Manufacture method of optical module

A manufacturing method and technology of optical modules, applied in optics, manufacturing tools, nonlinear optics, etc., can solve problems such as the separation of lens structure and glass substrate, the reduction of production yield of birefringent lenses, etc., and achieve the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

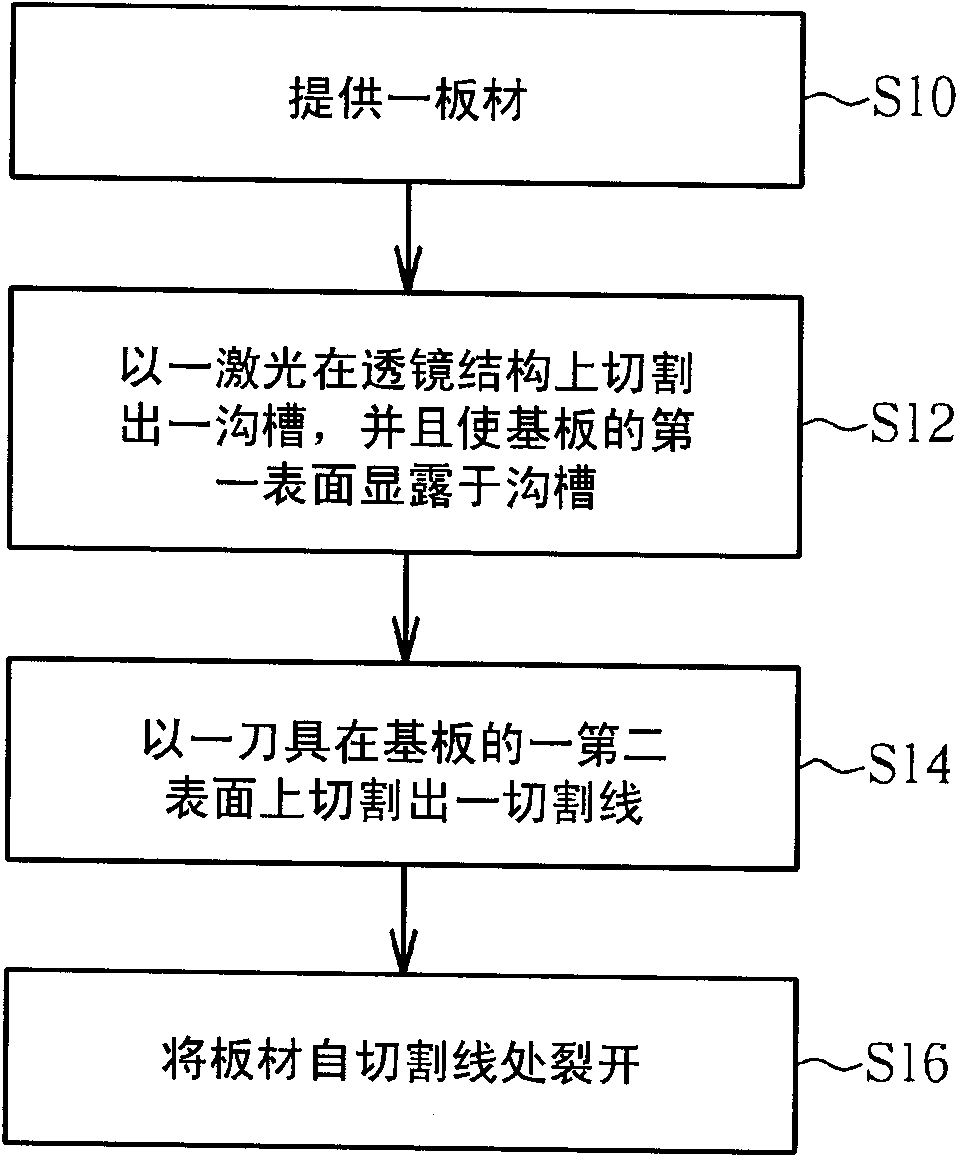

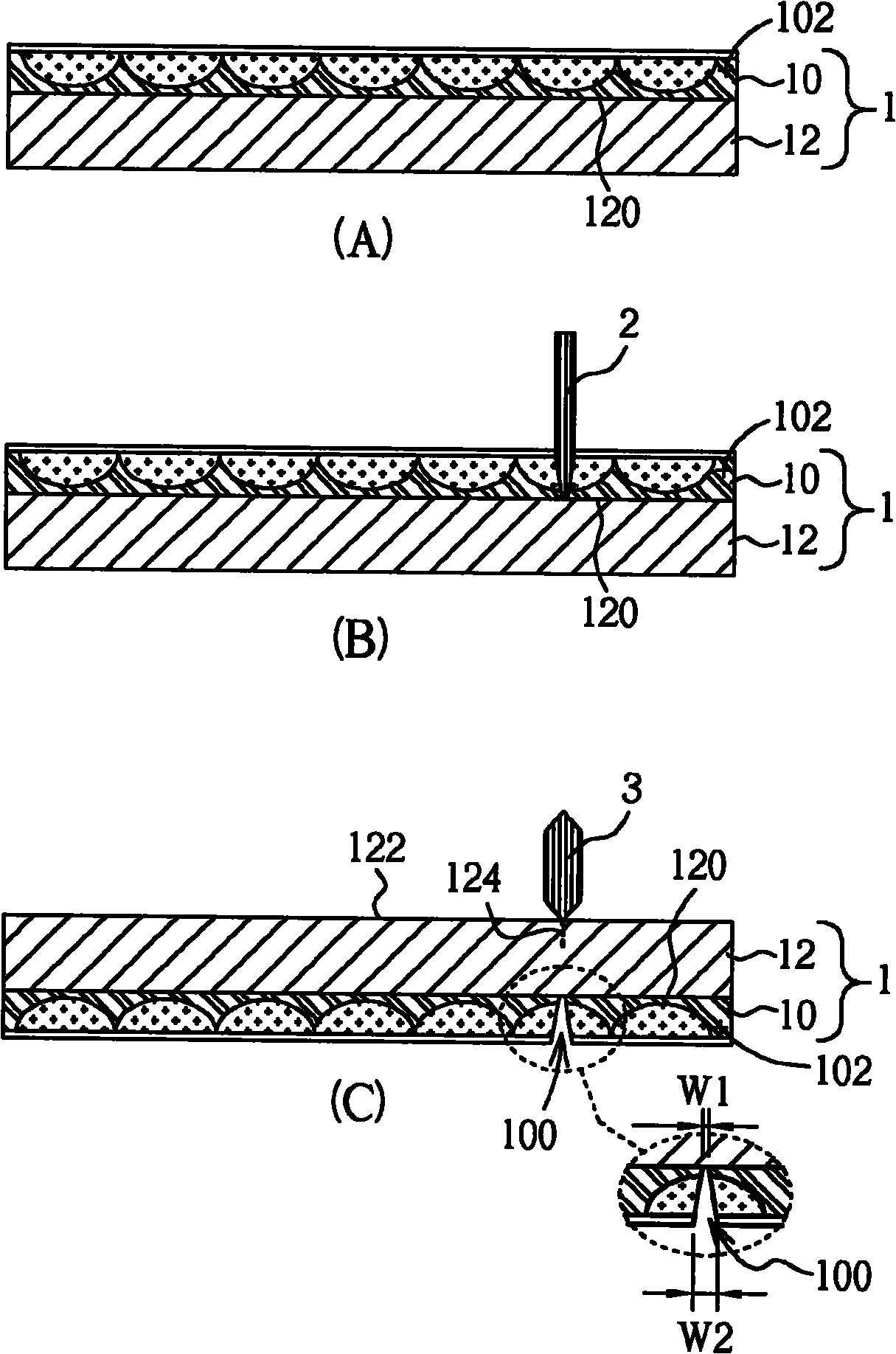

[0043] see figure 1 as well as figure 2 , figure 1 It is a flow chart of a manufacturing method of an optical module according to an embodiment of the present invention, figure 2 for matching figure 1 Schematic diagram of the process. First, step S10 is performed to provide a plate 1, wherein the plate 1 includes a lens structure 10 and a substrate 12, and the lens structure 10 is formed on a first surface 120 of the substrate 12, as figure 2 (A) shown. In this embodiment, the substrate 12 may be a glass substrate, but not limited thereto. Next, step S12 is executed, a groove 100 is cut on the lens structure 10 with a laser 2, and the first surface 120 of the substrate 12 is exposed in the groove 100, as figure 2 (B) with figure 2 (C) shown. Next, step S14 is performed, turning the board 1 over, and cutting a cutting line 124 on a second surface 122 of the substrate 12 with a cutter 3, wherein the second surface 122 is opposite to the first surface 120, and the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com