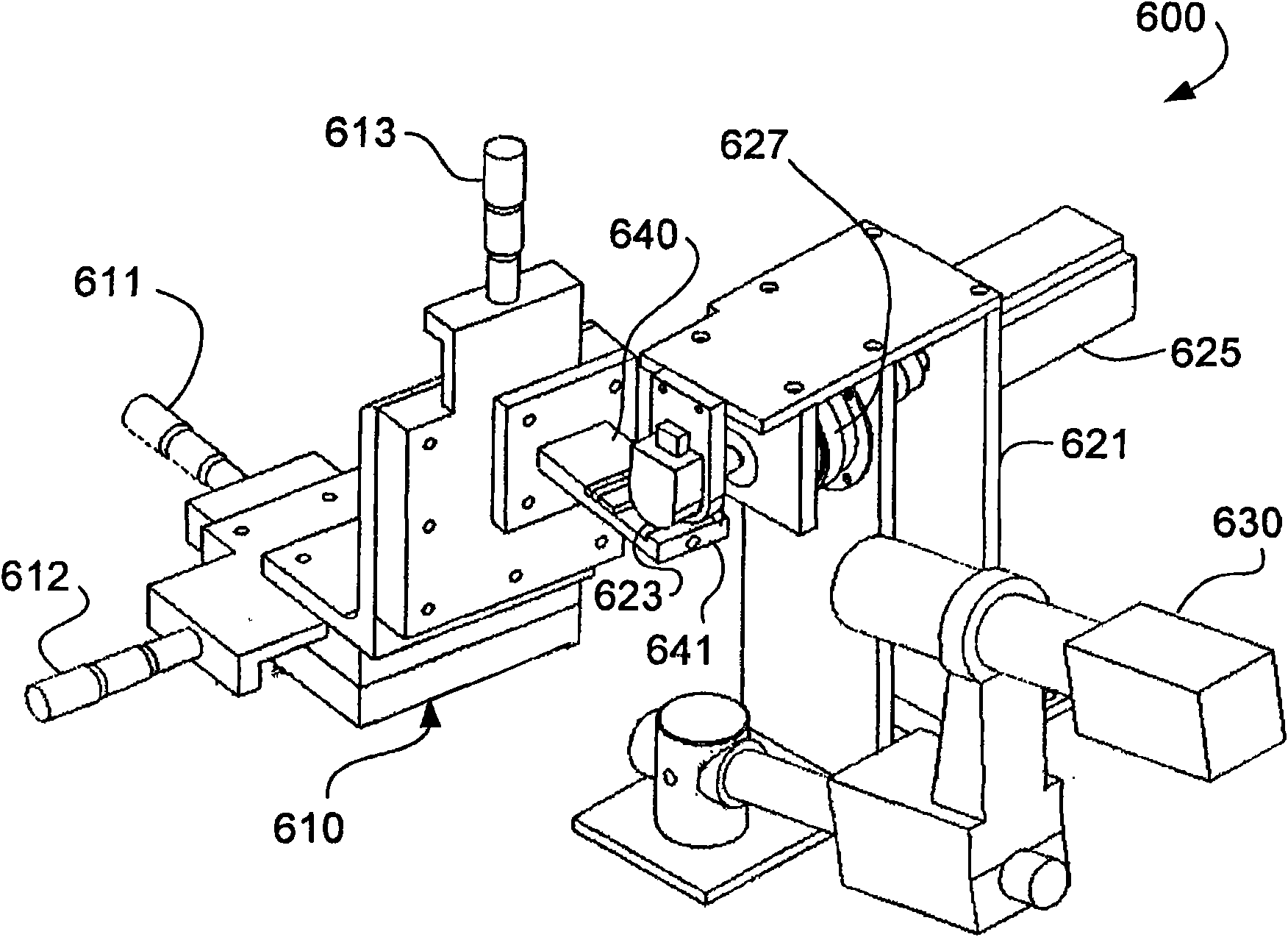

[0039] Such as Figure 1 to Figure 3 Shown is the structure of the existing single solder ball impact tester.

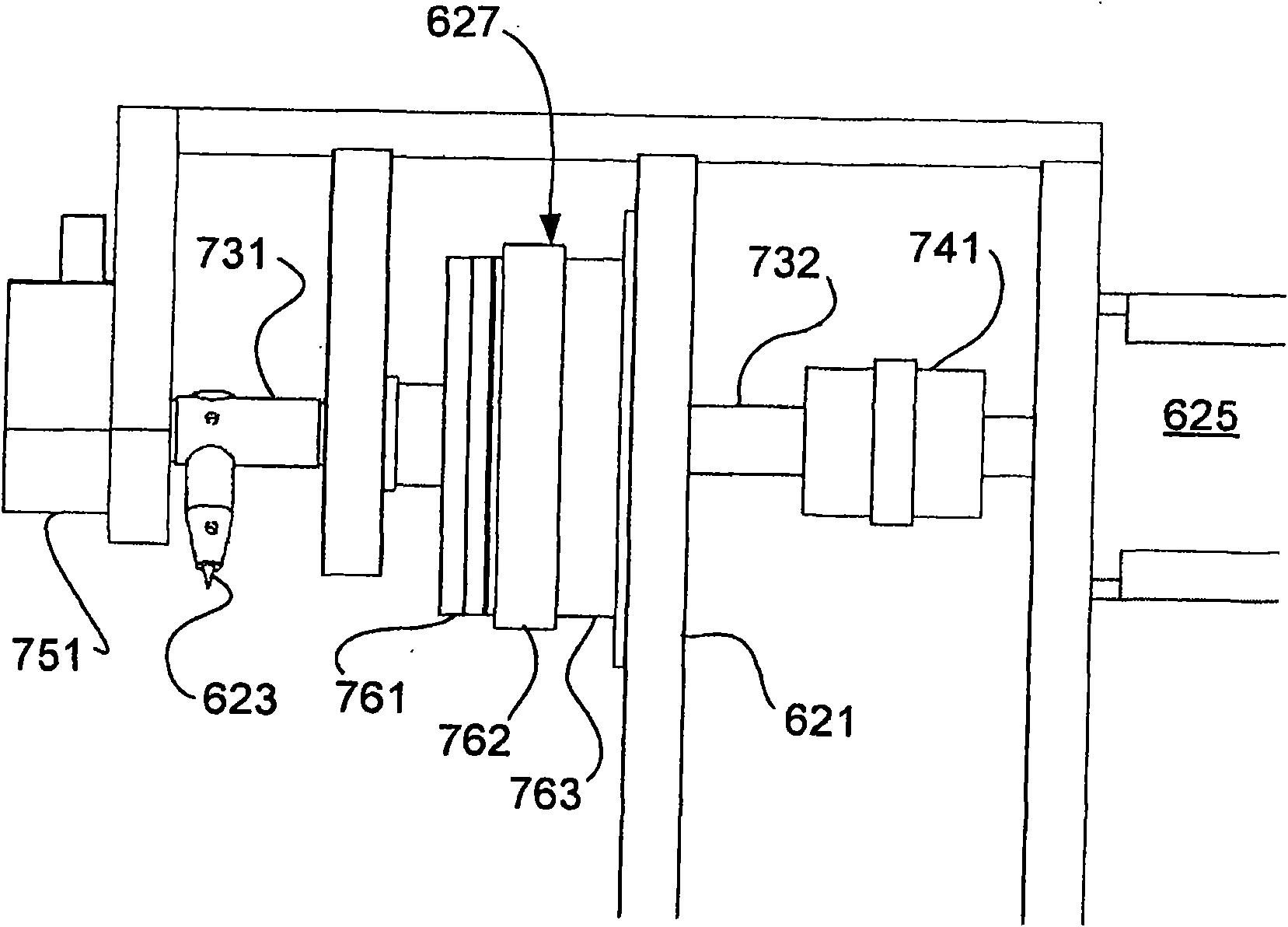

[0040] The single solder ball impact tester of the present invention utilizes the original alignment system XYZ workbench 610 made up of adjustment devices 611, 612, 613, and the XYZ table 610 made up of support members 621, impact heads 623, motors 625 and clutches 627. impact system; and a sampling platform 640 including a fixture 641; a detection system 630 including a solder ball position image monitor; the sampling platform 640 is fixed on the vertical vertical plate of the XYZ worktable adjustment device 613 and extends horizontally.

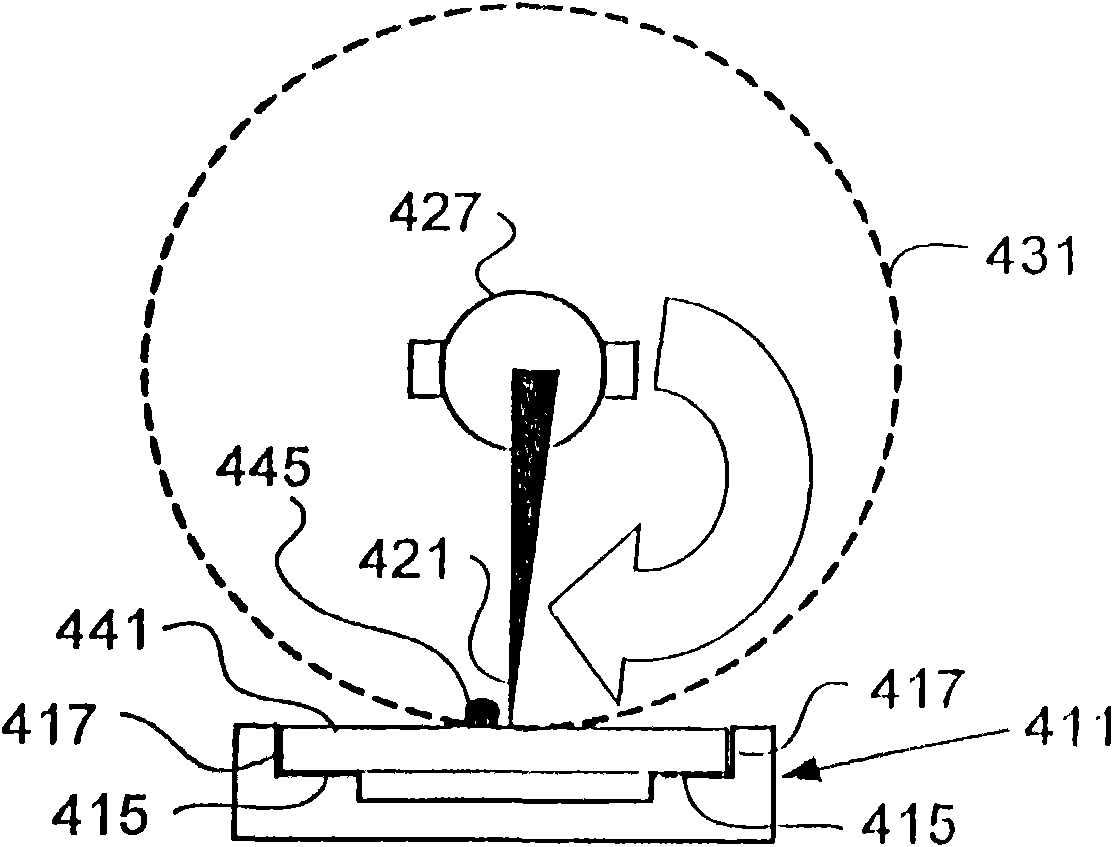

[0041] Such as Figure 4 to Figure 10 As shown, the single solder ball welding shear strength impact tester of the present invention includes an alignment system, an impact system, and a sampling platform system. The alignment system includes an XYZ workbench, and the XYZ workbench is composed of X, Y, and Z adjustment devices T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap